Sludge anaerobic fermentation treatment method synchronously enhancing acid production and phosphorus removal

A technology of sludge anaerobic fermentation and treatment method, applied in the field of excess sludge anaerobic treatment, can solve the problems of large release of phosphorus, reduced phosphorus release, low efficiency of organic matter conversion to short-chain fatty acids, etc. The effect of producing acid by oxygen fermentation, reducing the content of orthophosphoric acid and alleviating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

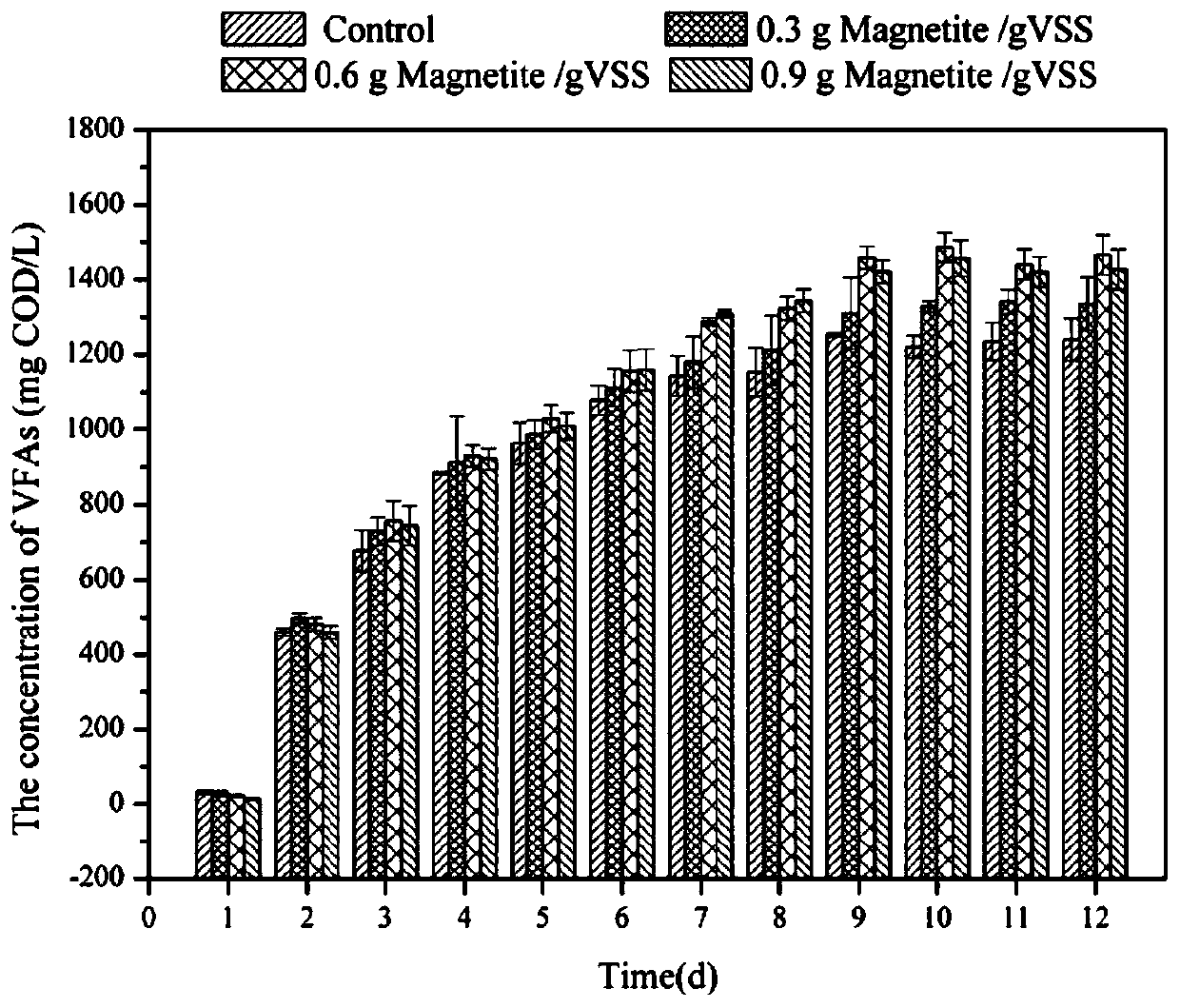

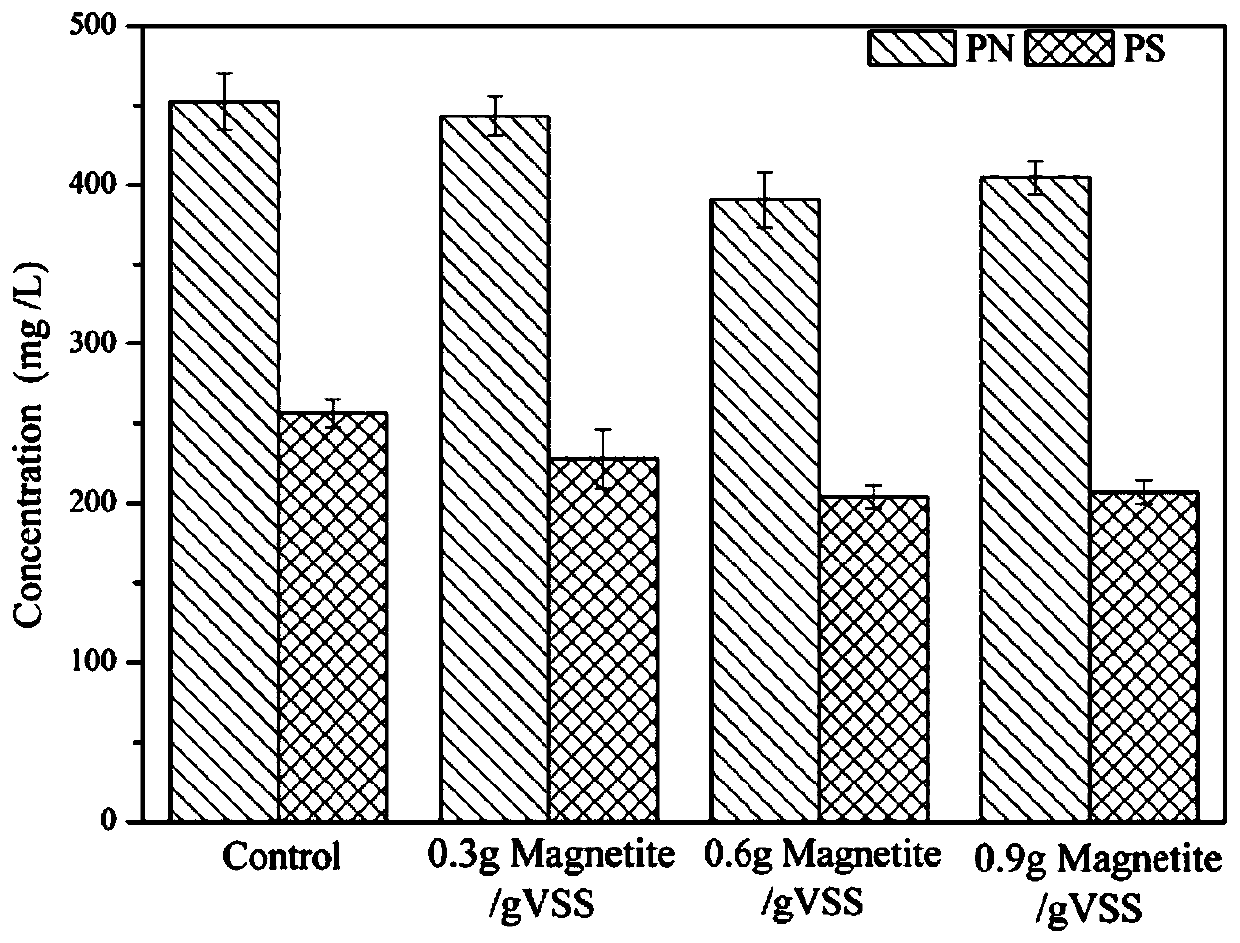

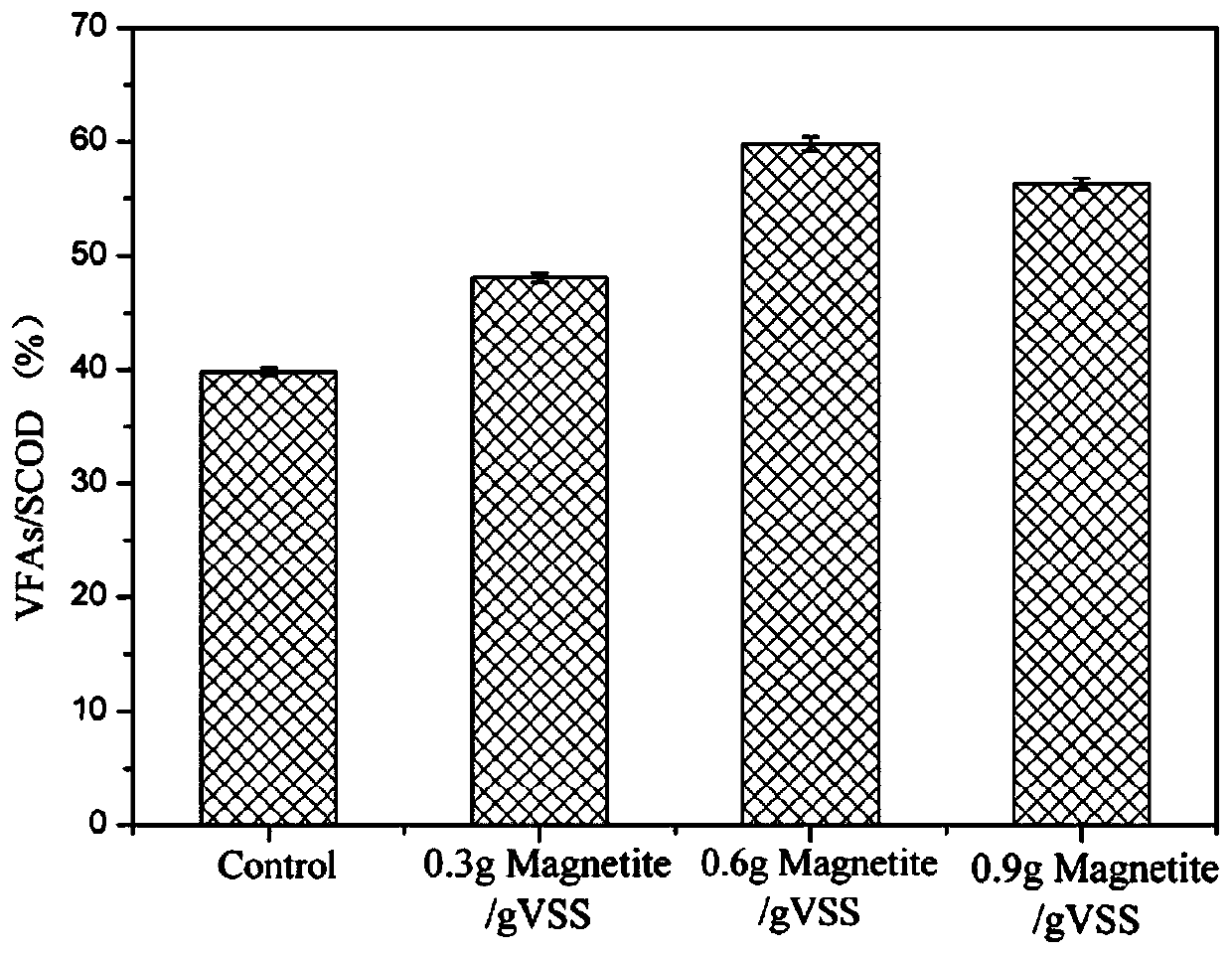

Embodiment 1

[0029] In this embodiment, the sludge anaerobic fermentation method for synchronously strengthening acid production and phosphorus removal, the steps are as follows:

[0030] (1) Take 500mL concentrated anaerobic-anoxic-aerobic (A 2 O) The remaining sludge in the process (total suspended solids concentration is 14910mg / L, volatile suspended solids concentration is 6280mg / L, pH=6.83) is added in the reactor, and the sodium hydroxide solution of 2mol / L is used to remove the remaining sludge Adjust the pH to 10, add magnetite to the excess sludge, and