Environment-friendly high-strength sludge fence filter cloth

A high-strength, silt technology, used in fabrics, multi-strand fabrics, textiles, etc., can solve the problems of increased production costs and unreasonable production processes, and achieve the effects of improving strength, low density and reducing UV damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

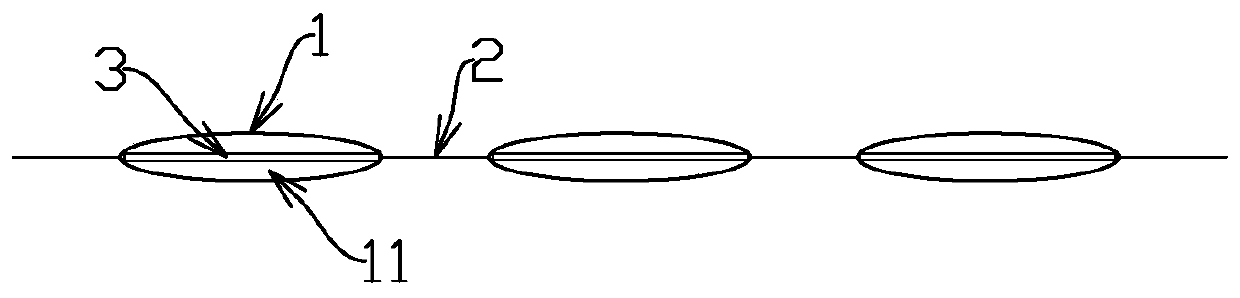

[0022] to combine figure 1 , to describe this embodiment in detail. An environmentally friendly high-strength silt fence filter cloth involved in this embodiment is prepared by the following steps: step A preparation of warp and weft yarns, step B warping, step C weaving, step D threading, and step E threading the cloth Geotextile for visual inspection.

[0023] In the preparation of warp and weft yarns in step A, a wire drawing machine is used to prepare polypropylene filaments with rectangular and circular cross-sections at a draw ratio of 6.8. Warp yarns include upper layer warp yarns and lower layer warp yarns, the cross section is rectangular, and the cross section of weft yarns is circular. The width of the upper warp yarn and the lower warp yarn is 100 silk, and the thickness is 10-20 silk, preferably 15 silk in the present embodiment; the diameter of the weft yarn is 35 silk.

[0024] In step B warping, segmental warping is adopted, and the upper warp yarns are warp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com