Low-titanium ferrophosphorus, preparation method and application

A high-titanium-phosphorus and titanium-phosphorus technology is applied in the field of pure ferroalloy smelting and production, which can solve the problems of high titanium content and inability to meet the production requirements of high-quality silicon steel, and achieve the effects of less environmental pollution, short process flow and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

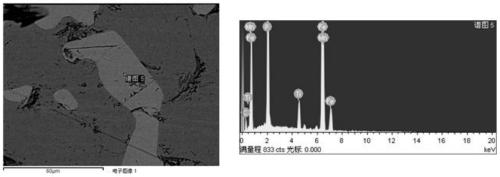

Image

Examples

Embodiment 1

[0050] Add 500 kg of high-titanium ferrophosphorus and 33 kg of adsorption slag into an intermediate frequency induction furnace for melting. The components of the high-titanium ferrophosphorus used include: P: 25%, Si: 3%, C: 1%, S : 0.05%, Mn: 1%, Cr: 0.8%, Ti: 2.2%, and the balance is Fe. The composition of the adsorption slag includes by weight: MnO: 14%, SiO 2 : 27%, CaO: 32%, Al 2 o 3 :12%, CaF 2 : 9%, FeO: 6%.

[0051] After melting, the temperature is 1500K. After melting, nitrogen blowing is started for blowing. In the first stage of blowing, the gas blowing volume is 300 liters / 100 kg of ferrophosphorus, the flow rate is controlled at 100 liters / minute, and the blowing time is 15 minutes; In the second stage, the gas blowing volume is 50 liters / 100 kg of ferrophosphorus, the flow rate is controlled at 30 liters / minute, and the blowing time is 9 minutes.

[0052] After the blowing is completed, slag is removed and iron is tapped in a molten state to obtain 480 kg ...

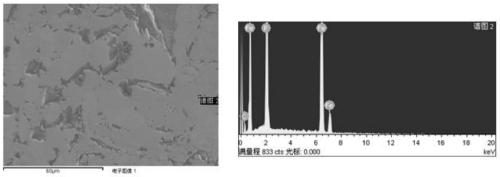

Embodiment 2

[0057] Add 500 kg of high-titanium ferrophosphorus and 45 kg of adsorption slag into an intermediate frequency induction furnace for melting. The components of the high-titanium ferrophosphorus used include by weight: P: 23%, Si: 2%, C: 0.8%, S : 0.05%, Mn: 2%, Cr: 0.9%, Ti: 1.4%, and the balance is Fe. The composition of the adsorption slag includes by weight: MnO: 12%, SiO 2 : 28%, CaO: 32%, Al 2 o 3 : 10%, CaF 2 : 10%, FeO: 8%.

[0058] After melting, the temperature is 1590K. After melting, ammonia blowing is started for blowing. In the first stage of blowing, the gas blowing volume is 500 liters / 100 kg of ferrophosphorus, the flow rate is controlled at 150 liters / minute, and the blowing time is 17 minutes. In the second stage, the gas blowing volume is 70 liters / 100 kg of ferrophosphorus, the flow rate is controlled at 45 liters / minute, and the blowing time is 8 minutes.

[0059]After the blowing is completed, remove the slag and tap the iron in the molten state. The ...

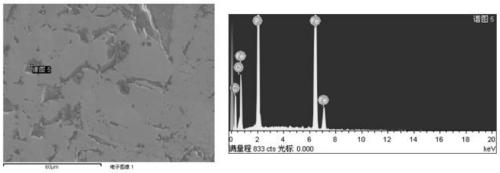

Embodiment 3

[0063] 500 kg of high-titanium ferrophosphorus and 62.5 kg of adsorption slag were added to an intermediate frequency induction furnace for melting. The components of the high-titanium ferrophosphorus used included by weight: P: 23%, Si: 2%, C: 0.8%, S : 0.05%, Mn: 2%, Cr: 0.9%, Ti: 1.4%, and the balance is Fe. The composition of the adsorption slag includes by weight: MnO: 12%, SiO 2 : 26%, CaO: 31%, Al 2 o 3 : 12%, CaF 2 : 9%, FeO: 10%.

[0064] After melting, the temperature is 1650K. After melting, ammonia blowing is started for blowing. The first stage of blowing is 800 liters / 100 kg of high-titanium ferrophosphorus. The flow rate is controlled at 200 liters / minute, and the blowing time is 20 minute. In the second stage, the gas blowing volume is 100 liters / 100 kg high-titanium ferrophosphorus, the flow rate is controlled at 50 liters / minute, and the blowing time is 10 minutes.

[0065] After the blowing is completed, 470 kg of low-titanium ferrophosphorus with a tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com