Buried steam pipeline system used for improving saline-alkali soil and method for improving saline-alkali soil

A steam pipeline and soil improvement technology, applied in the field of soil remediation, can solve the problems of waste of water resources, large economic investment, pollution of groundwater and downstream water bodies, etc., to increase soil organic matter content, increase emergence rate and yield, and increase functional diversity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

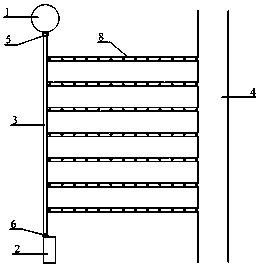

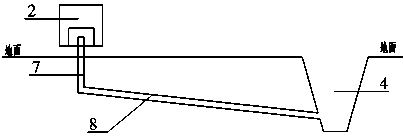

[0027] Such as figure 1 As shown, a buried steam pipeline system for improving saline-alkali soil, including a steam boiler 1, a water pump 2 and a main pipe 3 on one side of the surface of the saline-alkali soil, and the other side of the saline-alkali soil A drainage ditch 4 is provided, one end of the main pipe 3 is connected to the outlet of the steam boiler 1, the end of the main pipe 3 connected to the steam boiler 1 is provided with a steam valve 5, and the other end of the main pipe 3 is connected to the water pump 2, the end of the main pipe 3 connected to the water pump 2 is provided with a flow valve 6, and the main pipe 3 is connected with several vertical pipes 7 downwards in the vertical direction, and the vertical pipes 7 extend downwards to Inside the soil, the lower end of the vertical pipe 7 is connected with a number of horizontal pipes 8 with holes, and the horizontal pipes 8 extend obliquely downward into the drainage ditch 4 .

[0028] The following is a...

Embodiment 2

[0036] The following is an example of saline-alkali soil in Xinghualing District, Taiyuan City. Taking soil samples, the salt content of saline-alkali soil in the landscape area of this area is 0.5% to 3.1%, and the pH value is 7.9 to 9.1. The degree of oxidation is 15% to 30%.

[0037] First of all, in February, the saline-alkali soil was rotary plowed with a rotary plow at a depth of 30 cm, and then open ditches were dug on both sides of the saline-alkali soil with a depth of 30 cm. Irrigation channel: inject water into the irrigation channel, discharge water to both sides to wash in turn, and drain the saline water through the open ditch, dry the saline-alkali soil after washing, and plow it again until the soil is loose.

[0038] Then use the buried steam pipeline system to carry out secondary salt washing to the saline-alkali soil, and the buried steam pipeline system for improving the saline-alkali soil is completely laid, and the horizontal pipe 8 with holes in the sy...

Embodiment 3

[0044] The following is an example of saline-alkali soil in Xiaodian District, Taiyuan City. The salinity of the saline-alkali soil in the landscape area of this area is measured by taking soil samples. The salt content is 0.6% to 3.5%, and the pH is 8.0 to 9.1. The degree is 12% to 28%.

[0045] Firstly, rotary plows were used for saline-alkali soil in February, and the depth of the rotary plow was 50 cm. Then, open ditches were dug on both sides of the saline-alkali soil. The depth of the ditches was 50 cm. Irrigation channel: inject water into the irrigation channel, discharge water to both sides to wash in turn, and drain the saline water through the open ditch, dry the saline-alkali soil after washing, and plow it again until the soil is loose.

[0046] Then use the buried steam pipeline system to carry out secondary salt washing to the saline-alkali soil, and the buried steam pipeline system for improving the saline-alkali soil is completely laid, and the horizontal pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com