Vanadium sodium phosphate cathode material doped with ruthenium and wrapped in carbon and preparation method of cathode material

A technology of carbon-coated sodium vanadium phosphate and positive electrode materials, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problem of limiting charge and discharge capabilities, affecting high specific capacity, electronic conductivity and low ion migration rate, etc. problem, to achieve the effect of improving intrinsic electronic conductivity, simplifying the reaction process, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

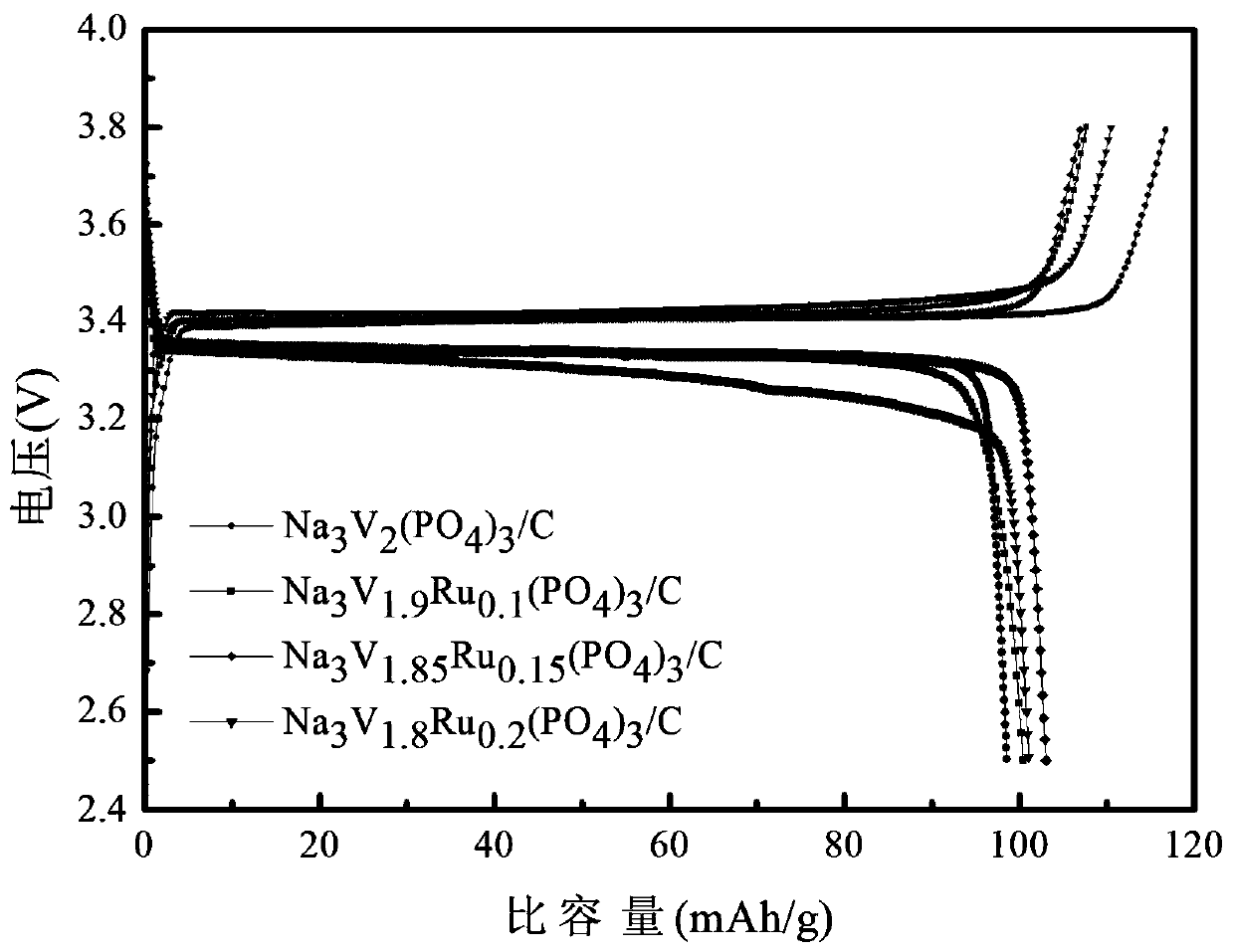

Embodiment 1

[0029] The present embodiment prepares sodium vanadium phosphate cathode material Na according to the following steps 3 V 2 (PO 4 ) 3 / C(x=0):

