Lithium metal cathode, preparation method thereof, and preparation method of all-solid-state battery

A lithium metal negative electrode and metal lithium technology, applied in secondary batteries, battery electrodes, electrode carriers/collectors, etc., to achieve the effects of increasing energy density, reducing local current density, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

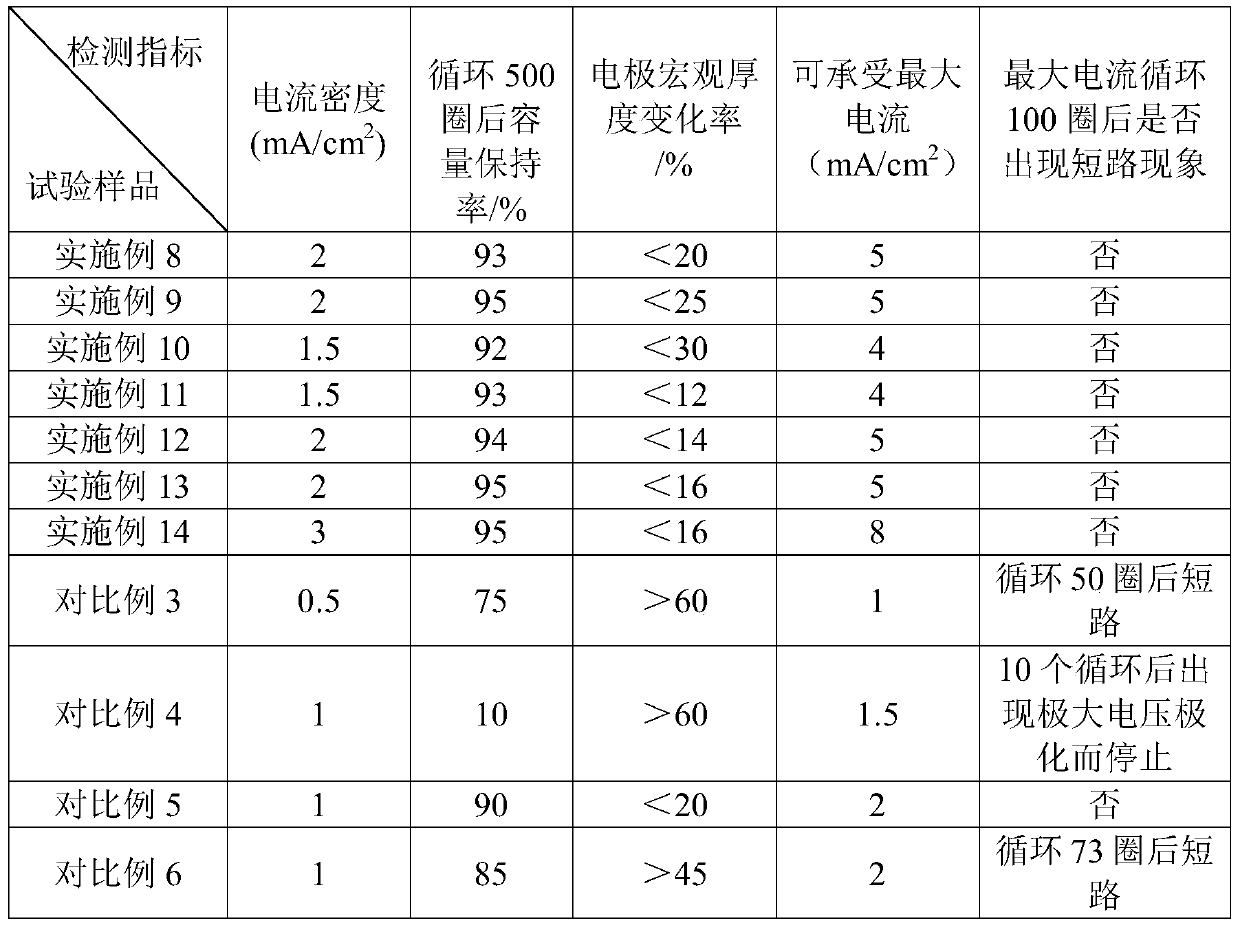

Examples

Embodiment 1

[0073] Example 1: Lithium metal negative electrode, prepared by the following steps:

[0074] Step 1, uniformly mix the polymer solid electrolyte polyoxyethylene, 20g of acetonitrile, 1g of polyethylene dispersant, and 2g of SBR binder to obtain the first mixture;

[0075] Step 2, select granular lithium powder (equivalent volume equivalent diameter is 30 μm), add 120g granular lithium powder (the volume ratio of lithium powder to polymer solid electrolyte polyoxyethylene is 5) to step 1, and stir in vacuum evenly to obtain the first Two mixtures;

[0076] In step 3, the second mixture is evenly coated on the copper foil, and dried in vacuum to obtain a lithium metal negative electrode.

Embodiment 2

[0077] Example 2: Lithium metal negative electrode, the difference from Example 1 is that the steps of the preparation process are as follows:

[0078] In step 1, the polymer solid electrolyte (polyvinylene carbonate), 30g of acetonitrile, 2g of polyethylene dispersant, and 10g of SBR binder are uniformly mixed to obtain the first mixture;

[0079] Step 2, select granular lithium powder (equal volume equivalent diameter 10 μm), add 160g granular lithium powder (volume ratio of lithium powder and polymer solid electrolyte (polyvinylene carbonate) to the first mixture obtained in step 1 is 7), vacuum stirring to obtain the second mixture;

[0080] Step 3, coating the second mixture obtained in Step 2 on a copper foil, and drying in a vacuum to obtain a lithium metal negative electrode.

Embodiment 3

[0081]Example 3: lithium metal negative electrode, the difference from Example 1 is that the steps of the preparation process are as follows:

[0082] Step 1, the solid electrolyte A formed by polysiloxane and LAGP powder, the solvent composed of 25g toluene and 15g n-hexane, 3g polyethylene dispersant, and 5g SBR binder are uniformly mixed to obtain the first mixture;

[0083] Step 2, select granular lithium powder (equivalent volume diameter 1 μm), add 200g granular lithium powder (solid electrolyte A formed by lithium powder and polysiloxane / LAGP powder) to the first mixture obtained in step 1 The volume ratio is 10), and the vacuum stirring is evenly obtained to obtain the second mixture;

[0084] Step 3, coating the second mixture obtained in Step 2 on a copper foil, and drying in a vacuum to obtain a lithium metal negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com