A kind of ultra-high fluidity halogen-free flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, applied in the field of polypropylene composite materials, can solve the problems of decreased fluidity of polypropylene materials, easy swelling of polypropylene materials, and inapplicability to thin-walled products, etc., and achieves good anti-drip effect. , low cost, little effect on liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

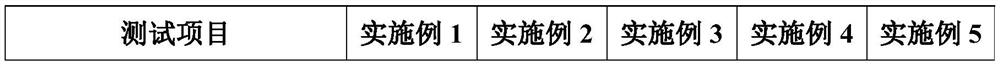

Examples

Embodiment 1

[0048] An ultra-high fluidity halogen-free flame-retardant polypropylene composite material, composed of the following components in mass percentage:

[0049] Polypropylene (BX3950, Korea SK Group): 50.4%;

[0050] P-N intumescent flame retardant (EPFR-110DL, Qingyuan Prosafefos Chemical Co., Ltd.): 30%;

[0051] Compatibilizer (EPDM-g-MAH): 3%;

[0052] Hyperdispersant (two-end polar silicone dispersant E 525, Degussa): 1%;

[0053] High aspect ratio filler (wollastonite powder with aspect ratio greater than 35): 10%;

[0054] Nano filler (nano silicon dioxide activated with silane coupling agent KH-560): 5%;

[0055] Lubricant (PE wax BN500, Bonney Chemical): 0.3%;

[0056] Antioxidant (antioxidant 1010:antioxidant 168=2:1, BASF): 0.3%.

[0057] The preparation method of the above-mentioned ultra-high fluidity halogen-free flame-retardant polypropylene composite material includes the following steps: selecting a twin-screw extruder with a second-stage side feed port, ...

Embodiment 2

[0060] The P-N intumescent flame retardant is EPFR-110DM from Qingyuan Prosafefos Chemical Co., Ltd., and the others are exactly the same as in Example 1.

Embodiment 3

[0062] What compatibilizer is selected is polypropylene grafted butyl acrylate, and others are exactly the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com