Methanol synthesizing device and method of using methanol synthesizing device for synthesizing methanol

A methanol synthesis and methanol technology, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of small loading of single-column synthesis catalysts, high effective carbon in purge gas, and low conversion rate per pass. , to achieve the effect of improving the overall operating efficiency, improving the C conversion rate, and reducing the pressure of the synthesis system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

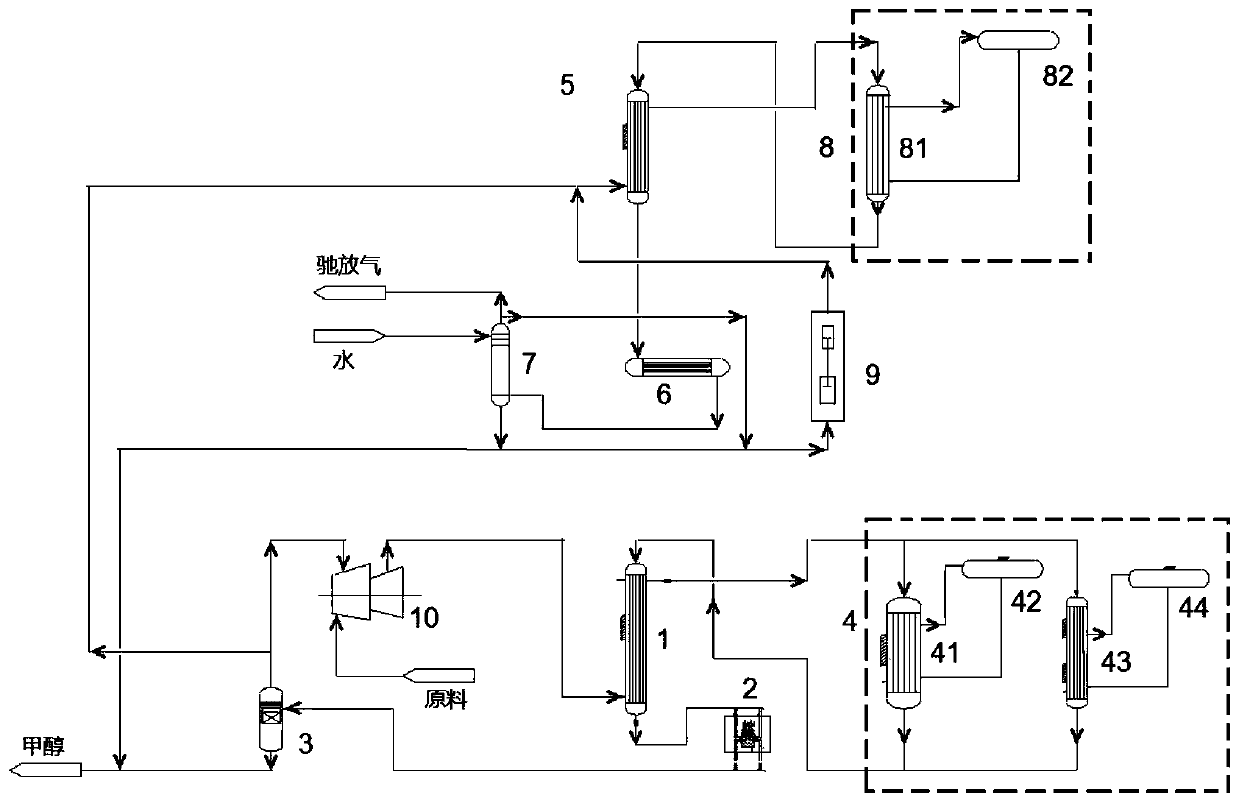

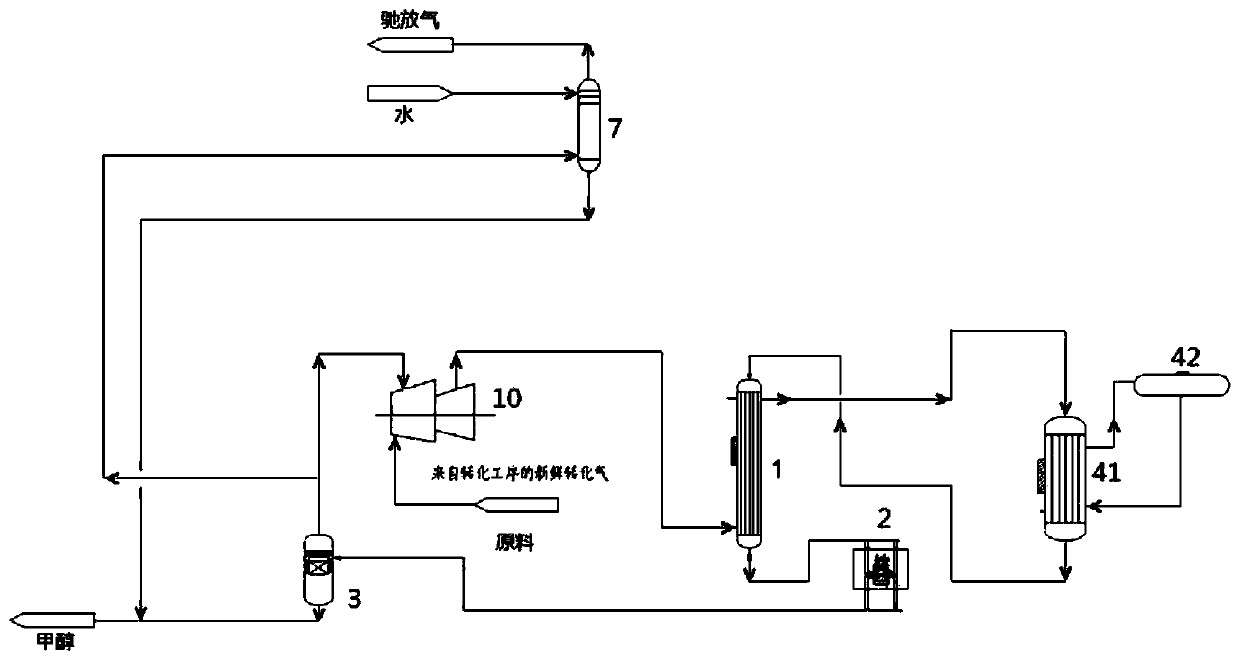

[0066] like figure 1 The setup for methanol synthesis is shown. Based on the original single-tower synthesis system, the device is connected in parallel with a second synthesis tower (43) to reduce the space velocity and increase the single-pass conversion rate of total carbon. Simultaneously, the outlet of the original exhaust gas is connected in series with the third synthesis tower (81).

[0067] In this methanol synthesis unit (200,000 tons / year), the catalyst content of the first synthesis tower (41) is 40 cubic meters, and the synthesis gas space velocity is 10000h -1 , the reaction pressure is 6.9Mpa, the reaction temperature is 200-250°C, the catalyst content of the second synthesis tower is 20 cubic meters, and the synthesis gas space velocity is 10000h -1 , reaction, synthesis gas space velocity is 6500h -1 , the reaction pressure is 5.5-6.0Mpa, the reaction temperature is 200-250°C, the catalyst content of the third synthesis tower is 4-6 cubic meters, and the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com