Method for cleaning of sand from toxic substances and cleaning composition

A harmful substance, clean technology, applied in the field of clean sand, can solve problems such as increasing process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

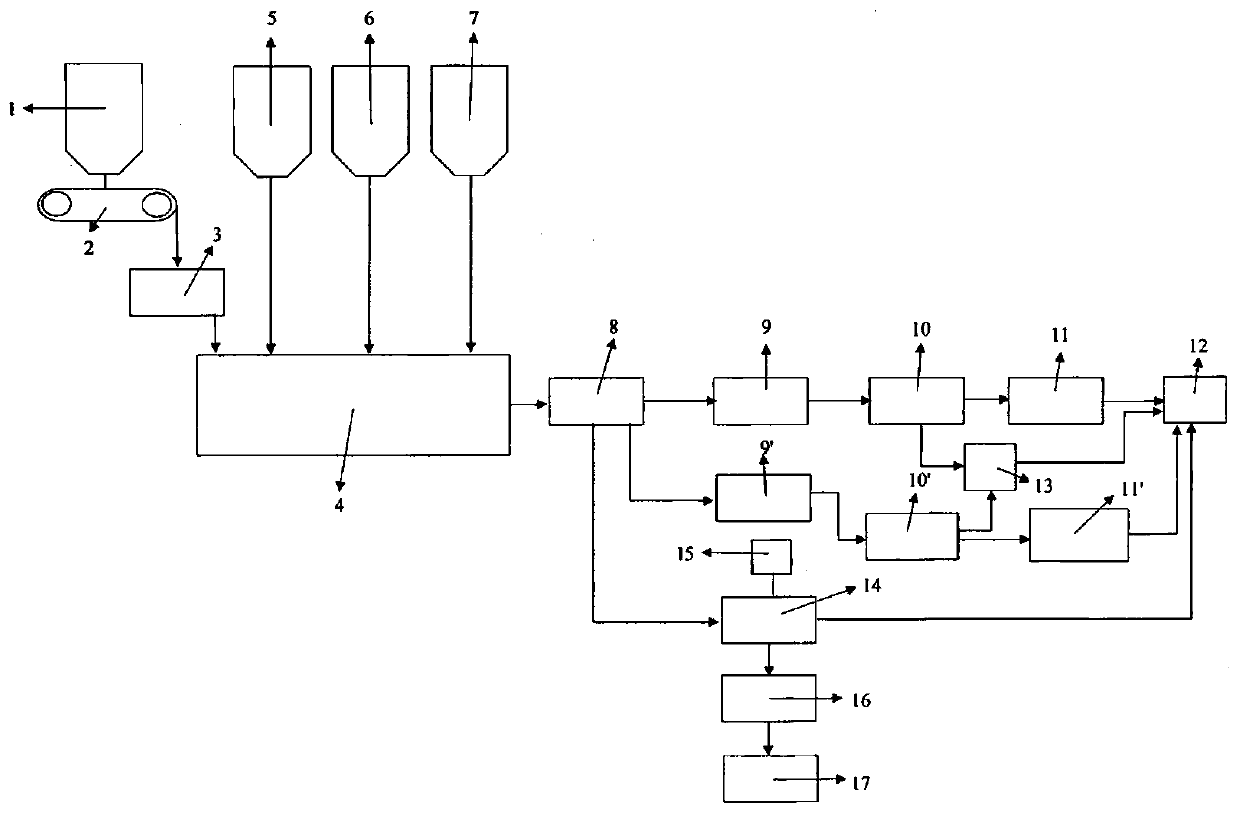

[0061] The sand is distributed into a receiving hopper 1 where a vibrating motor shakes off adhering material. The sand is conveyed by the conveyor belt 2 to the vibrating screen 3 with an opening size of 3 mm for dry screening. The material remaining on the screen is the paint and metal flakes produced during the blasting process and deposited as such. Products that pass through the sieve and have a size of up to 3mm are transferred to the rubbing machine 4 by a conveyor belt. Intensive cleaning / scrubbing of grit in thick mud at friction machine 4 by adding water from tank 4 (10:1-1:1 solid part: liquid part ratio): per ton of sand from tank / distributor 6 1 kg of calcium oxide and 2 liters of aqueous solution of disodium metasilicate, sodium carbonate, benzalkonium chloride and non-ionic surfactant per ton of sand from the tank / dispensing pump 7. The washed sludge is then gravity-fed to the dehydrator 8 where the sand is separated in two stages of sieves with meshes of 0.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com