Oil well non-flowback working fluid and steering and energizing integrated completely-closed acidizing construction technology

A technology of construction technology and working fluid, applied in the fields of production fluids, wellbore/well components, chemical instruments and methods, etc., can solve the problems of long construction period, affecting normal production, aggravating the stuck pump and broken rod of production wells, etc. Solve residual acid corrosion, improve production stimulation effect, and improve the effect of oil well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] Specific embodiments: the present invention will be further described in conjunction with the following examples: a kind of oil well non-flowback working fluid and a fully enclosed acidification construction process integrated with steering and energy enhancement, and its oil well non-flowback working fluid consists of pre-fluid, Composed of acid liquid, steering fluid, treatment fluid, and energizing fluid; the pre-fluid is composed of 4-8% high-efficiency oil cleaning agent and the rest of hot water; the acid liquid is composed of 10-15% hydrochloric acid, 1-2.0% ammonium fluoride, 1-2% glacial acetic acid, 0.1-0.15% citric acid, 0.3-0.6% YC-II type imidazoline corrosion inhibitor synthesized in house and the rest of water; the steering liquid is composed of 5- 15% sodium carboxymethyl cellulose and the rest of the acid liquid; the treatment liquid is composed of 3-12% sodium hydroxide and the rest of the water; the energy-enhancing liquid is composed of 0.2-0.3% cocon...

Embodiment

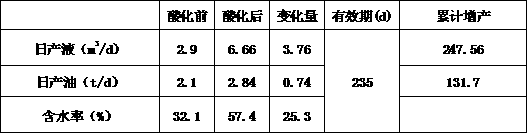

[0029] Example: This example is a fully closed test of Gao 171-1 Well of Daqing Oil Production No. 7 Factory without flowback. 2% OP-10, 4% octylphenol polyoxyethylene ether and the rest of water; the acid solution consists of 12% hydrochloric acid, 1.5% ammonium fluoride, 1% glacial acetic acid, 0.15% citric acid, 0.5 %Indoor synthesis of YC-II imidazoline corrosion inhibitor and the rest of the water; the steering liquid is composed of 10% sodium carboxymethylcellulose and the rest of the acid; the treatment liquid is composed of 4% sodium hydroxide and the balance of water; the energy-enhancing liquid is composed of 0.2% coconut acid diethanolamide, 0.3% heavy alkylbenzene sulfonate and the balance of water; a kind of non-flowback working fluid for steering and energy-enhancing integration The chemical fully enclosed acidification construction process is realized through the following steps:

[0030] a. Squeeze 4m of pre-fluid from the casing gate 3 ;Close the valve of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com