Shredding machine blade and machining process thereof

A shredder and blade technology, which is applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve the problems that the shredder blade is prone to cracks, the particle size does not meet the requirements, and the service life of the blade is increased. Easy to install up and down, small slip coefficient, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

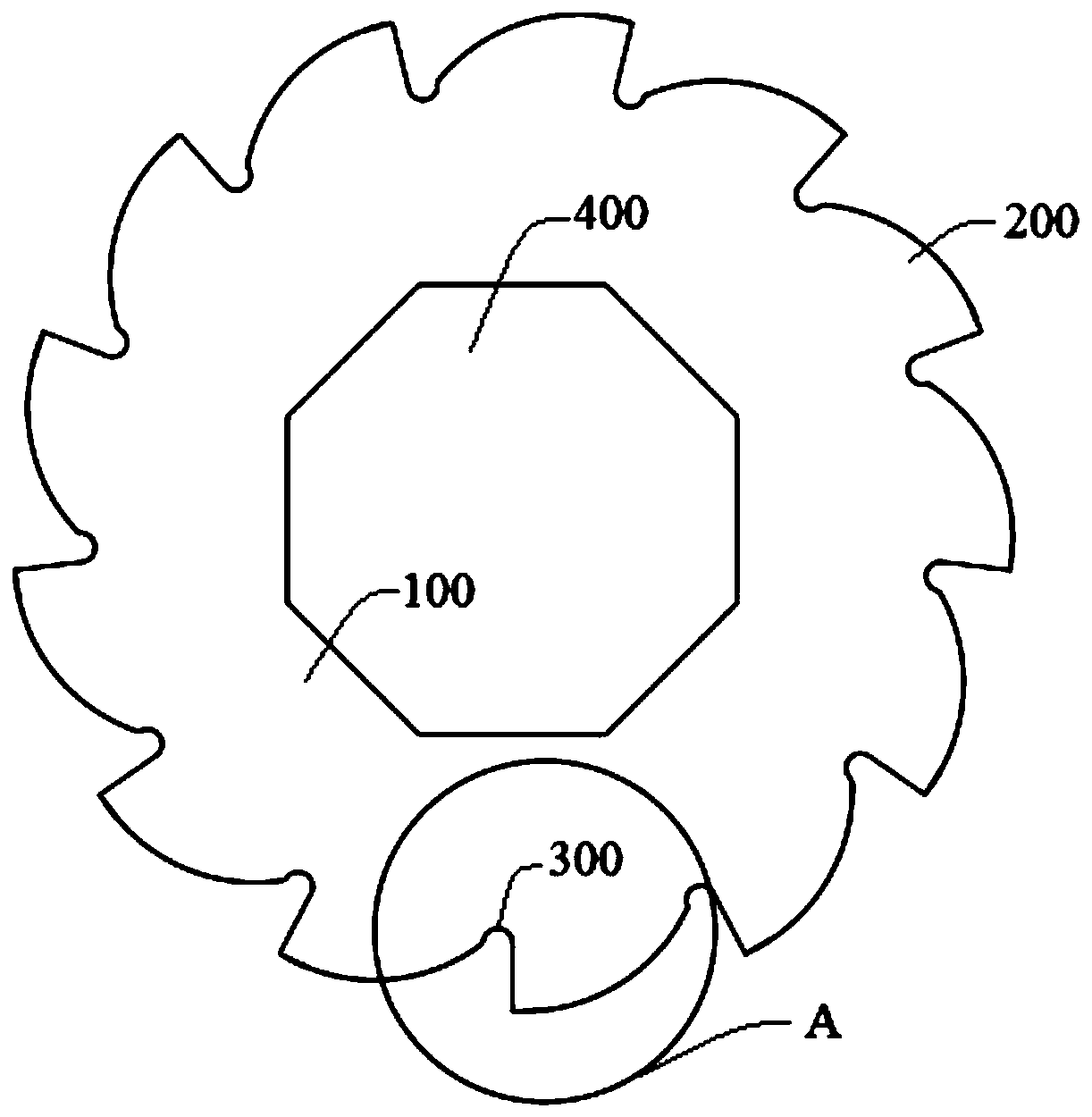

[0053] Please refer to figure 1 and figure 2 , the shredder blade of this embodiment includes a blade body 100, and the blade body 100 is provided with a cutter head 200, a groove 300 and a mounting hole 400, wherein n cutter heads are provided, n=13, and the groove 300 is located in At the joint between adjacent cutter heads 200, the mounting hole is a regular octagon, and the radius of the regular octagon is r 0 = 50mm.

