A rare earth-doped hydroxyapatite/titanium oxide composite fluorescent coating material and its preparation method and application

A technology of hydroxyapatite and rare earth doping, which is applied in luminescent materials, chemical instruments and methods, and pharmaceutical formulations, and can solve the problems of large amount of rare earth doping, high cost, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) At room temperature, 11.81 g of Ca(NO 3 ) 2 ·4H 2 O, 0.13g Sm (NO 3 ) 3 and 0.5g Na 3 C 6 H 5 O 7 ·2H 2 O was mixed and dissolved in 50 mL of deionized water, adjusted to pH=9, and mixed solution A was obtained; 4 ) 2 HPO 4 Dissolve in deionized water to prepare a diammonium hydrogen phosphate solution, slowly drop the diammonium hydrogen phosphate solution into the above mixed solution, continue to stir vigorously for 4 hours, and adjust pH=9 with ammonia water to obtain translucent rare earth doped hydroxyapatite sol;

[0038] (2) The rare earth-doped hydroxyapatite sol obtained in step (1) was evenly coated on the quartz glass sheet, and then placed in a constant temperature drying oven at 60°C for 2 hours, and then calcined at 800°C for 3 hours and then followed by drying. The furnace is cooled to room temperature to obtain rare earth-doped hydroxyapatite fluorescent coating material, denoted as Sm 0.01 HA.

