Silicon-oxide-based microwave dielectric ceramic with low dielectric constant and preparation method of microwave dielectric ceramic

A technology of microwave dielectric ceramics and low dielectric constant, which is applied in the field of low dielectric constant microwave dielectric ceramics and its preparation, can solve the problems of dielectric constant improvement, difficulty in preparing crack-free dense ceramics, etc., and achieve small resonant frequency temperature coefficient and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited to the examples.

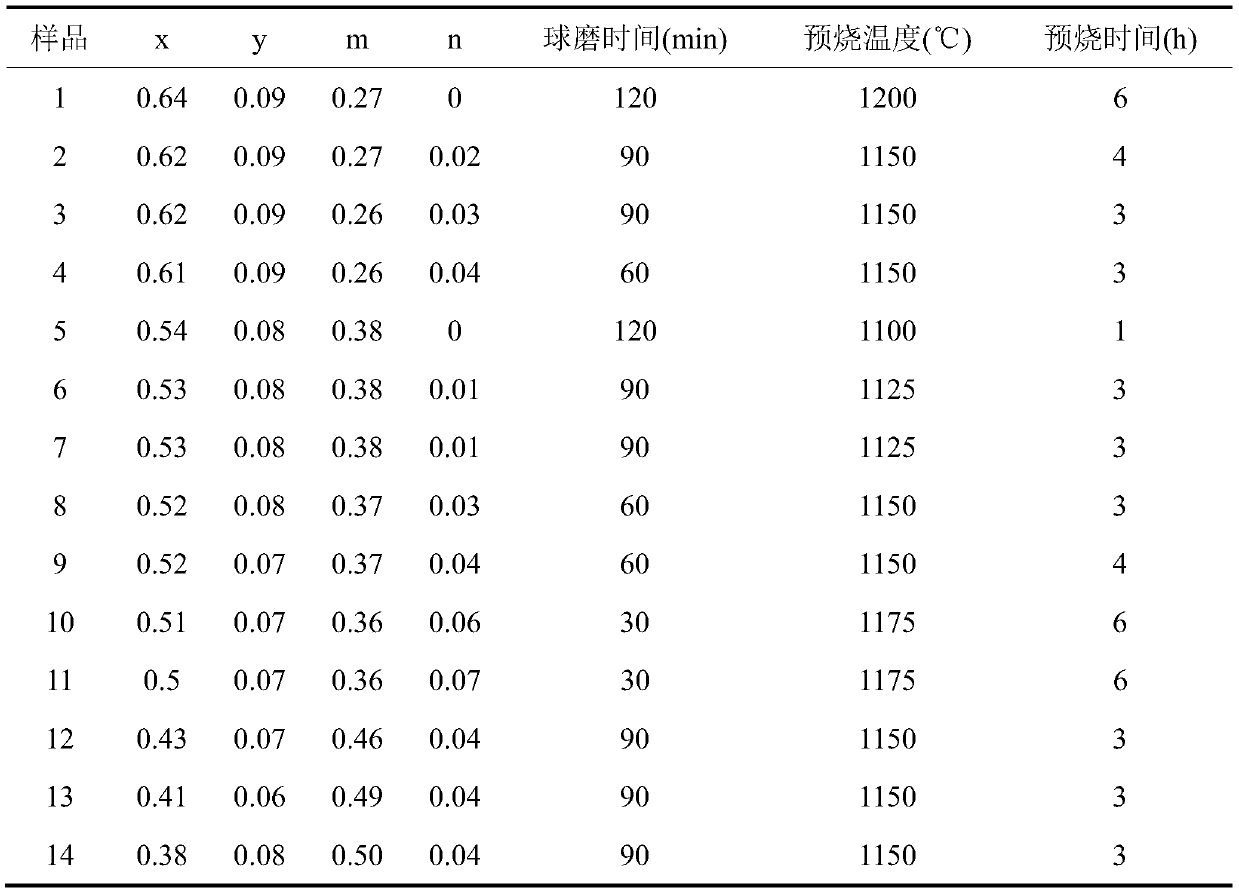

[0028] Table 3 is the chemical composition expression xZnO-yAl 2 o 3 -mSiO 2 -nSrTiO 3 Table of microwave dielectric properties of dielectric ceramics, where x, y, m, n represent ZnO, Al respectively 2 o 3 , SiO 2 , SrTiO 3 The molar ratio of x, y, m, n in each embodiment is shown in Table 3.

