Water-based pull coating paint and preparation method thereof

A water-based paint, water-based technology, applied in the direction of polyurea/polyurethane paint, coating, etc., can solve the problems of insufficient paint, surface adhesion, rare and other problems, to eliminate fire hazards, reduce pollution, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] components parts by mass Classification Waterborne acrylic self-crosslinking emulsion 45.9 water-based resin Waterborne Polyurethane Dispersion 23 water-based resin 2-Amino-2-methyl-1-propanol 0.1 PH stabilizer 2-Octylisothiazolin-3-one 0.2 preservative Polyether siloxane copolymer 0.3 Water-based defoamer Waterborne polyurethane associative thickener 0.3 water-based thickener Waterborne modified silicone 0.5 water-based slip agent Water-based PE wax emulsion 5 Water-Based Wax Emulsion red color paste 25 Water-based color paste

[0030] The preparation method of embodiment one comprises the following steps:

[0031] a. Pour the water-based resin into the tank, and add the preservative under stirring;

[0032] b. Under stirring state, add the pH stabilizer;

[0033] c. In the state of stirring, add half of the water-based defoamer, the water-based slip agent, and the water-based wax ...

Embodiment 2

[0038] components parts by weight Classification Waterborne acrylic self-crosslinking emulsion 47.5 water-based resin Waterborne Polyurethane Dispersion 23.8 water-based resin 2-Amino-2-methyl-1-propanol 0.3 PH stabilizer 2-Octylisothiazolin-3-one 0.3 preservative Polyether siloxane copolymer 0.5 Water-based defoamer Waterborne polyurethane associative thickener 0.6 water-based thickener Waterborne modified silicone 0.8 water-based slip agent Water-based PE wax emulsion 5 Water-Based Wax Emulsion black color paste 22 Water-based color paste

[0039] The preparation method of embodiment two comprises the following steps:

[0040] a. Pour the water-based resin into the tank, and add the preservative under stirring;

[0041] b. Under stirring state, add the pH stabilizer;

[0042] c. In the state of stirring, add half of the water-based defoamer, the water-based slip agent, and the water-base...

