Preparation method of laterite nickel ore pellet

A technology of lateritic nickel ore and pellets, which is applied in the field of metallurgy, can solve the problems of difficult large-scale equipment, dust pollution, high energy consumption, etc., and achieve the effects of reducing drying costs, protecting the environment, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

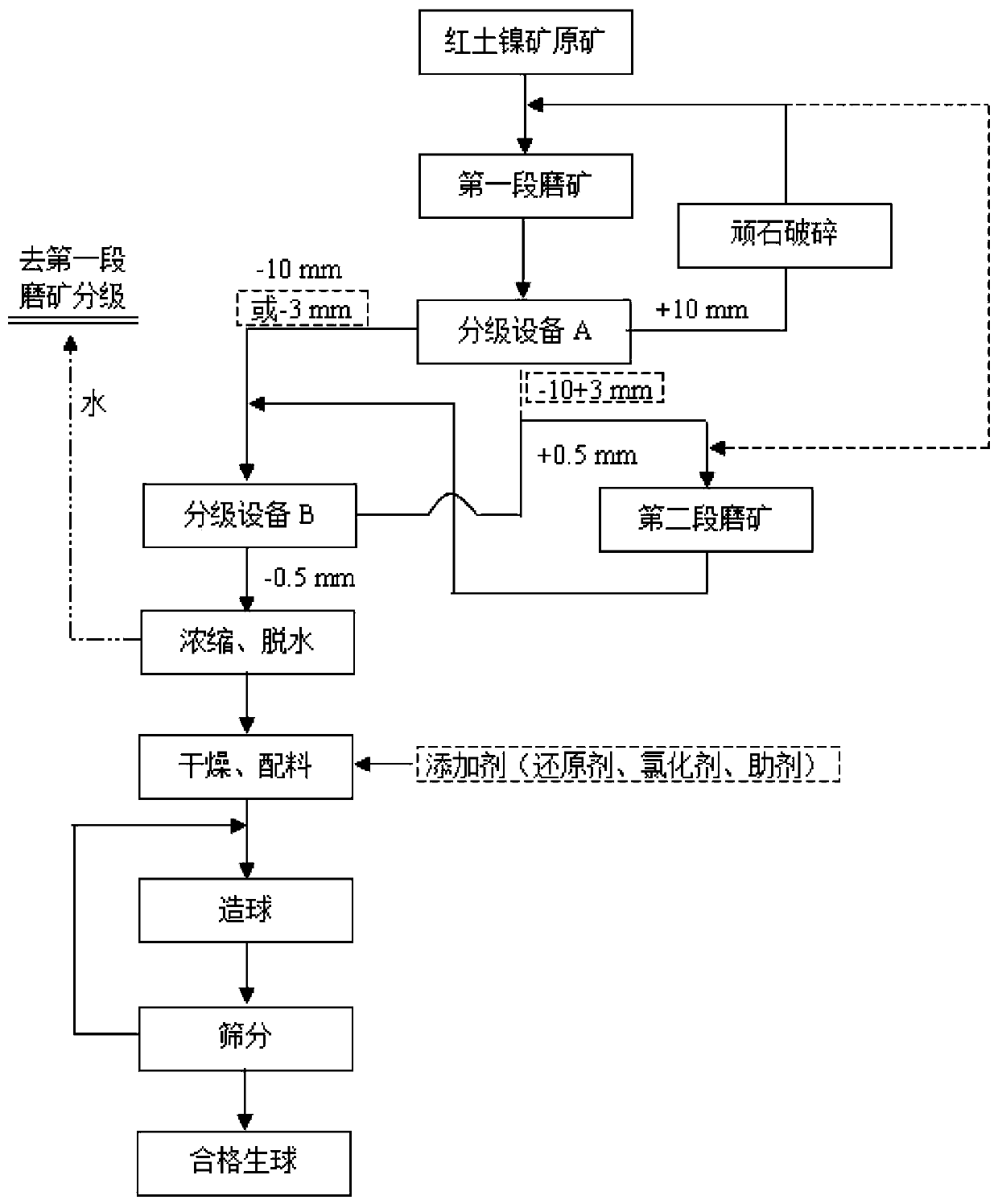

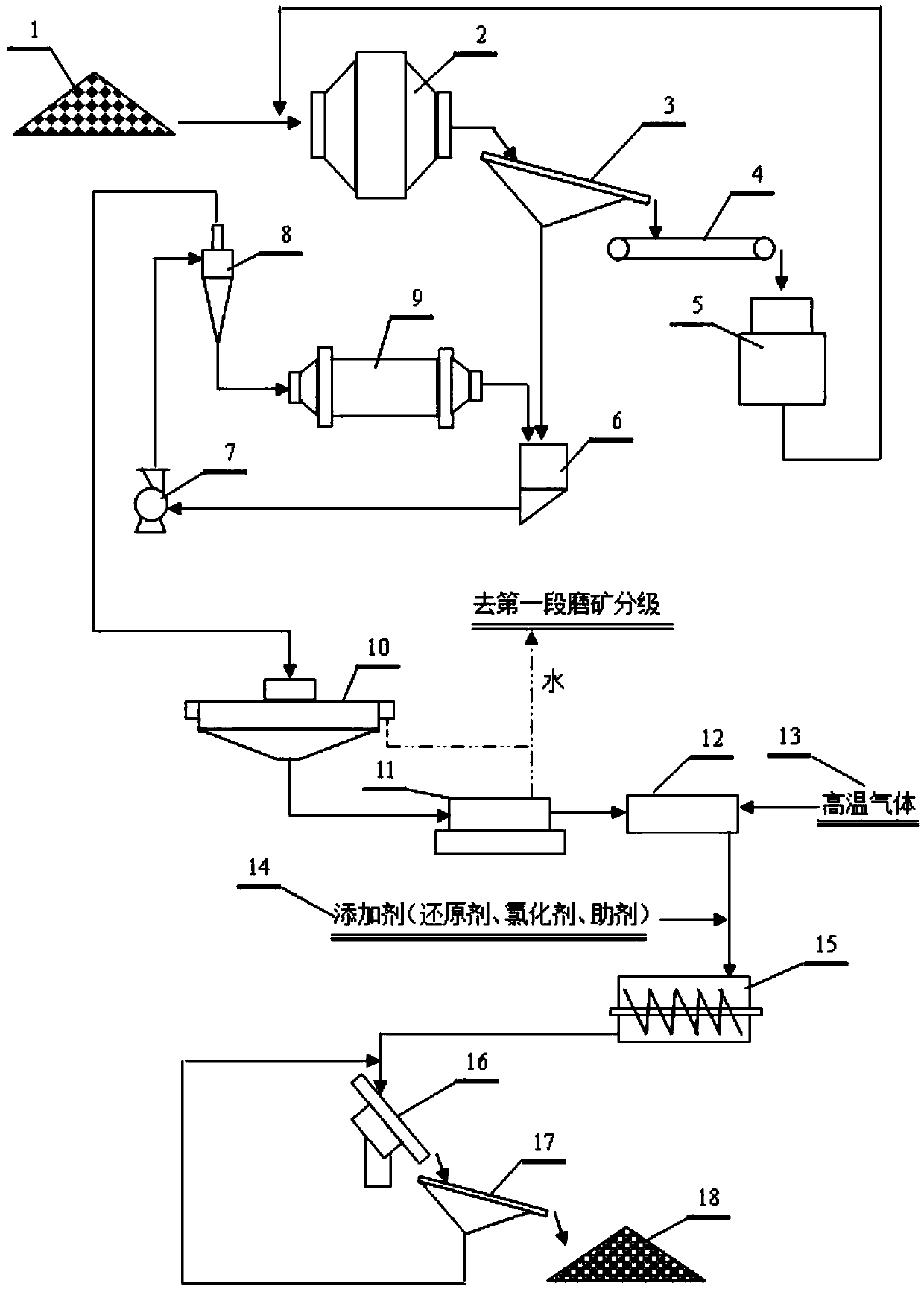

[0029] see figure 1 and figure 2 , a preparation method of laterite nickel ore pellets, comprising the steps of:

[0030] 1) Grinding and grading: Feed the laterite nickel ore 1 with a particle size of less than 350mm into the semi-autogenous mill 2, and the discharged ore is classified by the linear vibrating screen 3, and the material larger than 10mm is transported to the crusher 5 by the belt 4 and then returned to the semi-autogenous mill for crushing. Self-grinding machine 2; materials less than 10 mm are sent to cyclone 8 for classification through pump box 6 and slurry pump 7, and the cyclone sinks into ball mill 9 for grinding, and the cyclone overflow is the qualified particle size (less than 0.5 mm) pulp, the pulp moisture content is about 60%;

[0031] 2) Concentration and dehydration: For qualified pulp, thickener 10 is used to concentrate first, and then horizontal spiral sedimentation centrifuge 11 is used for dehydration to obtain materials with a moisture c...

