A fluid loss reducer with anti-thickening and upside-down performance, its preparation method and application

A fluid loss reducing agent and performance technology, applied in the field of fluid loss reducing agent and its preparation, can solve the problems of weak cement stone in the lower layer, weakened ability of cement slurry to stabilize the formation, polluted oil and gas layers, etc., and achieve good high temperature resistance , to avoid the effect of viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

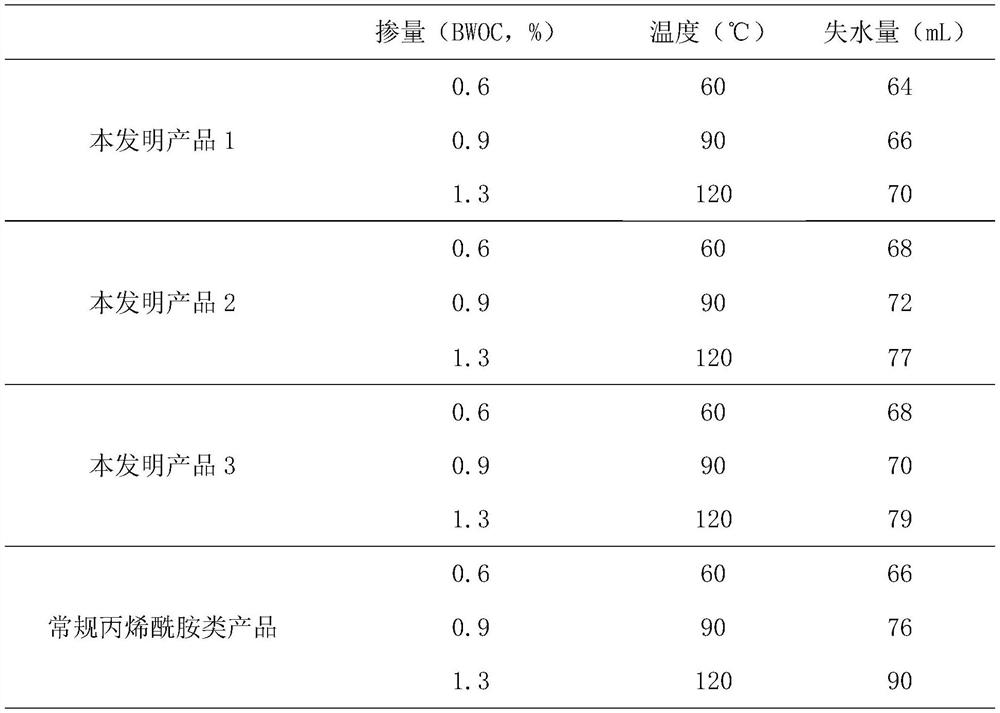

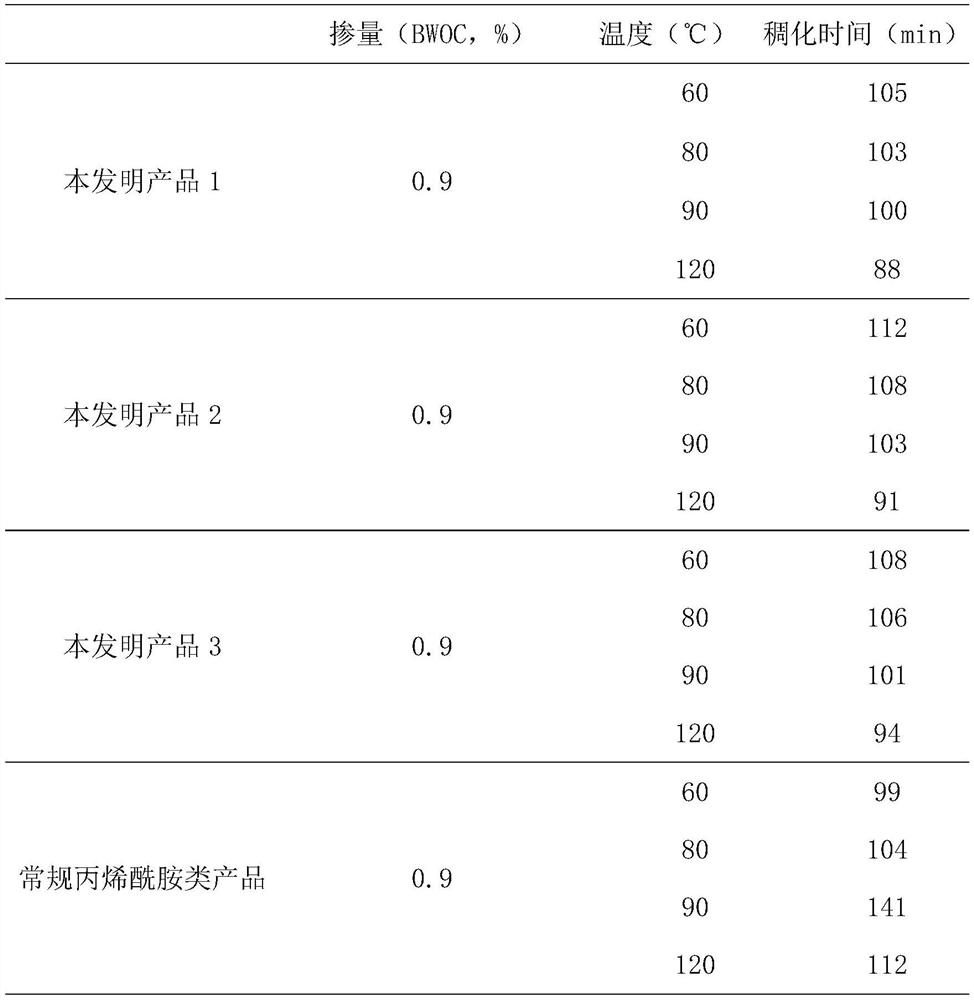

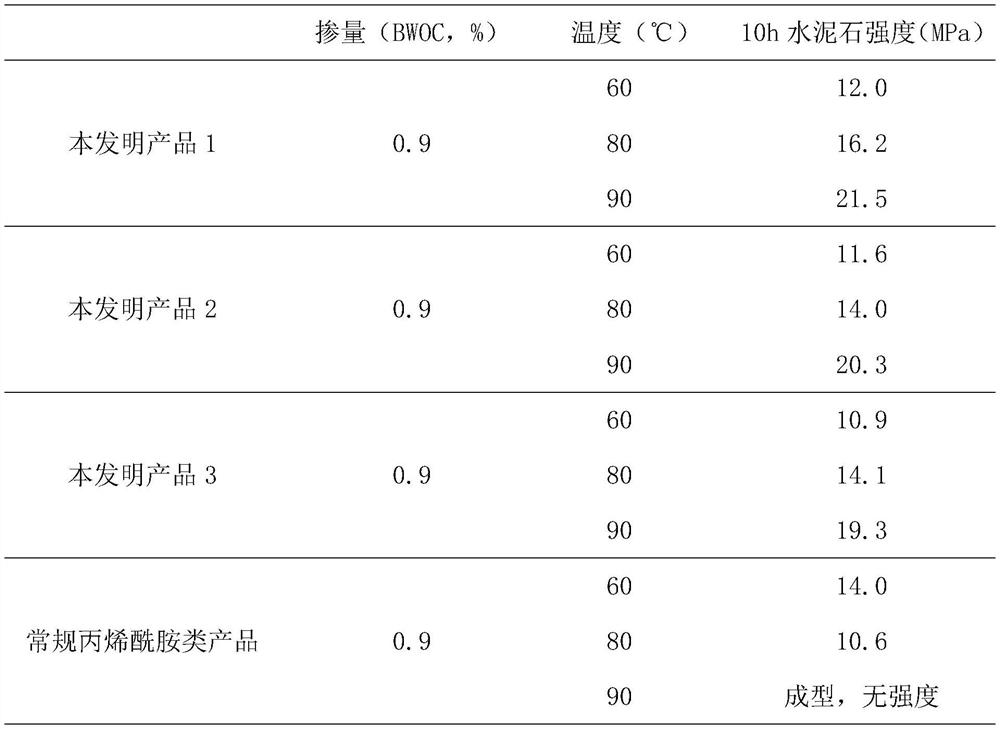

Examples

Embodiment 1

[0034] Add 950g water to the reaction kettle, add 260g AMPS under stirring, the stirring speed is 65 rpm, after fully dissolving, add 168.1g of sodium hydroxide solution with a concentration of 30%, adjust the pH value to 8.3, then add 48g ACMO, 65g DMC and 25g NVP three components and stir to dissolve. After the temperature was raised to 60° C., 27.8 g of a pre-prepared potassium persulfate solution with a concentration of 10% was added dropwise, wherein the amount of potassium persulfate added was 0.7% of the total mass of the monomer. The reaction was stirred at constant temperature at a speed of 55 rpm for 3.5 h. After the reaction is completed, the product is discharged, and the product is a light yellow viscous solution, which is dried, pulverized, and sieved to obtain a powder product with uniform particles, which is designated as product 1.

Embodiment 2