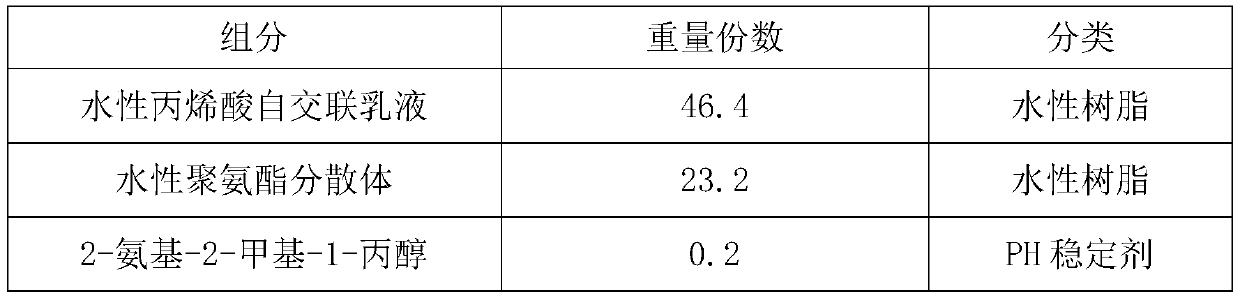

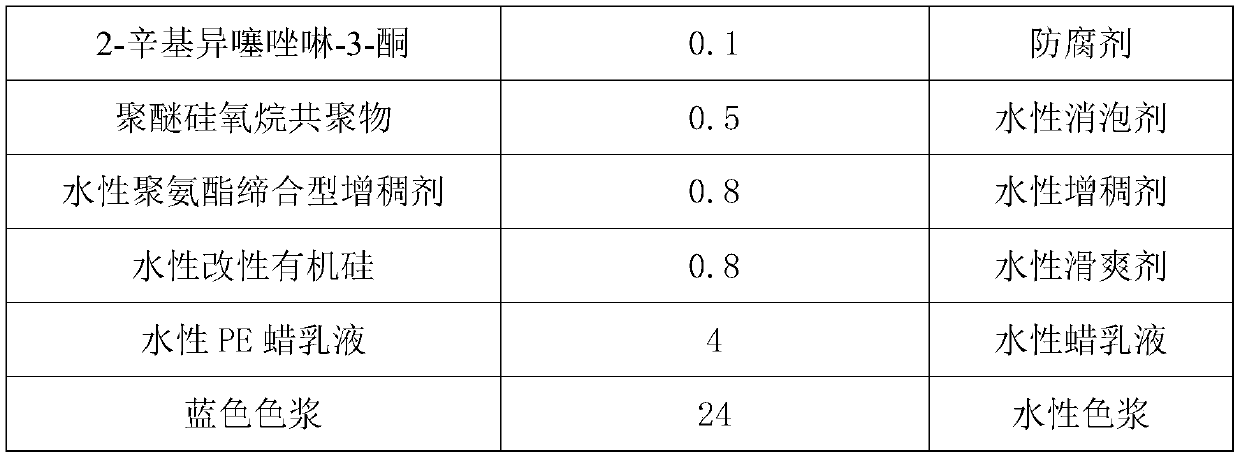

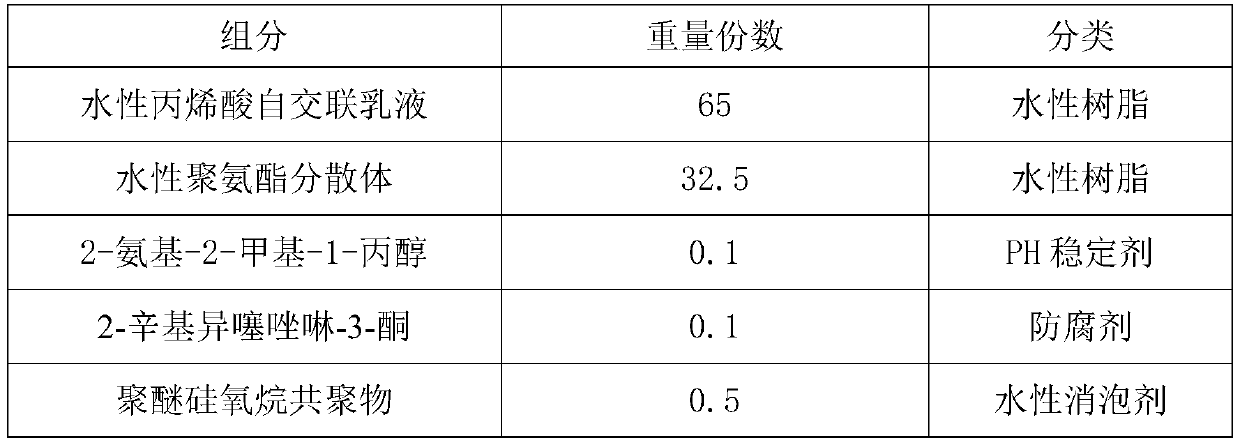

Embodiment 3

[0047]

[0048]

[0049] The preparation method of embodiment three comprises the following steps:

[0050] a. Pour the water-based resin into the tank, and add the preservative under stirring;

[0051] b. Under stirring state, add the pH stabilizer;

[0052] c. In the state of stirring, add half of the water-based defoamer, the water-based slip agent, and the water-based wax emulsion, and wait to stir fully;

[0053] d. In the state of stirring, add the water-based color paste and the water-based thickener, and wait until fully stirred;

[0054] e. In the state of stirring, add the remaining half of the water-based defoamer, and wait until it is fully stirred.

[0055] The pH value of the water-based paint is 7.5-8.5, the viscosity is 10000-15000cps / 25°C, and the fineness is less than 10um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com