Hollow tubular water processing membrane element ultrasonic wave descaling device, and method thereof

A water treatment membrane and ultrasonic technology, applied in the direction of osmosis/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of inconvenient maintenance and replacement, numerous devices, and fixed installation positions, etc., to improve descaling and cleaning effect, reduction of corrosion, and reduction of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

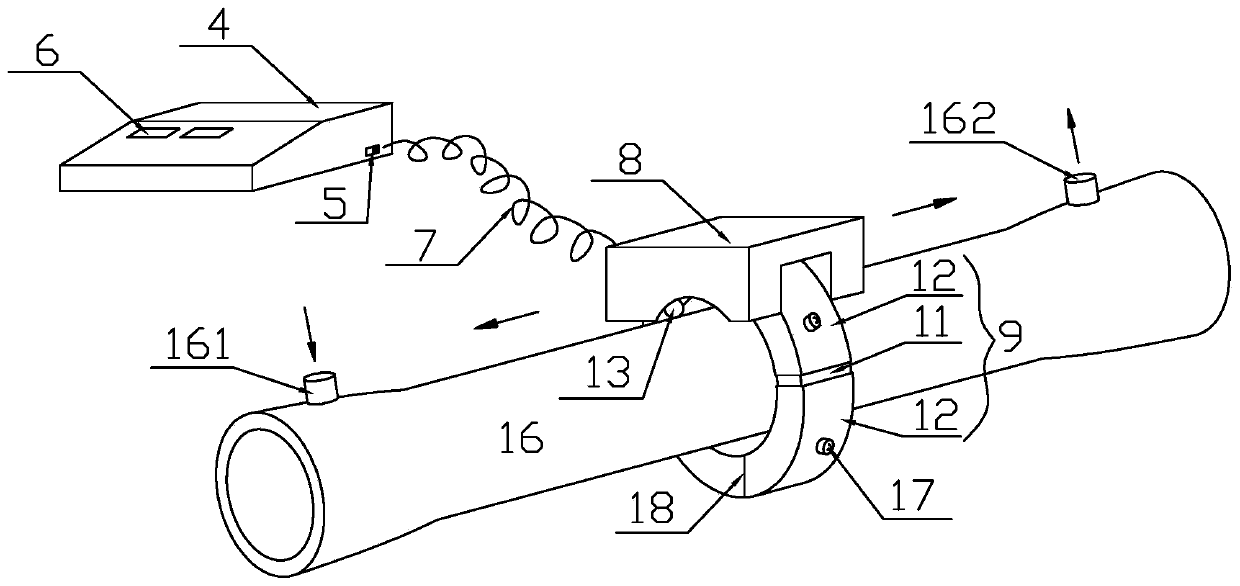

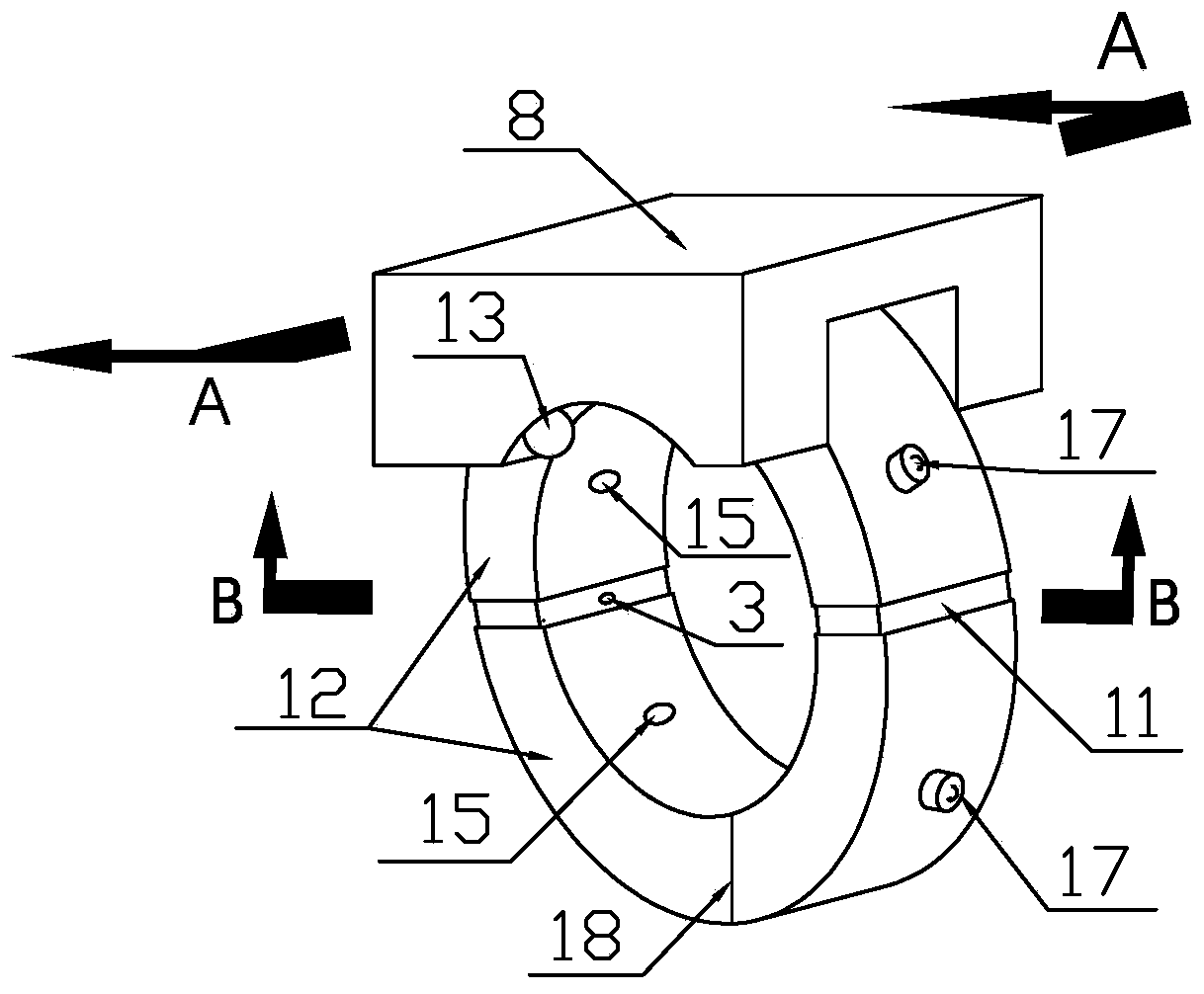

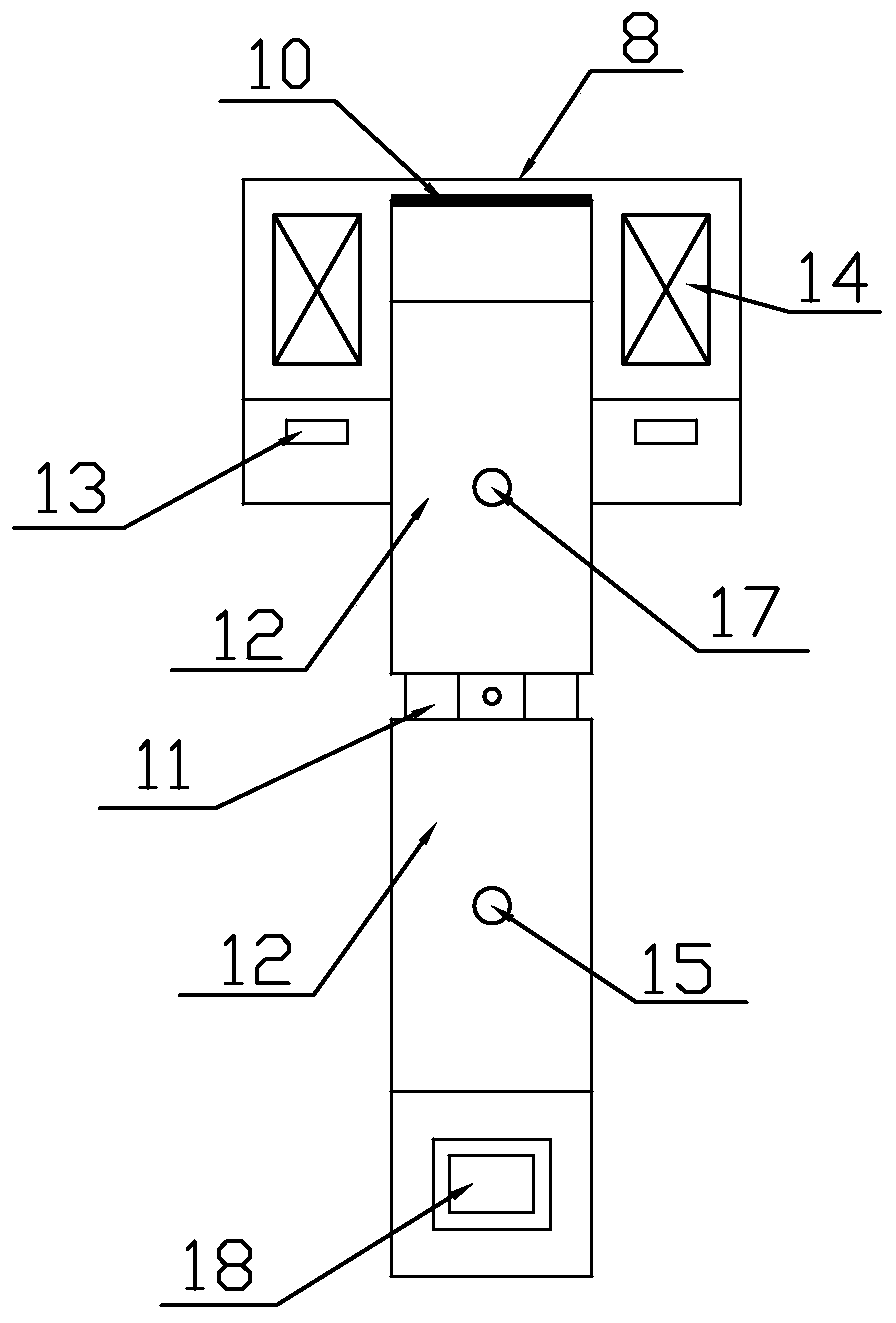

[0040] Implementation mode one: if Figure 1-4 As shown, the hollow tubular water treatment membrane element ultrasonic descaling device includes an ultrasonic generating unit and a control unit, wherein the ultrasonic generating unit includes an ultrasonic transducer 1, a horn 2 and a high-frequency marble contact 3; the control unit includes a shell Body 4, power switch 5 and operating parameter regulator 6, the operating parameter regulator 6 is arranged in the housing 4, the operating parameter regulator 6 is connected to the ultrasonic transducer 1 of the ultrasonic generating unit through a retractable power supply signal line 7, It is characterized in that it also includes a walking servo unit, the walking servo unit includes a box body 8 and two semicircular clasps 9, the upper ends of the two semicircular clasps 9 are connected by a hinge shaft 10, and the hinge shaft 10 is parallel to On the axis line of the semicircular embracing ring 9, the lower ends of the two se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com