[0036] Add 750g water in reactor, add 192g AMPS under stirring, stirring speed is 65 rev / mins, after fully dissolving, add the sodium hydroxide solution 124.8g of concentration 30%, adjust pH value to be 8.7, then add 33g NIPAM, 51g TMDAAC and 24g NVP three components and stirred to dissolve. After the temperature was raised to 60° C., 24 g of a pre-prepared potassium persulfate solution with a concentration of 10% was added dropwise, wherein the amount of potassium persulfate accounted for 0.8% of the total mass of the monomer. The reaction was stirred at constant temperature at a speed of 55 rpm for 3.5 h. After the reaction is completed, the product is discharged, and the product is a light yellow viscous solution, which is dried, pulverized, and sieved to obtain a powder product with uniform particles, which is designated as product 2.

Embodiment 3

[0038] Add 800g of water to the reaction kettle, add 216g of AMPS under stirring, the stirring speed is 65 rpm, after fully dissolving, add 140.5g of 30% sodium hydroxide solution, adjust the pH value to 8.5, then add 42g of ACMO, 66g of TMDAAC in turn and 21 g of NVP three components and stirred to dissolve. After the temperature was raised to 60° C., 29.3 g of a pre-prepared 10% sodium persulfate solution was added dropwise, wherein the amount of sodium persulfate accounted for 0.85% of the total mass of the monomer. The reaction was stirred at constant temperature at a speed of 55 rpm for 3.5 h. After the reaction is completed, the product is discharged, and the product is a light yellow viscous solution, which is dried, pulverized, and sieved to obtain a powder product with uniform particles, which is designated as product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com