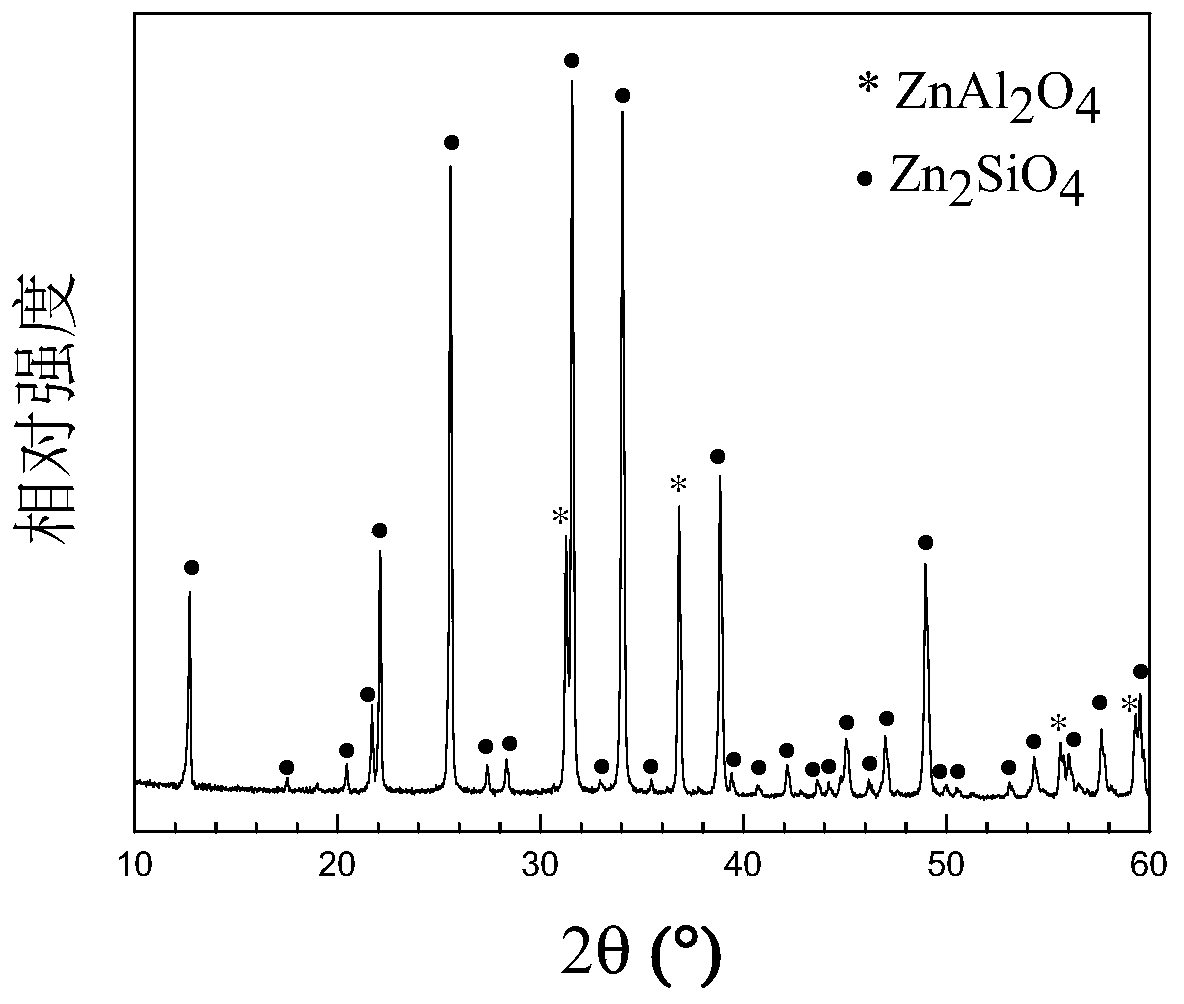

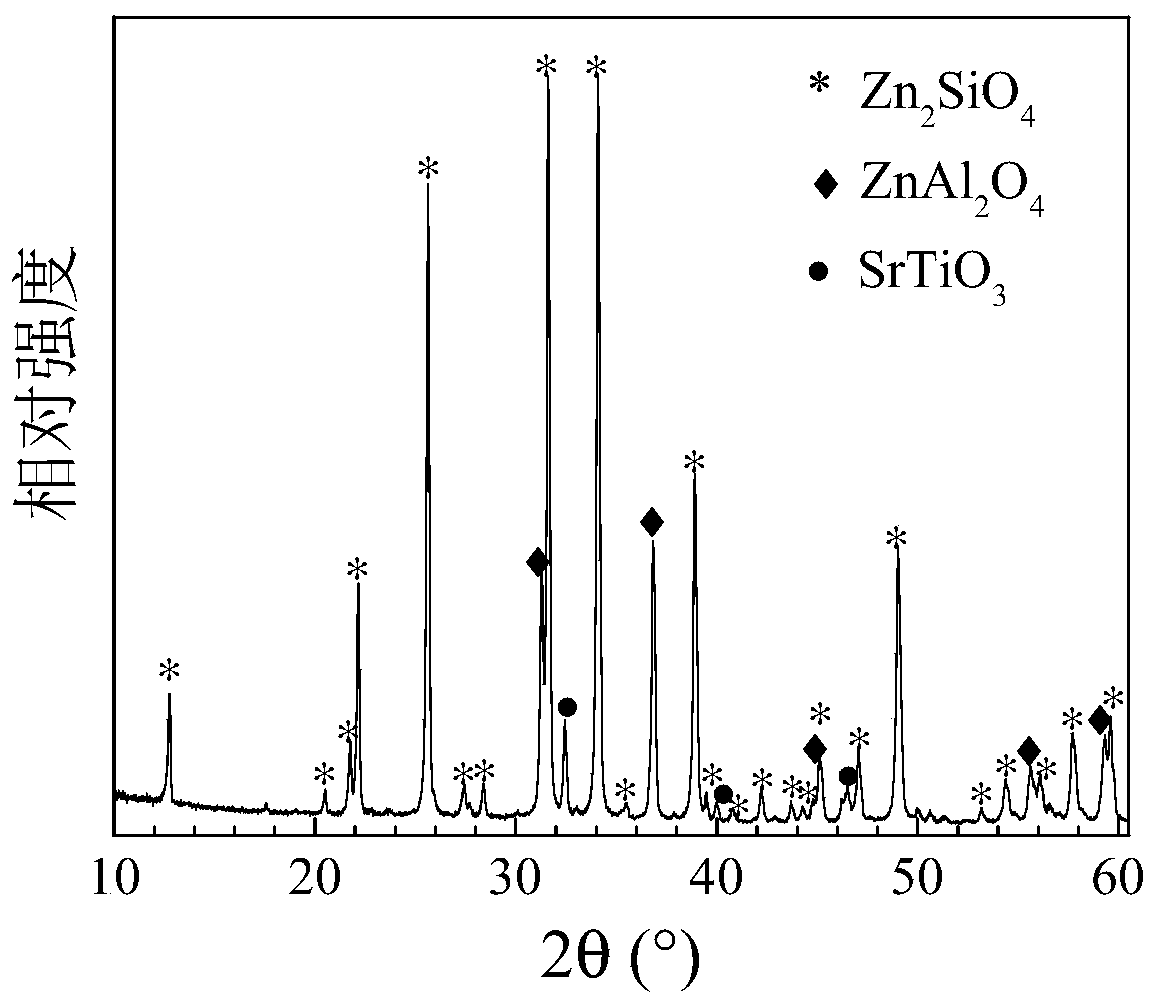

[0029] (1) Expression xZnO-yAl according to chemical composition 2 o 3 -mSiO 2 The stoichiometric ratio weighs ZnO and Al with a purity of 99.9% 2 o 3 , SiO 2 Raw material powder, planetary ball mill (solvent is alcohol, rotating speed is 300 rpm), pre-fired in air atmosphere after drying to get xZnO-yAl 2 o 3 -mSiO 2 Ceramic intermediate powder, its phase is as figure 1 (with the 0.64ZnO-0.09Al that embodiment 1 makes 2 o 3 -0.27SiO2 2as an example). Wherein, the planetary ball mill i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com