Method for treatment of oily sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as reducing resource utilization efficiency and environmental pollution, and achieve the utilization of chemicals High efficiency, great economic benefits, and the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

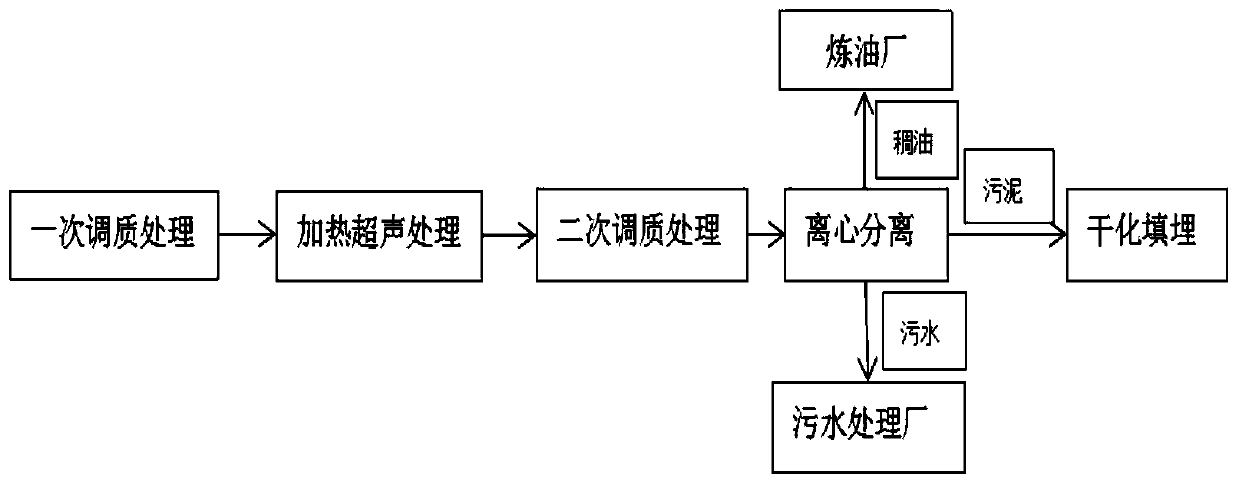

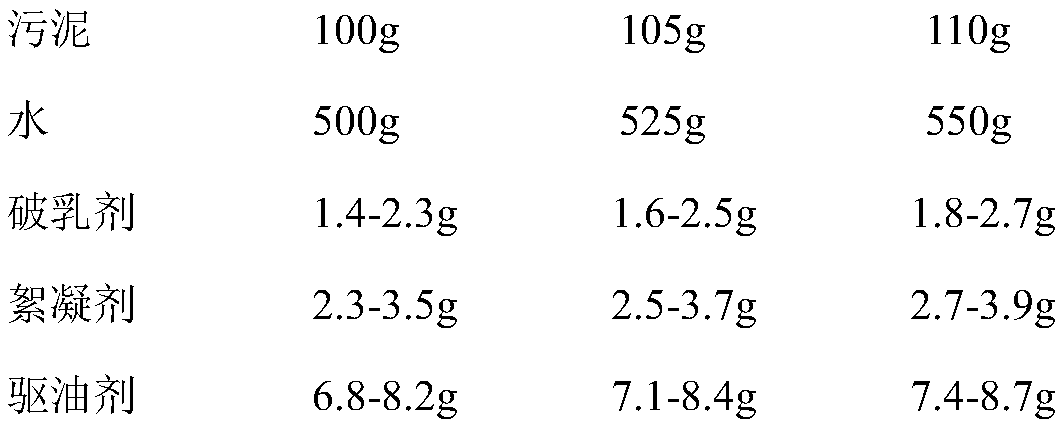

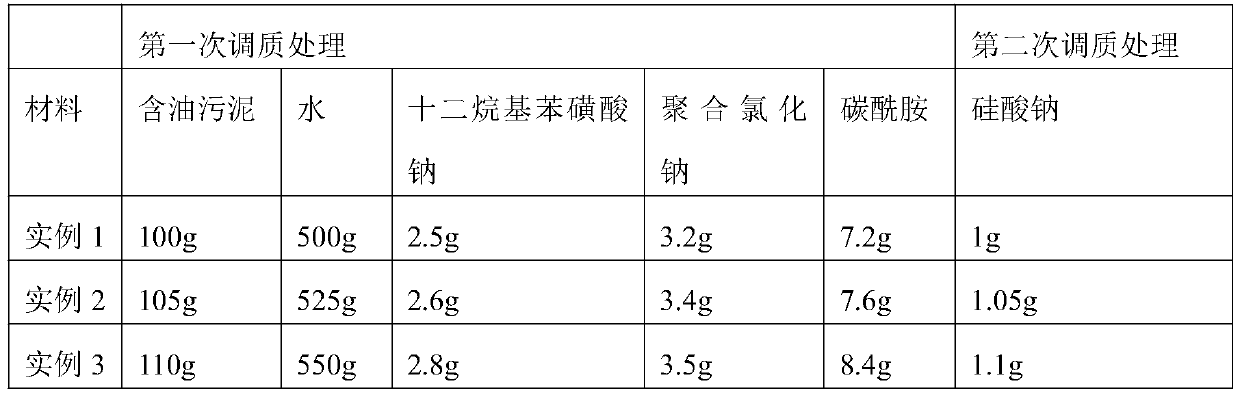

[0028] The invention relates to a method for treating oily sludge. First, the oily sludge is diluted from a viscous state to a fluid state by the first quenching and tempering treatment, followed by heating and ultrasonic treatment to initially separate water, oil, and mud into three phases , To obtain separated oil and solids, and then use the second quenching and tempering treatment for deep oil-solid separation, and finally, the oil is separated by a horizontal screw centrifugal machine, the sludge solids are dried, standing for precipitation, oil-water layer separation, crude oil Recycle and complete the treatment of oily sludge. In the whole process, two quenching and tempering treatments are carried out according to the characteristics of the sludge, the efficiency of oil washing is higher, and the utilization rate of the medicament is higher. Ultrasonic and mechanical centrifugal methods are also used to speed up the process, further improve the efficiency of oil washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com