Cable protective sleeve

A cable protection and ultraviolet technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems that the cable sheath material is not resistant to high temperature, the waterproofness is not ideal, and the cable cannot be protected, and achieves excellent mechanical properties, good water resistance, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

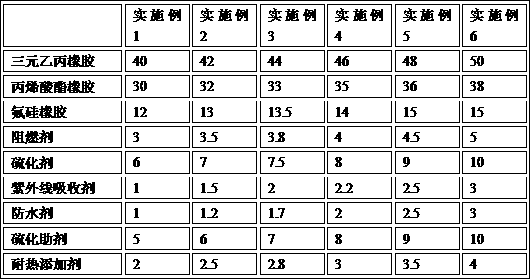

Embodiment 1

[0022] This embodiment provides a cable protective cover, which is made from the parts by weight of the raw materials described in Table 1. Wherein, the flame retardant is decabromodiphenylethane, the vulcanizing agent is N-nitroso diphenylamine, the ultraviolet absorber is ultraviolet absorber UV-O, and the waterproof agent is polyether binary alcohol, the vulcanization assistant is 2-mercaptobenzothiazole, and the heat-resistant additive is the brand of Dr. Lan, and the model is LBS-CeVR.

Embodiment 2

[0024] This embodiment provides a cable protective cover, which is made from the parts by weight of the raw materials described in Table 1. Wherein, the flame retardant is decabromodiphenyl ether, the vulcanizing agent is tetramethylthiuram disulfide, the ultraviolet absorber is ultraviolet absorber UV-P, the waterproofing agent is asphalt, and the asphalt For emulsified asphalt, the vulcanization aid is 2,2'-dithiodibenzothiazole, and the heat-resistant additive is the brand of Dr. Lan, and the model is LBS-CeVR.

Embodiment 3

[0026] This embodiment provides a cable protective cover, which is made from the parts by weight of the raw materials described in Table 1. Wherein, the flame retardant is decabromodiphenyl ether, the vulcanizing agent is N-nitroso diphenylamine, the ultraviolet absorber is ultraviolet absorber UV-P, and the waterproof agent is polyether glycol , the vulcanization aid is 2-mercaptobenzothiazole, and the heat-resistant additive is the brand of Dr. Lan, and the model is LBS-CeVR.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com