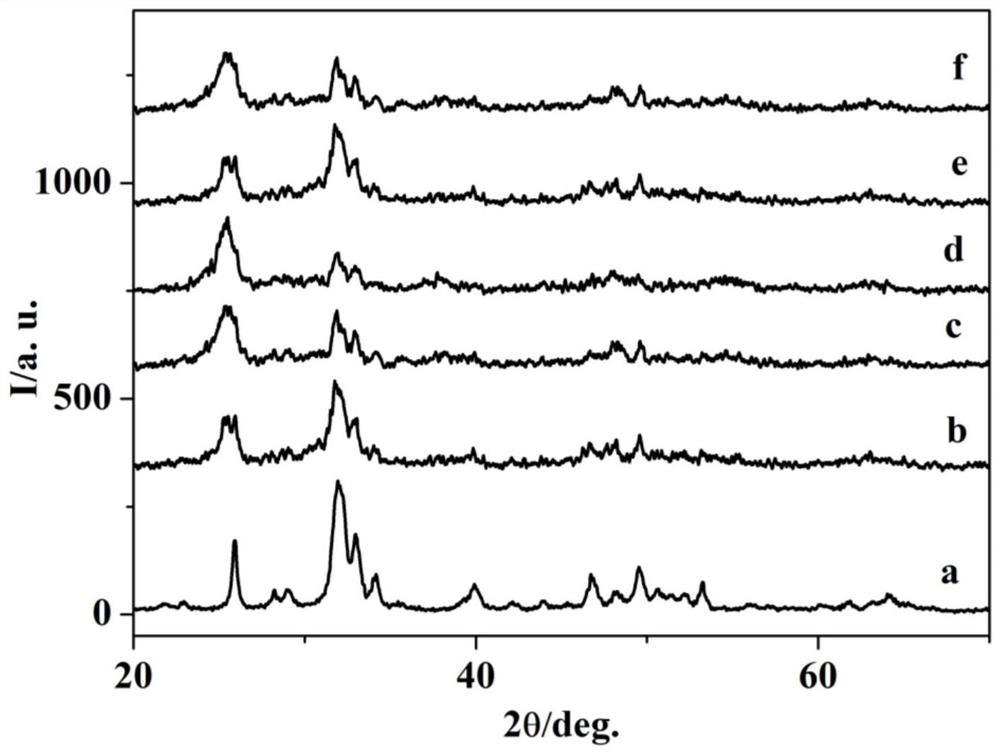

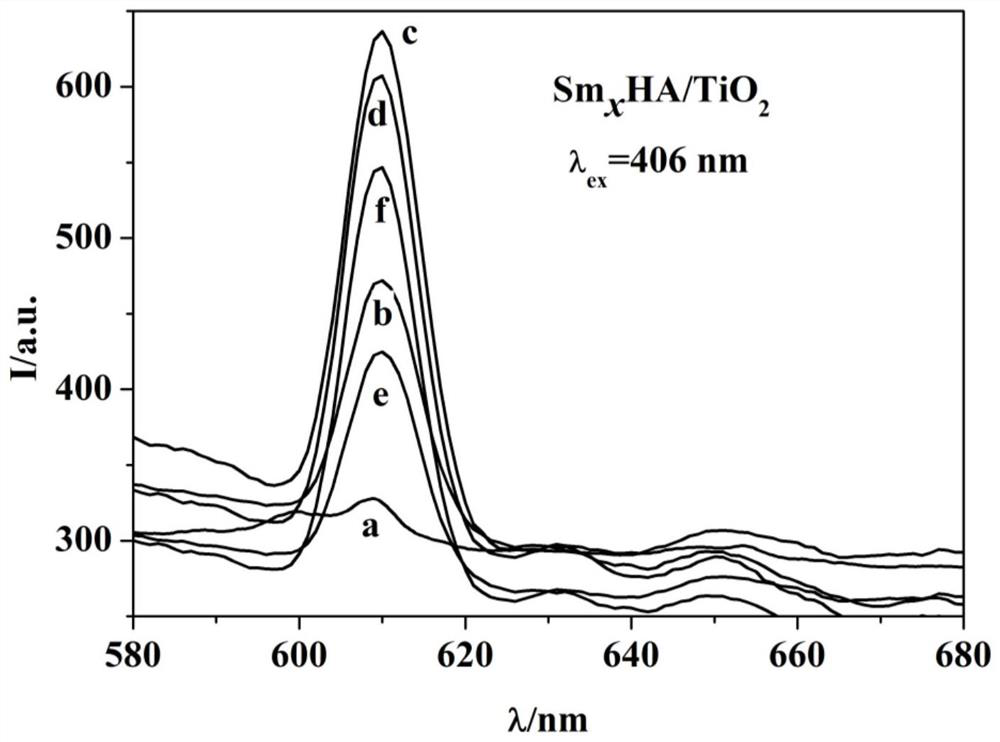

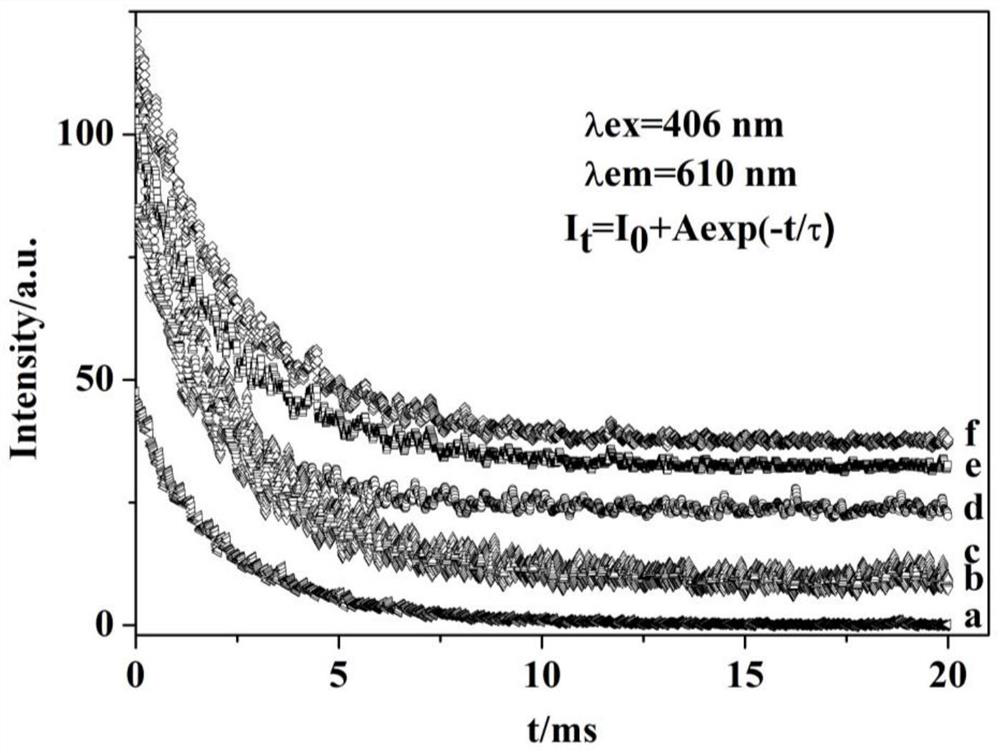

[0039] The composition and structure of...

Embodiment 2

[0041] (1) At room temperature, 11.81 g of Ca(NO 3 )2 ·4H 2 O, 0.13g Sm (NO 3 ) 3 and 0.5g Na 3 C 6 H 5 O 7 ·2H 2 O was mixed and dissolved in 50 mL of deionized water, adjusted to pH=9, to obtain a mixed solution; 3.69 g (NH 4 ) 2 HPO 4 Dissolve in deionized water to prepare a diammonium hydrogen phosphate solution, slowly drop the diammonium hydrogen phosphate solution into the above mixed solution, continue to vigorously stir for 4 hours, and adjust pH=9 with ammonia water to obtain translucent rare earth-doped hydroxyapatite Sol, denoted as sol A;

[0042] (2) At room temperature, 17 mL of butyl titanate (C 16 H 36 O 4 Ti) and 83 mL of absolute ethanol (CH 3 CH 2 OH) mixed evenly, and continued stirring for 2h to obtain a light yellow transparent titanium oxide sol, denoted as sol B;

[0043] (3) According to the volume ratio of sol A:sol B=1:1, measure 30 mL of each of sol A and sol B, then mix, stir for 2 hours and then let stand to obtain a rare earth-do...

Embodiment 3

[0047] (1) At room temperature, 11.81 g of Ca(NO 3 ) 2 ·4H 2 O, 0.39g Sm (NO 3 ) 3 and 0.5g Na 3 C 6 H 5 O 7 ·2H 2 O was mixed and dissolved in 50 mL of deionized water, adjusted to pH=9, to obtain a mixed solution; 3.69 g (NH 4 ) 2 HPO 4 Dissolve in deionized water to prepare a diammonium hydrogen phosphate solution, slowly drop the diammonium hydrogen phosphate solution into the above mixed solution, continue to stir vigorously for 4 hours, and adjust pH=9 with ammonia water to obtain translucent rare earth doped hydroxyapatite Stone sol, denoted as sol A;

[0048] (2) At room temperature, 17 mL of butyl titanate (C 16 H 36 O 4 Ti) and 83 mL of absolute ethanol (CH 3 CH 2 OH) and mix evenly, and continue to stir for 2 h to obtain a light yellow transparent titanium oxide sol, which is denoted as sol B;.

[0049] (3) According to the volume ratio of sol A:sol B=1:1, measure 30 mL of each of sol A and sol B, then mix, stir for 2 hours and then let stand to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com