Embodiment 2

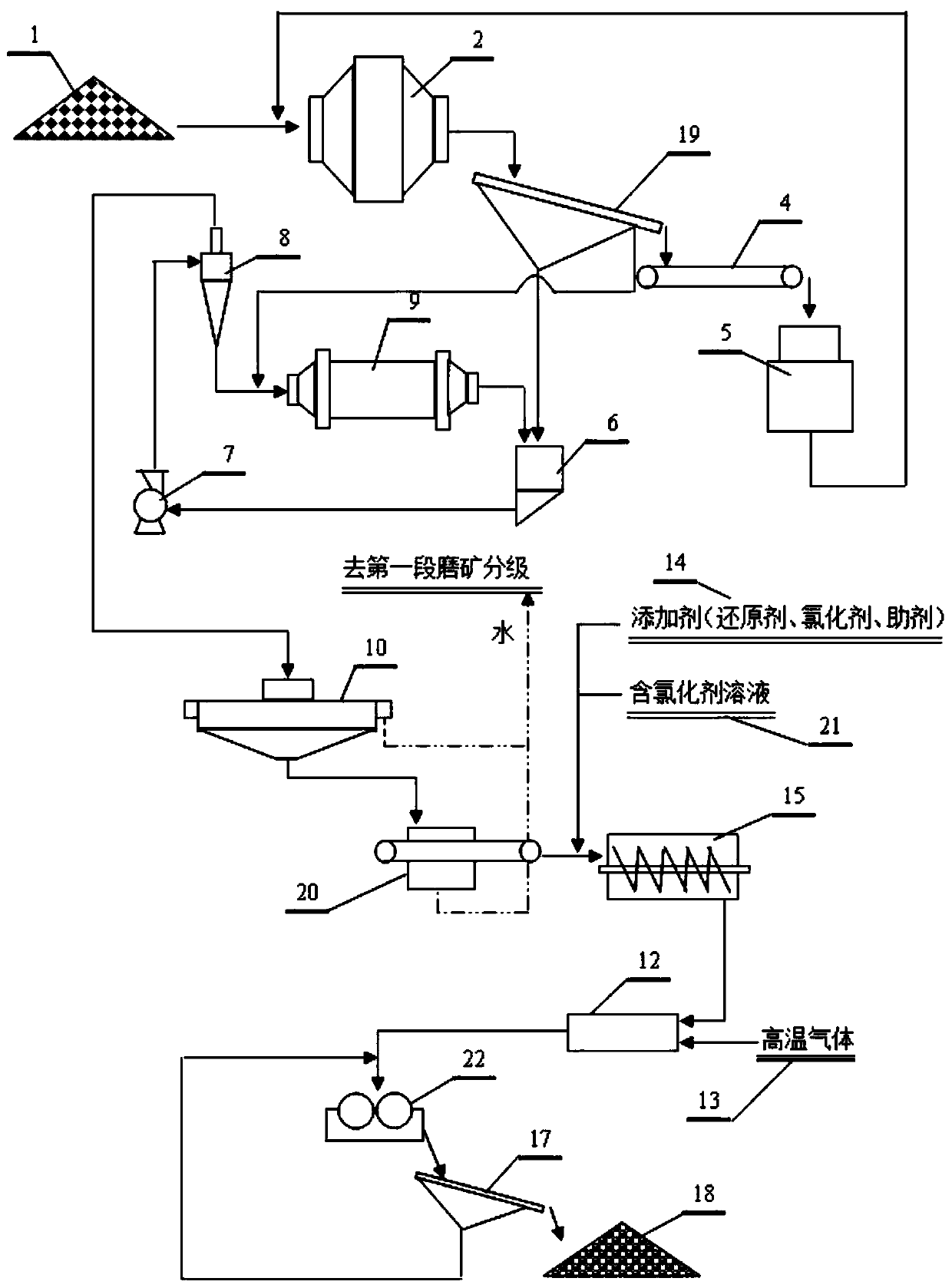

[0034] see figure 1 and image 3 , a preparation method of laterite nickel ore pellets, comprising the steps of:

[0035] 1) Grinding and grading: Feed the laterite nickel ore 1 with a particle size of less than 350 mm into the semi-autogenous mill 2, and the discharged ore is classified by the double-layer vibrating screen 19, and the material larger than 10 mm is transported to the crusher 5 through the belt 4 and returned after crushing Semi-autogenous mill 2; materials of 3-10mm enter ball mill 9 for grinding; materials less than 3mm and the ore discharge of ball mill 9 are sent to cyclone 8 for classification through pump box 6 and slurry pump 7, and cyclone settling sand Enter the ball mill 9 to grind the ore, and the cyclone overflow is the qualified particle size (less than 0.5mm) slurry, and the moisture content of the slurry is about 65%;

[0036] 2) Concentration and dehydration: For qualified pulp, thickener 10 is used to concentrate first, and then belt filter 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com