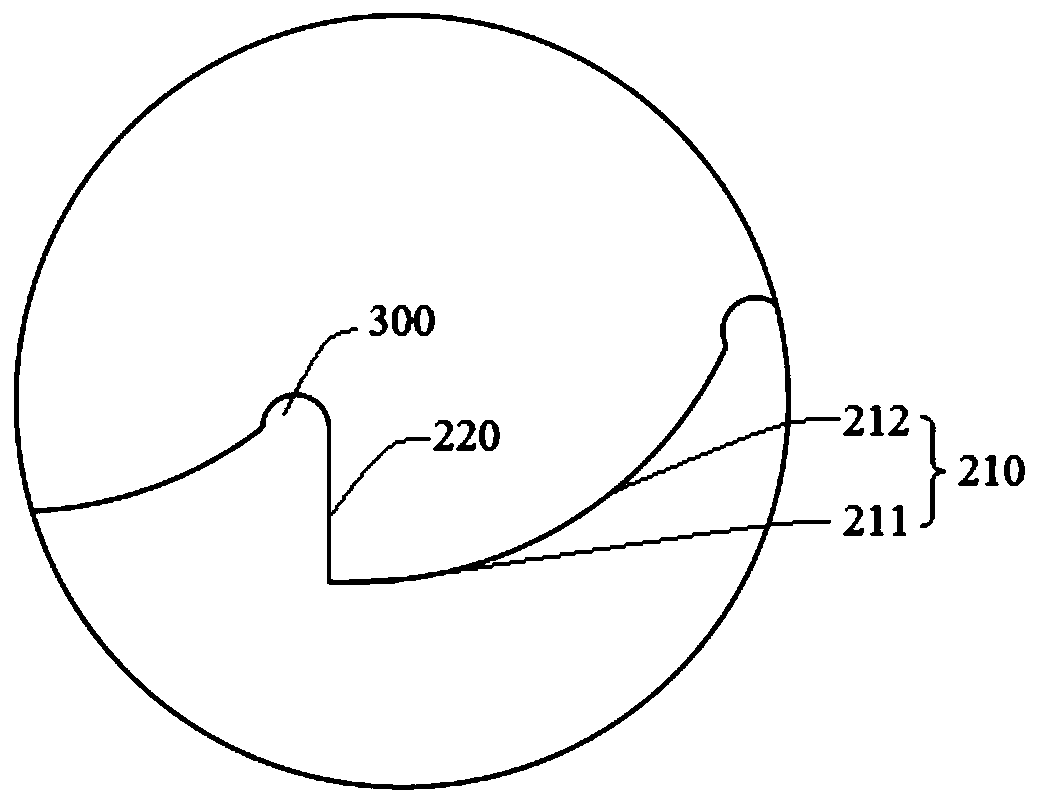

[0054] Specifically, combining image 3 As shown, the cutter head 200 includes a blade 210 and a blade back 220. The cutting angle of the blade 210 is 25° to 35°, and the blade 210 is formed by connecting multiple small arc-shaped blades, so that the materials are subjected to different pressures during the shearing process. The shear force in the direction, and then the size of the crushed material is smaller; the radius of the circle where the arc-shaped blade is located is different, and in the processing direction of the blade to shred the material,...

Embodiment 2

[0066] This embodiment is basically the same as Embodiment 1, except that the groove surface of the groove 300 is a spherical crown surface.

[0067] The groove surface of the groove 300 in this embodiment is a spherical crown surface. While the spherical crown surface has the advantages of a circular arc surface, the spherical crown surface can also disperse the received impact force to the surroundings evenly, and the force direction of each point can extend to the spherical surface. The spherical center of the crown ensures uniform stress at each point, reduces impact cracks, and further enhances the impact resistance of the blade. to combine Figure 5 As shown, the groove surface is a groove 300 of a spherical crown surface, the notch of the groove 300 is arc-shaped, and the section of the notch is a radius r 1 = r 0 / n semicircle, about r 1 =3.85mm, the distance from the bottom of the spherical crown groove to the highest point of the groove h=r 0 / n+0.3, ie h=4.15mm....

Embodiment 3

[0078] This embodiment is basically the same as Embodiment 1, except that this embodiment is a shredder blade in which the length and dimension of the blade 210 in Embodiment 1 are doubled, the angle dimension remains unchanged, and the components of the forged blank And the mass percentage is different.

[0079] Specifically, the radius of the regular octagonal mounting hole in this embodiment is r 0 =100mm; the cutting angle of the cutting edge 210 is 25°~35°, and the radius of the circle where the first cutting edge 211 is located is R 1 =222mm, the arc length is 11.52±0.3mm, the radius of the circle where the second cutting edge 212 is located is R 2 =74mm, the arc length is 77.5±0.3mm, where R 1 = 3R 2 The connection between the first cutting edge 211 and the second cutting edge 212 of the present embodiment is smooth, and the radius ratio of the circle where each small arc-shaped blade of the tool of the present invention is on the surface is reasonable, and after bei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com