Preparation method and applications for precious metal doped PVDF nanofiber composite film

A technology of nanofibers and composite membranes, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of limiting residents' personal protection, difficult and efficient interception, low air filtration pressure resistance, etc., and achieve a significant sterilization effect , the effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

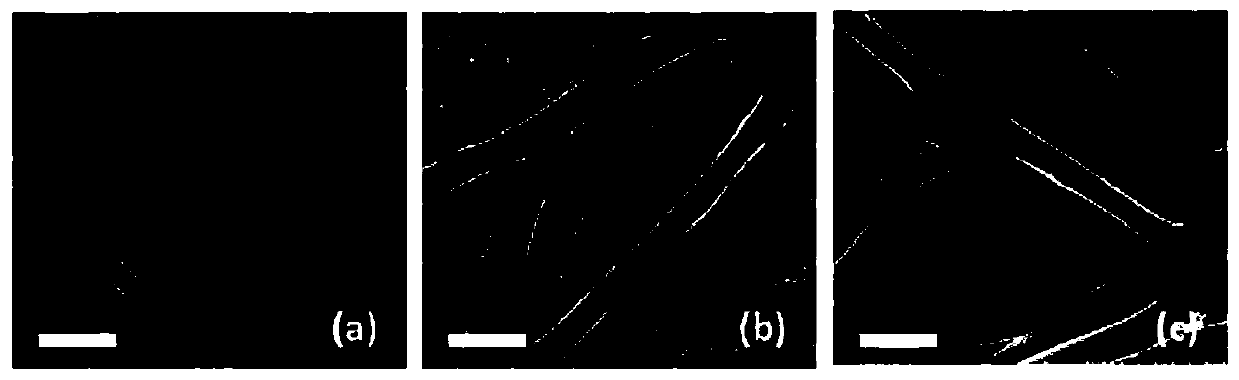

Image

Examples

Embodiment 1

[0030] Ag + The preparation method of the PVDF nanofiber composite membrane of ion doping, comprises the following steps,

[0031] (1) Preparation of nanofiber composite membrane substrate: Deposit silver metal with a thickness of 150nm on the ultra-thin and high-transmittance non-woven fabric by magnetron sputtering; enhancing the conductivity of the substrate can improve the final filter membrane Uniformity of thickness. A filter membrane that is too thick will greatly enhance the value of the pressure difference, while a filter membrane that is too thin will seriously affect the improvement of filtration performance. Therefore, this step is a relatively critical step, and the non-uniform filtration membrane thickness will seriously restrict the improvement of the filtration performance of later products;

[0032] (2) Preparation of PVDF precursor solution: After uniformly mixing 7mL N,N-dimethylformamide and 3mL acetone, add 1.6g PVDF powder, after ultrasonic treatment fo...

