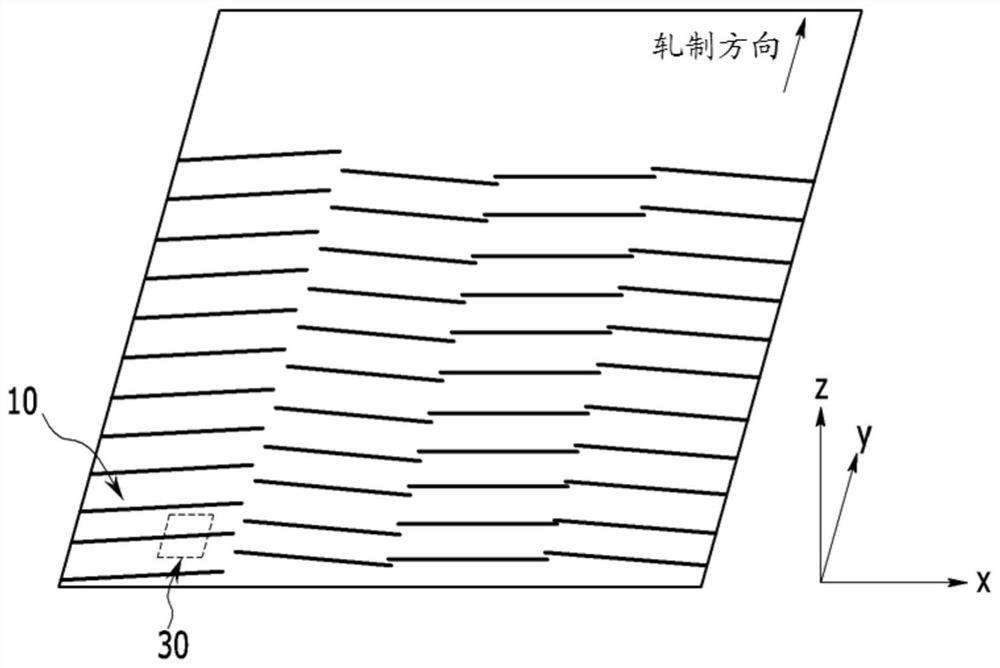

Grain-oriented electrical steel sheet and its magnetic domain refinement method

A technology of oriented electrical steel sheet and magnetic domain refinement, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of damaged roughness and difficulty in removing bulges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