[0030] (1) According to the molar ratio of Na:V:P:C=3:2:3:2, weigh Na 2 CO 3 0.0075mol, NH 4 VO 3 0.01mol, NH 4 h 2 PO 4 0.015mol, citric acid 0.01mol;

[0031] (2) NH 4 VO 3 Mix with 0.01mol oxalic acid, add 50mL deionized water to dissolve, stir and heat in a water bath at 60°C until it is completely dissolved, and then add Na 2 CO 3 and NH 4 h 2 PO 4 Miscible in deionized water and dropwise into the above solution, stirred and heated in a water bath at 90°C for 40 minutes to form a mixed solution; then miscible citric acid and 10mL PEG-400 in deionized water, then added the above mixed solution , continue stirring and heating for 3.5h to form a gel; dry the gel in vacuum and then grind it for a period of time to obtain a mixed powder;

[0032] (3) Heat the mixed powder at 2°C / min to 350°C for 4 hours in a tube ...

Embodiment 2

[0037] The present embodiment prepares sodium vanadium phosphate cathode material Na according to the following steps 3 V 1.9 Ru 0.1 (PO 4 ) 3 / C(x=0.1):

[0038] (1) According to the molar ratio of Na:V:Ru:P:C=3:1.9:0.1:3:2, weigh Na 2 CO 3 0.0075mol, NH 4 VO 3 0.0095, RuCl 3 0.0005mol, NH 4 h 2 PO 4 0.015mol, citric acid 0.01mol;

[0039] (2) NH 4 VO 3Mix with 0.01mol oxalic acid, add 50mL deionized water to dissolve, stir and heat in a water bath at 60°C until it is completely dissolved, and then add Na 2 CO 3 and NH 4 h 2 PO 4 Miscible in deionized water and dropwise added to the above solution, stirred and heated in a water bath at 90°C for 40 minutes to form a mixed solution; then RuCl 3 , citric acid and 10mL PEG-400 were miscible in deionized water, added to the above mixture, continued to stir and heat for 3.5h to form a gel; vacuum dried the gel and then ground it for a period of time to obtain a mixed powder;

[0040] (3) Heat the mixed powder ...

