Motor train unit pump box unit device and manufacturing method thereof

A technology of a unit device and a manufacturing method, which is applied to pump devices, pump components, pump control and other directions, can solve the problems of easy freezing of water remaining in the piping system, no automatic emptying function, and high pressure of the piping system, so as to avoid failure to operate normally. Use, improve the working efficiency and stability of pump water, and prevent the effect of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

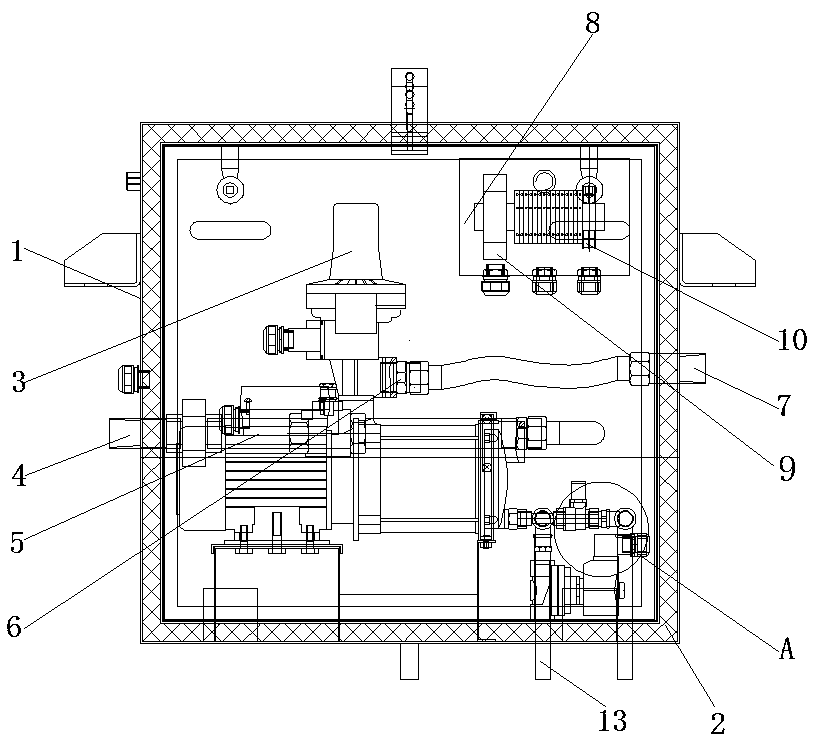

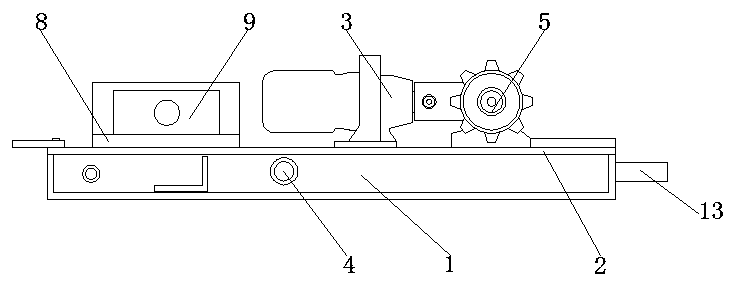

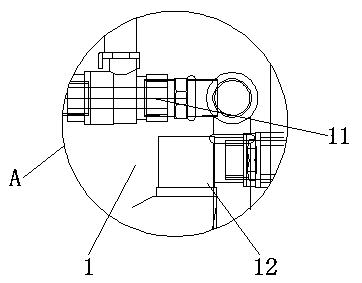

[0048] see Figure 1-3 , in an embodiment of the present invention, a pump box unit device for an EMU, including a box body 1 and a water pump 6 installed in the box body 1, a water inlet pipe 4 and a water outlet pipe 7 are installed on the box body 1, and the water inlet pipe 4 It is arranged on one side of the box body 1, and the other side of the box body 1 is provided with a water outlet pipe 7;

[0049] The inner wall of the box 1 is provided with an insulating material 2; through the use of the insulating material 2, the components inside the box 1 can be isolated and protected to prevent external low-temperature gas from entering the device, thereby reducing the operating time of the device. the possibility of malfunctions;

[0050] A pressure switch 3 is installed on the upper part of the water pump 6, and the pressure switch 3 is fixed on the box body 1 by screws; the pressure switch 3 makes the device have a pressure protection function, thereby improving the pumpi...

Embodiment 2

[0062] In an embodiment of the present invention, a manufacturing method based on the EMU pump box unit device described in Embodiment 1 includes the following steps:

[0063] Step 1. Paste insulation material 2 and aluminum foil inside the box 1 and the box door: the construction of the sealant should be carried out under the conditions of relative humidity 35-75% and room temperature 5°C-35°C;

[0064] Step 2. Assembling the pressure switch 3: Wrap the pipe magic rope evenly around the thread at the lower end of the pressure switch 3 for 8-12 turns, tighten the pressure switch 3 and the water pump 6, and the water outlet of the pressure switch 3 and the water inlet of the water pump 6 are on the same side;

[0065] Step 3. Assemble the drainage pipeline: evenly apply special railway sealant to the long end thread of the 3 / 8" tee and wind 3-5 turns of the pipeline magic rope, and fasten it with the water pump 6; preferably, the railway special The sealant is Loctite 577;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com