A flexible packaging material for printing ink and its preparation method

A printing ink and flexible packaging technology, applied in paper coating, non-pigment coating, fiber raw material processing, etc., can solve the problems of inability to adapt to the new continuous printing process, inability to recycle and reuse, high transportation costs, etc., and achieve water vapor transmission Low efficiency, easy recycling, no ink penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

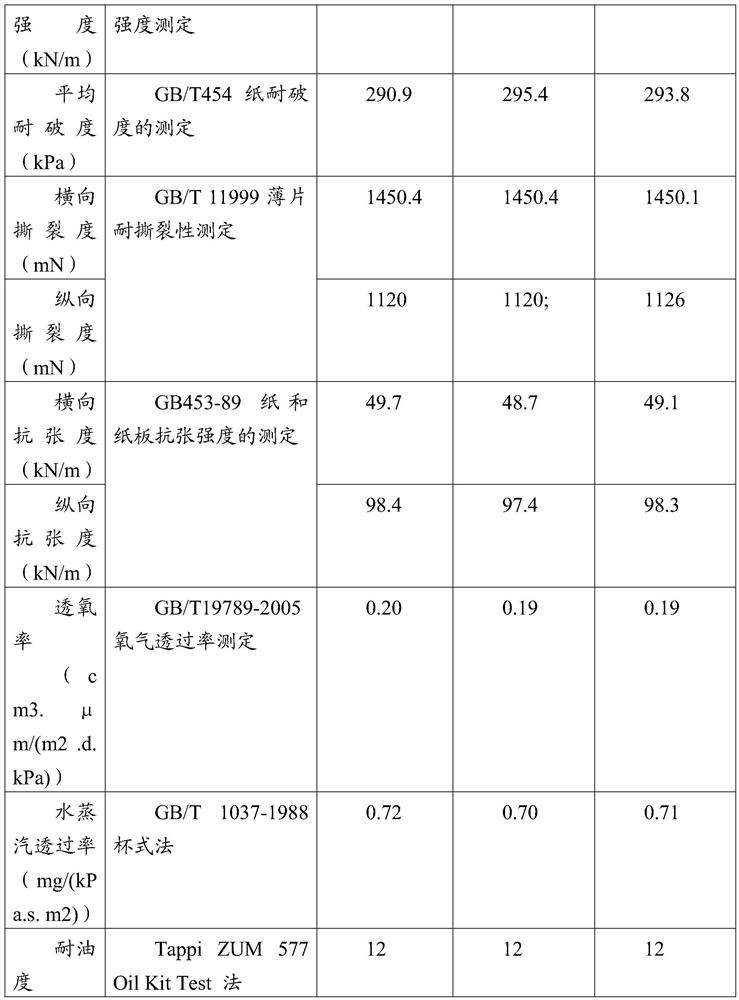

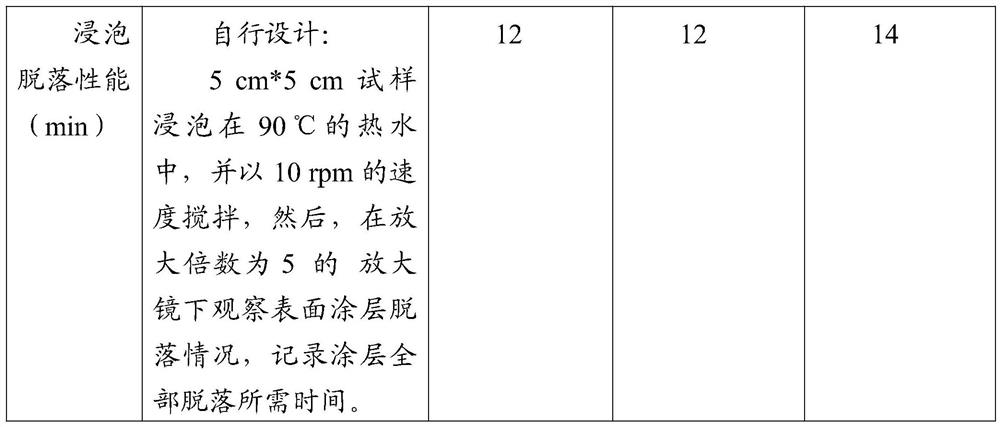

Embodiment 1

[0049] The flexible packaging material used for printing ink of the present invention has a size of 30cm*42cm, 125g / m 2 3 sheets of natural kraft wrapping paper; and weigh 40 g of granular polyethylene glycol with a model number of 2488; at the same time, weigh 26.7 g of a hydrogel with a nanocellulose content of 3%, the nanocellulose contained in the hydrogel The width is 10-30nm and the length is 100-500nm.

[0050] The preparation method of the above-mentioned flexible packaging material for printing ink is as follows:

[0051] Step (1): under stirring, slowly and gradually add polyethylene glycol into water with a temperature of 20° C. and a mass of 335 g, and then continue stirring for 24 h to obtain a polyethylene glycol solution with a concentration of 10%;

[0052] Step (2): in the polyethylene glycol solution in step (1), add nanocellulose crystal hydrogel, continue stirring for 2h, and then ultrasonically treat for 10min to obtain a PVA / CNC mixed solution;

[0053]...

Embodiment 2

[0058] The flexible packaging material used for printing ink of the present invention has a size of 30cm*42cm, 125g / m 2 3 sheets of natural kraft wrapping paper; and weigh 20 g of granular polyethylene glycol with a model number of 2488; at the same time, weigh 26.7 g of a hydrogel with a nanocellulose content of 3%, the nanocellulose contained in the hydrogel The width is 10-30nm and the length is 100-500nm.

[0059] The preparation method of the above-mentioned flexible packaging material for printing ink is as follows:

[0060] Step (1): under stirring, slowly and gradually add polyethylene glycol into water with a temperature of 25°C and a mass of 353 g, and then continue stirring for 18 h to obtain a polyethylene glycol solution with a concentration of 5%;

[0061] Step (2): in the polyethylene glycol solution in step (1), add nanocellulose crystal hydrogel, continue stirring for 1h, and then ultrasonically treat for 6min to obtain a PVA / CNC mixed solution;

[0062] Step ...

Embodiment 3

[0067] The flexible packaging material used for printing ink of the present invention has a size of 30cm*42cm, 125g / m 2 3 sheets of natural kraft wrapping paper; and weigh 20 g of granular polyethylene glycol with a model number of 2488; at the same time, weigh 53.4 g of a hydrogel with a nanocellulose content of 3%, the nanocellulose contained in the hydrogel The width is 10-30nm and the length is 100-500nm.

[0068] The preparation method of the above-mentioned flexible packaging material for printing ink is as follows:

[0069] Step (1): under stirring, slowly and gradually add polyethylene glycol into water with a temperature of 25°C and a mass of 178 g, and then continue stirring for 12 h to obtain a polyethylene glycol solution with a concentration of 8%;

[0070] Step (2): in the polyethylene glycol solution in step (1), add nanocellulose crystal hydrogel, continue stirring for 2h, and then ultrasonically treat for 8min to obtain a PVA / CNC mixed solution;

[0071] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com