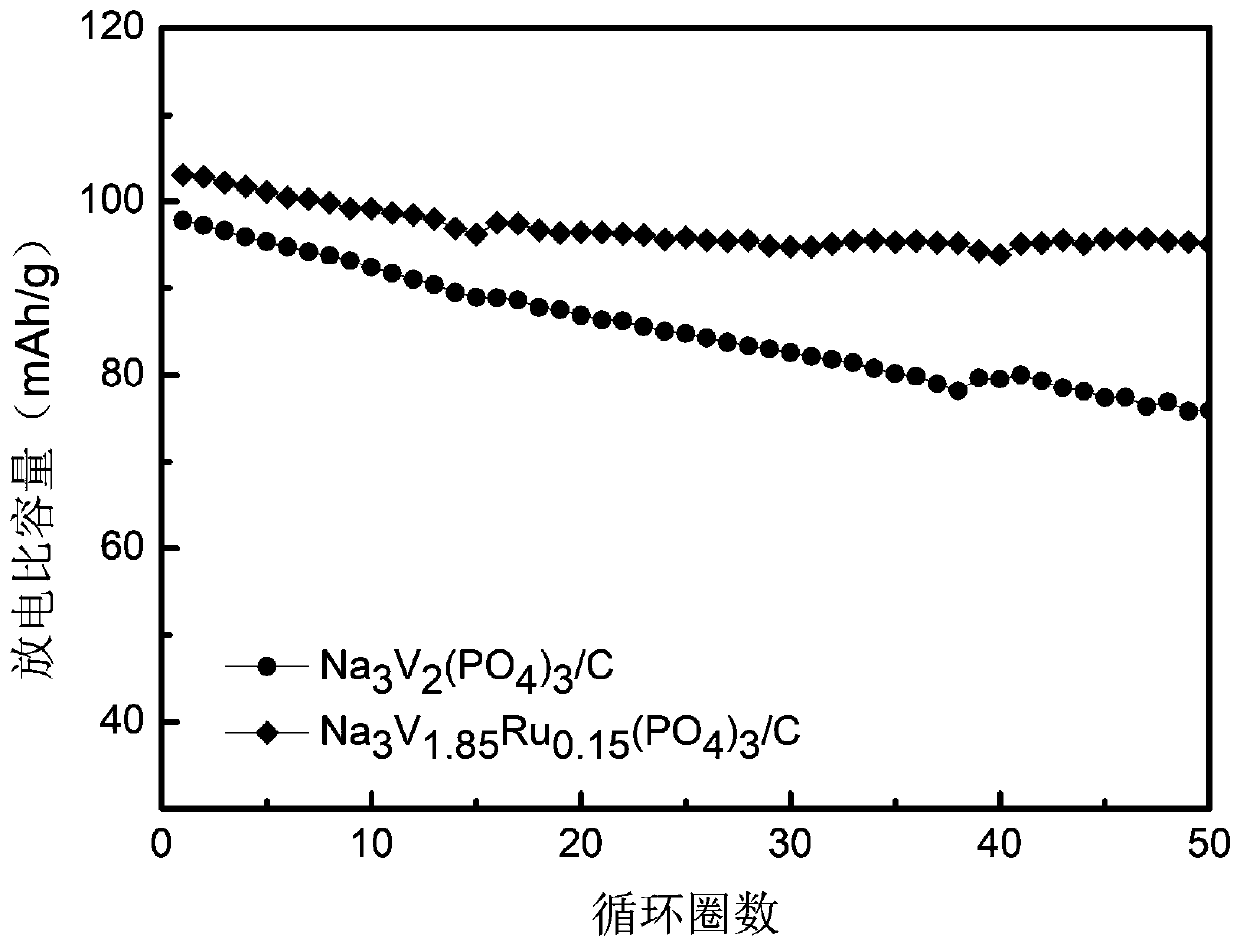

Embodiment 3

[0045] The present embodiment prepares sodium vanadium phosphate cathode material Na according to the following steps 3 V 1.85 Ru 0.15 (PO 4 ) 3 / C(x=0.15):

[0046] (1) According to the molar ratio of Na:V:Ru:P:C=3:1.85:0.15:3:2, weigh Na 2 CO 3 0.0075mol, NH 4 VO 3 0.00925mol, RuCl 3 0.00075mol, NH 4 h 2 PO 4 0.015mol, citric acid 0.01mol;

[0047] (2) NH 4 VO 3 Mix with 0.01mol oxalic acid, add 50mL deionized water to dissolve, stir and heat in a water bath at 60°C until it is completely dissolved, and then add Na 2 CO 3 and NH 4 h 2 PO 4 Miscible in deionized water and dropwise added to the above solution, stirred and heated in a water bath at 90°C for 40 minutes to form a mixed solution; then RuCl 3 , citric acid and 10mL PEG-400 were miscible in deionized water, added to the above mixture, continued to stir and heat for 3.5h to form a gel; vacuum dried the gel and then ground it for a period of time to obtain a mixed powder;

[0048] (3) Heat the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com