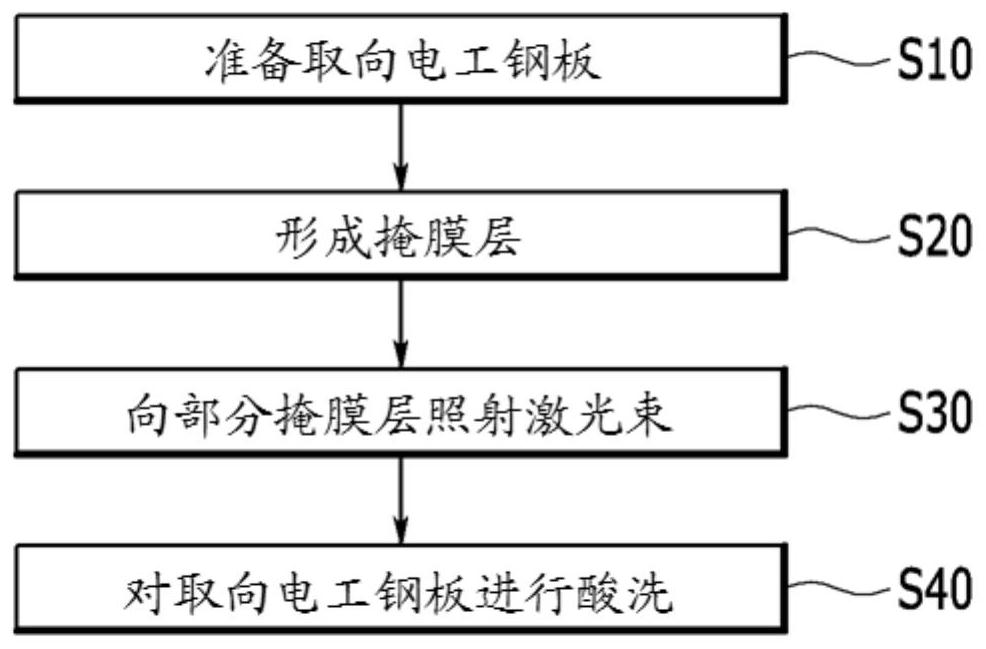

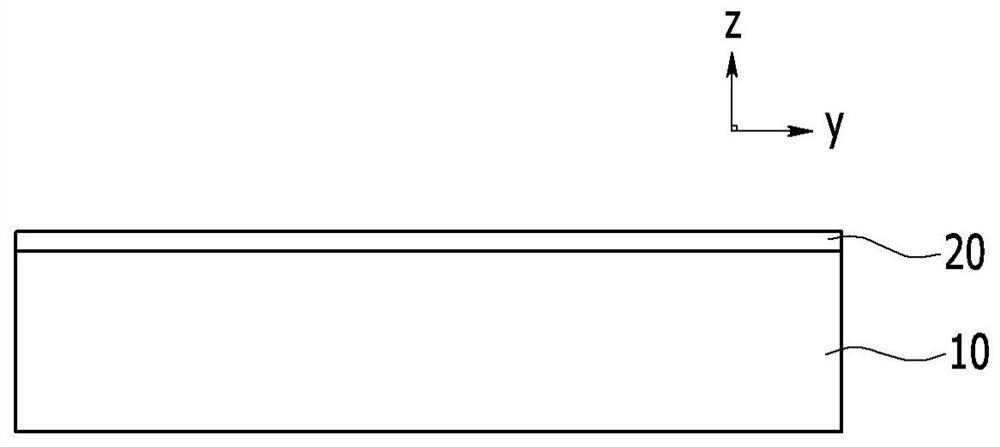

[0070] Embodiment 1: Forming the prefabricated trench

[0071] A cold-rolled grain-oriented electrical steel sheet having a thickness of 0.20 mm was prepared. The surface of the electrical steel sheet was coated with a coating liquid mixed with MgO and water at a weight ratio of 1:1, and dried at 100° C. to form a mask layer with a thickness of 5 μm. The single-fiber laser light having the output collated in Table 1 below was irradiated at the irradiation speed collated in Table 1 below. At this time, the moving speed of the steel plate is also sorted out in Table 1 below. In addition, the focus positions of the laser beams and the intervals on the surface of the grain-oriented electrical steel sheet are organized in Table 1 below. The width and depth of the pre-grooves formed by laser irradiation are collated in Table 1 below. The width of the prefabricated groove refers to the width on the surface of the steel plate.

[0072] [Table 1]

[0073]

Embodiment 2

[0074] Example 2: Forming a trench

[0075] The steel plates formed with the pregrooves in Inventive Examples 1 to 7 were pickled with hydrochloric acid having the concentration sorted in Table 2 below, and the pickling time was sorted out in Table 2 below. The upper width W of the final trench a Keep constant at 120 μm. The depth D of the groove, the middle width W at 1 / 2 depth b , the ratio of the upper width to the middle width (W b / W a ), the roughness of the groove part is arranged in the following table 2. The roughness adopts JIS97 standard.

[0076] [Table 2]

[0077]

Embodiment 3

[0084] Embodiment 3: Form insulating film layer and measure magnetism, duty cycle

[0085] An insulating coating liquid containing colloidal silica and metal phosphate was coated on the grain-oriented electrical steel sheets in which grooves were formed in Inventive Examples 8 to 17 and Comparative Examples 1 and 2, and heat-treated to form grooves on the surface of the steel sheets. Insulating film layer, and after measuring the magnetic properties and duty cycle, they are arranged in Table 4 below.

[0086] Regarding the iron loss improvement rate, the iron loss (W 1 ) and iron loss after laser irradiation to form grooves (W 2 ) after measurement, by (W 1 -W 2 ) / W 1 To calculate the iron loss improvement rate.

[0087] The duty ratio was measured by stacking 14 samples of 60 mm×300 mm and calculating the iron area relative to the total area.

[0088] [Table 4]

[0089] Classification Iron loss improvement rate (%) Duty cycle (%) Invention Example 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com