Fish descaling roller and working method for adjusting the scraper angle of descaling structural parts by wireless remote control

A technology of wireless remote control and structural parts, applied in the direction of fish cleaning/descaling, etc., can solve the problems of low production efficiency, time-consuming and laborious, and single structural parts for descaling, and achieve a high degree of mechanical automation, convenient operation and control, and optimized The effect of descaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

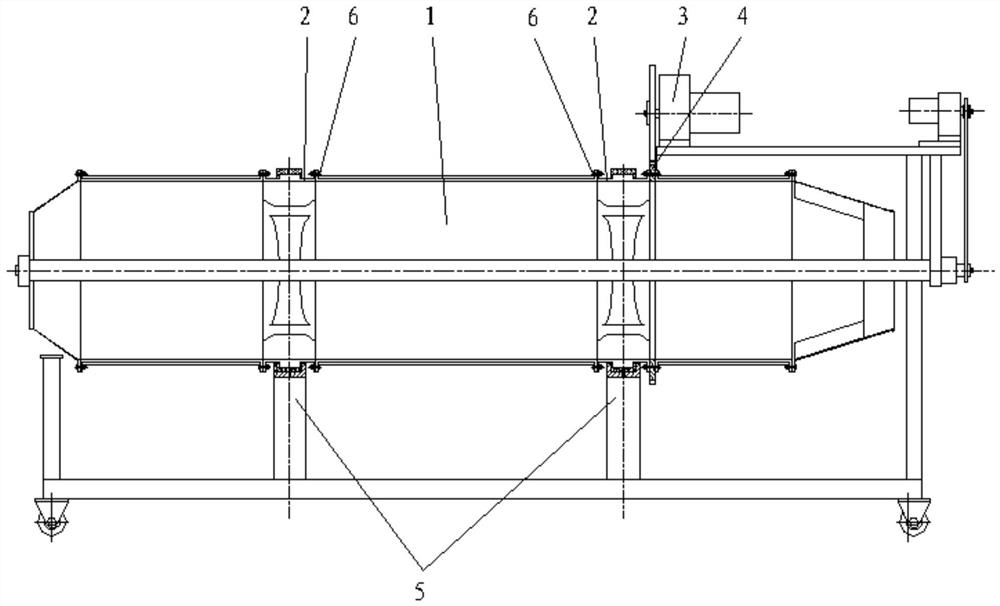

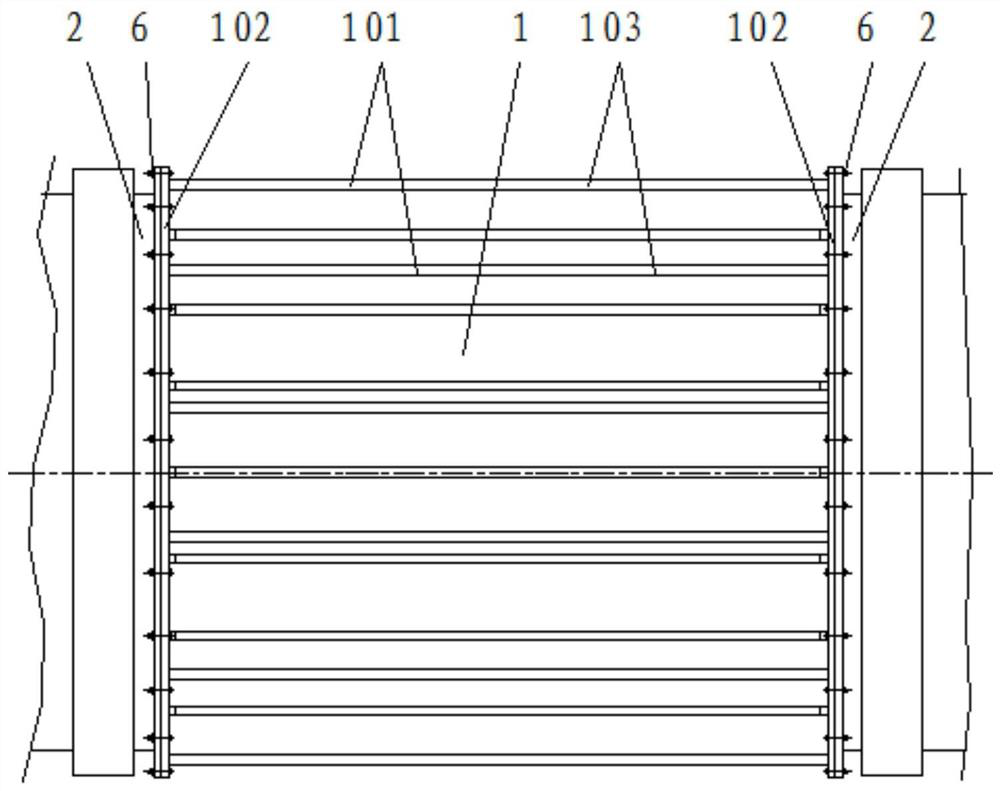

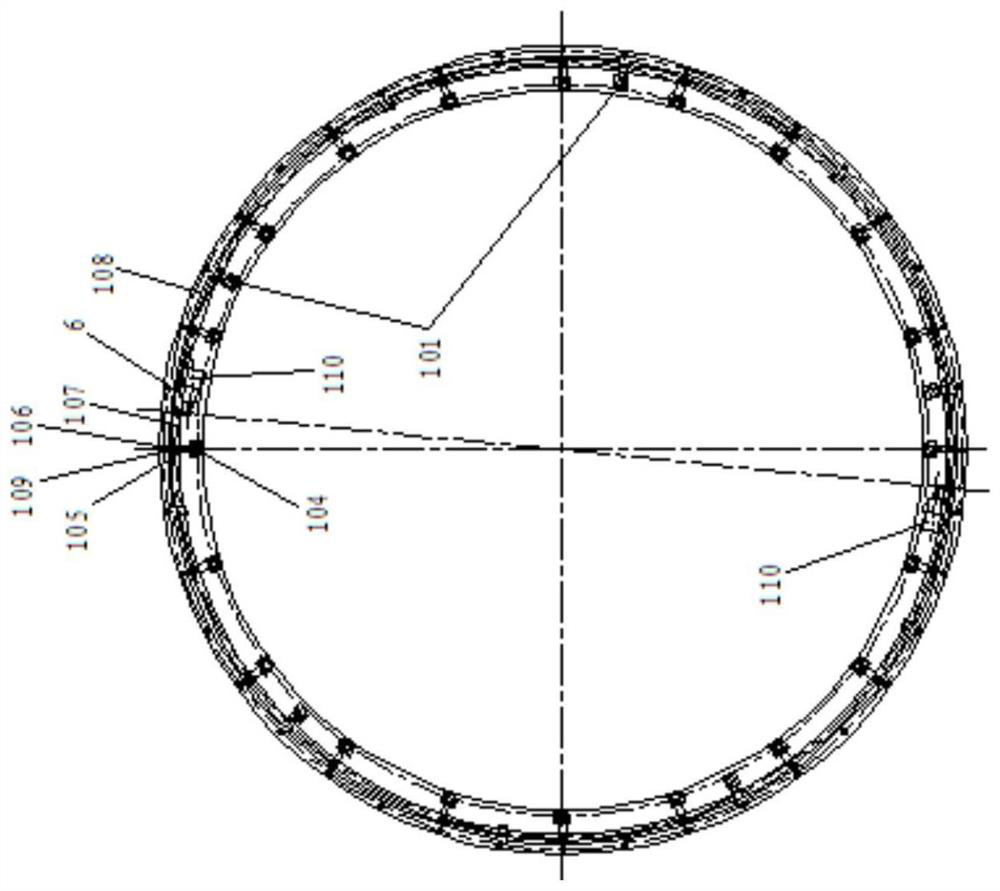

[0036] see Figure 1-Figure 12 , a fish descaling cylinder with wireless remote control to adjust the angle of the scraper of the descaling structural member, including the drum skeleton, the descaling scraper structural assembly 103, the anti-loosening stud 104, the end connecting rod 105 of the scraper structural assembly, and the scraper structural assembly Connecting pin 106 between the end connecting rod and the sliding ring, sliding ring 107, side pressure plate 108 of the ring, fasteners 109 for the pressure plate, high-energy battery-driven push-pull device 110, connectors between the connecting rod push-pull device and the sliding ring 111, and a hand-held wireless remote controller; the descaling scraper structure assembly 103 includes the long scraper 1031 of the descaling scraper structure assembly and the through-hole connector 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com