the dosage of magnetite is 0.3g / gVSS. Nitrogen was introduced into the excess sludge for 5 minutes to remove the air, and then the closed reactor was stirred for anaerobic fermentation, the fermentation temperature was 35°C, and the stirring speed of the reactor was 120r / min;

[0031] (2) Use 2mol / L sodium hydroxide solution during the reaction to maintain the pH of the reactor at 10±0.1.

[0032] After 10 days of fermentation, th...

Embodiment 2

[0034] In this embodiment, the sludge anaerobic fermentation method for synchronously strengthening acid production and phosphorus removal, the steps are as follows:

[0035] (1) Take 500mL concentrated anaerobic-anoxic-aerobic (A 2 O) The remaining sludge in the process (total suspended solids concentration is 14910mg / L, volatile suspended solids concentration is 6280mg / L, pH=6.83) is added in the reactor, and the sodium hydroxide solution of 2mol / L is used to remove the remaining sludge Adjust the pH to 10, add magnetite to the excess sludge, and the dosage of magnetite is 0.6g / gVSS. Nitrogen was introduced into the excess sludge for 5 minutes to remove the air, and then the closed reactor was stirred for anaerobic fermentation, the fermentation temperature was 35°C, and the stirring speed of the reactor was 120r / min;

[0036] (2) Use 2mol / L sodium hydroxide solution during the reaction to maintain the pH of the reactor at 10±0.1.

[0037] After 10 days of fermentation, th...

Embodiment 3

[0039] In this embodiment, the sludge anaerobic fermentation method for synchronously strengthening acid production and phosphorus removal, the steps are as follows:

[0040] (1) Take 500mL concentrated anaerobic-anoxic-aerobic (A 2 O) The remaining sludge in the process (total suspended solids concentration is 14910mg / L, volatile suspended solids concentration is 6280mg / L, pH=6.83) is added in the reactor, and the sodium hydroxide solution of 2mol / L is used to remove the remaining sludge Adjust the pH to 10, add magnetite to the excess sludge, and the dosage of magnetite is 0.9g / gVSS. Nitrogen was introduced into the excess sludge for 5 minutes to remove the air, and then the closed reactor was stirred for anaerobic fermentation, the fermentation temperature was 35°C, and the stirring speed of the reactor was 120r / min;

[0041] (2) Use 2mol / L sodium hydroxide solution during the reaction to maintain the pH of the reactor at 10±0.1.

[0042] (3) After 10 days of fermentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com