Method for preparing light-colored TDI (toluene diisocynate) based polyisocyanate composition curing agent with stable storage color number

A technology of toluene diisocyanate and polyisocyanate, which is applied in the field of polyisocyanate curing agent production, can solve the problems of making a decisive contribution and not pointing out the increase of color number, and achieve the effect of storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

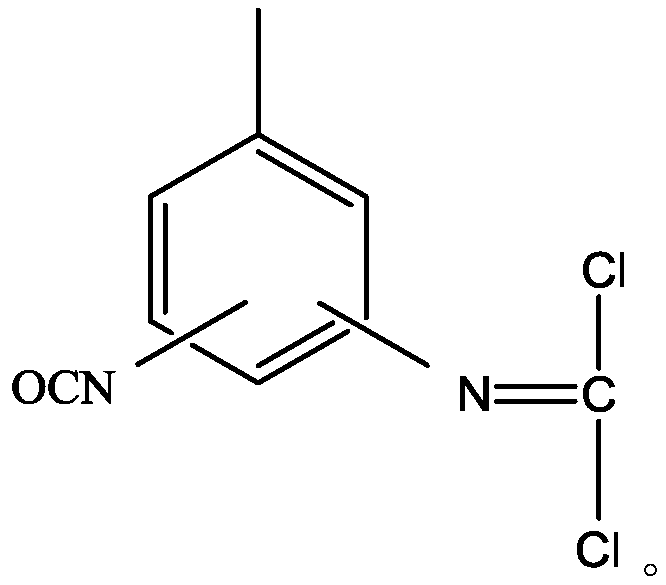

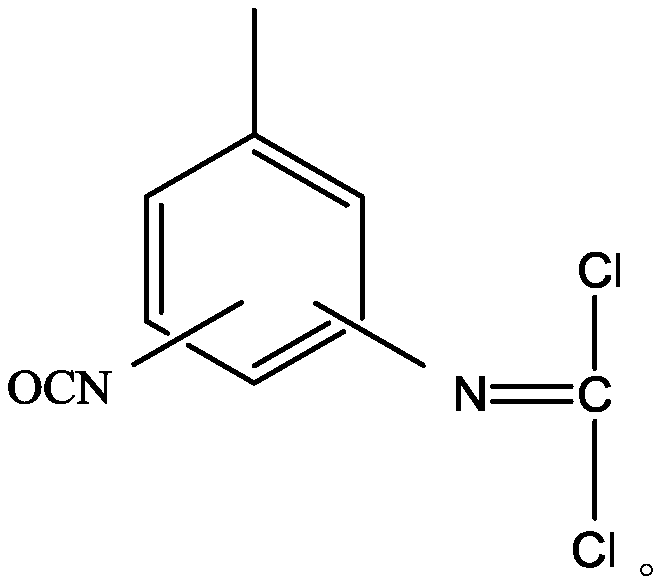

Image

Examples

Embodiment 1

[0045] First, rectify the toluene diisocyanate product whose proportion of 2,4-toluene diisocyanate is 80%. During the rectification process, the temperature of the tower kettle is controlled at 155°C, the absolute pressure of the rectification tower is 4kPa, and the pressure drop is 3kPa. The temperature of the top condenser is 20°C, the cryogenic temperature is -3°C, and the reflux ratio is 4:1. A toluene diisocyanate raw material with a dichloroimine content of 3 ppm was obtained.

[0046] Trimethylolpropane was added dropwise to 7 times the mass of the above purified toluene diisocyanate fraction. The material reaction temperature is controlled at 60° C., and the reaction time is 16 hours; after the reaction is completed, the aging operation is performed, and the aging temperature is controlled at 70° C., and the aging time is 1 hour to obtain a prepolymer reaction liquid. Excess toluene diisocyanate monomer is removed by short-range thin film evaporation, the separation...

Embodiment 2

[0048] First, rectify the toluene diisocyanate product whose proportion of 2,4-toluene diisocyanate is 80%. During the rectification process, the temperature of the tower kettle is controlled at 155°C, the absolute pressure of the rectification tower is 4kPa, and the pressure drop is 3kPa. The temperature of the top condenser is 20°C, the cryogenic temperature is -3°C, and the reflux ratio is 4:1. A toluene diisocyanate raw material with a dichloroimine content of 3 ppm was obtained.

[0049] Prepare a mixture of trimethylolpropane and propylene glycol with a mass ratio of 4:1. Then the above mixture was added dropwise to 7 times the mass of the above purified toluene diisocyanate component. The material reaction temperature is controlled at 60° C., and the reaction time is 16 hours; after the reaction is completed, the aging operation is performed, and the aging temperature is controlled at 70° C., and the aging time is 1 hour to obtain a prepolymer reaction liquid. Excess...

Embodiment 3

[0051] First, rectify the toluene diisocyanate product whose proportion of 2,4-toluene diisocyanate is 80%. During the rectification process, the temperature of the tower kettle is controlled at 165°C, the absolute pressure of the rectification tower is 2kPa, and the pressure drop is 3kPa. The temperature of the top condenser is 20°C, the cryogenic temperature is -3°C, and the reflux ratio is 5:1. A toluene diisocyanate raw material with a dichloroimine content of 1.8 ppm was obtained.

[0052] Prepare a mixture of trimethylolpropane and diethylene glycol, the mass ratio of the two is 3:1. Then the above mixture was added dropwise to 6 times the mass of the above purified toluene diisocyanate component. The reaction temperature of the material is controlled at 55° C., and the reaction time is 18 hours; after the reaction is completed, the aging operation is performed, and the aging temperature is controlled at 65° C., and the aging time is 2 hours to obtain a prepolymer reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com