Embodiment 2

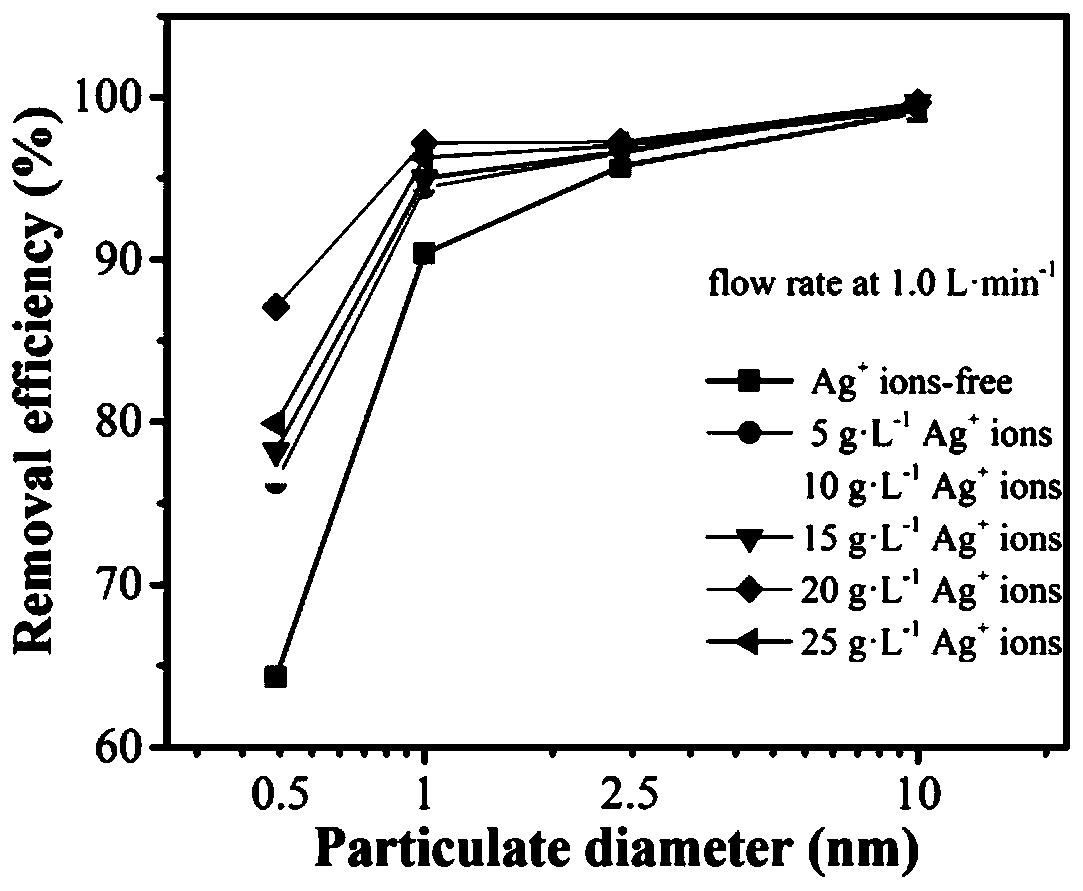

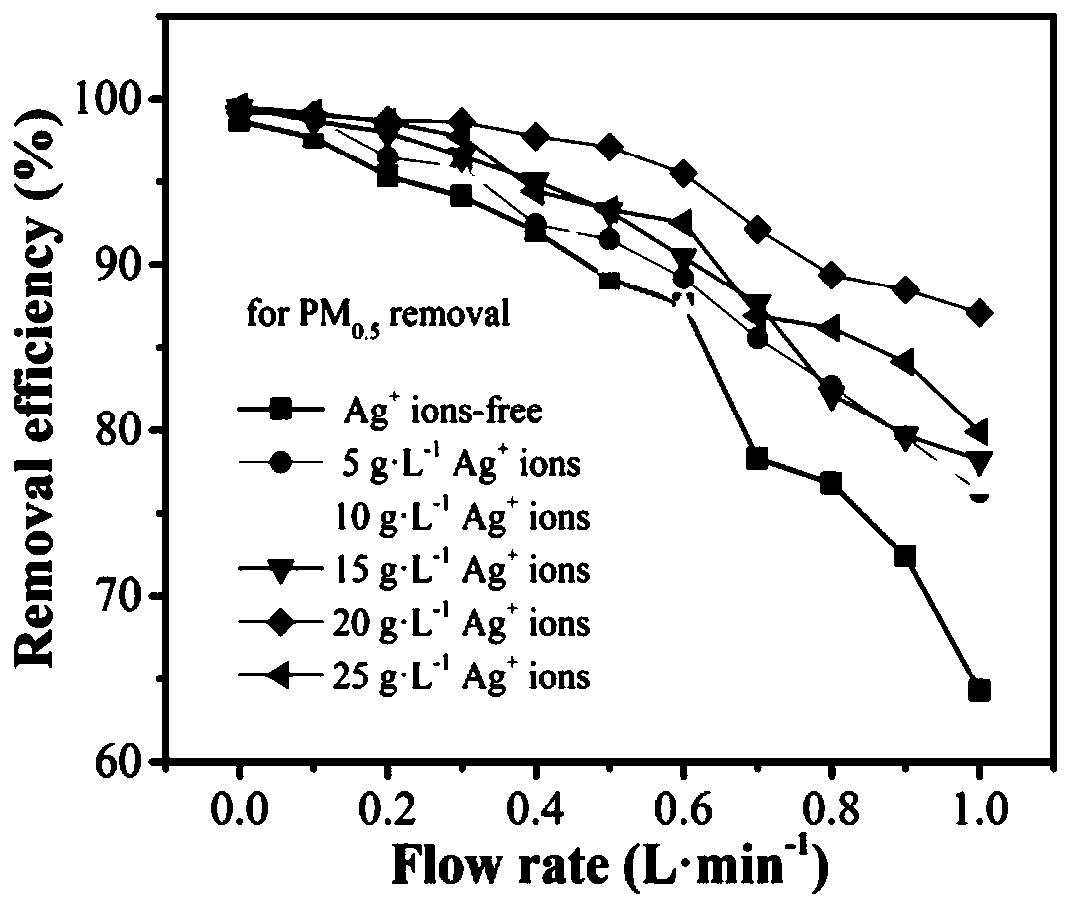

[0035] The same as the above example 1, the difference is that in step (2) after "... constant temperature magnetic stirring for 12 hours to make the solution transparent and clear", then add 50 mg of silver nitrate powder, after ultrasonic treatment for 0.5 min, constant temperature magnetic stirring for 1 hour.

Embodiment 3

[0037] Same as above Example 2, the difference is that 100 mg of silver nitrate powder is added in step (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com