Polycrystalline silicon ingot mould, application method and coating preparation method

A technology for polycrystalline silicon ingots and silicon ingots, which is applied to the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of no coating, and the silicon ingots are not easy to take out, so as to reduce the difficulty of drafting and improve the drafting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

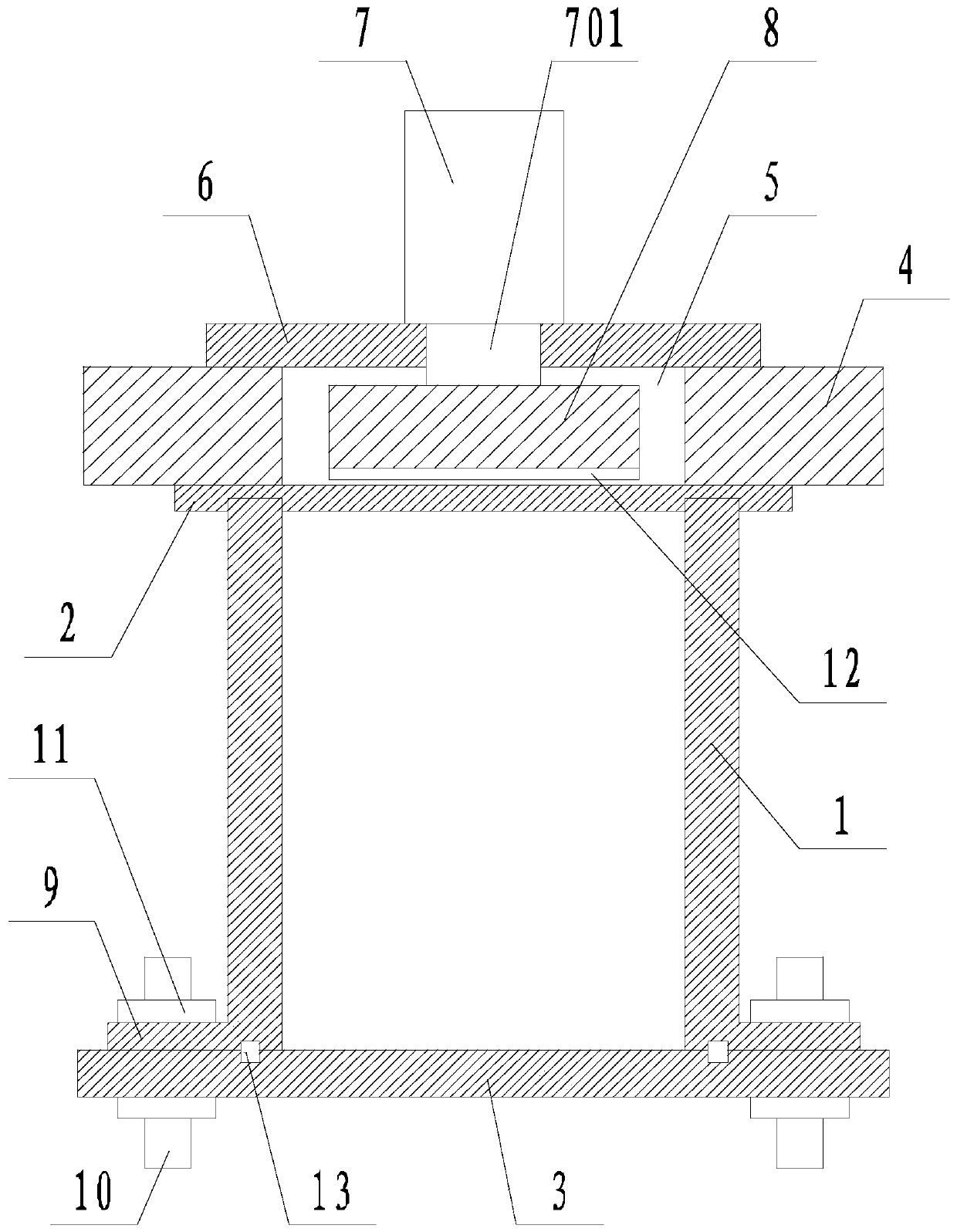

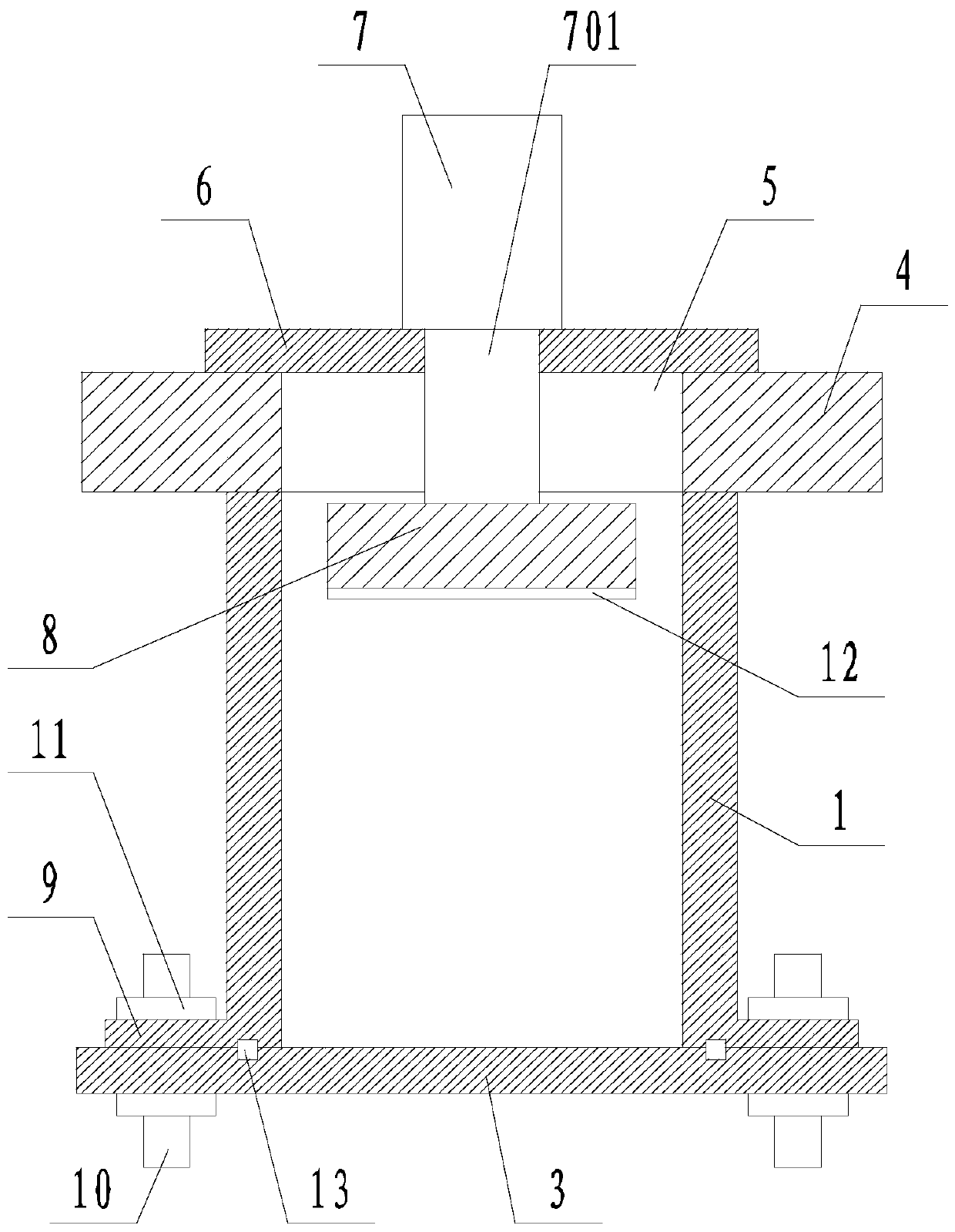

[0044] Such as figure 1 and figure 2 A polysilicon ingot mold shown includes a mould. The mold includes a side wall 1, a mold top 2, and a mold bottom 3. The upper and lower ends of the side wall 1 are open, and the mold top 2 is placed on the side wall. 1, the bottom of the mold 3 is detachably connected to the bottom of the side wall 1, and the holding part 4 is placed on the top of the mold 2, and the through hole 5 communicating up and down is opened on the holding part 4. The mounting plate 6 is fixed, and the linear driving device 7 with the driving end 701 facing downward is arranged on the mounting plate 6. The driving end 701 of the linear driving device 7 passes through the mounting plate 6 and enters the through hole 5. The driving end The bottom of 701 is fixedly connected to the draft push plate 8; the side wall 1, the mold top 2, and the mold bottom 3 are all made of polysilicon material; the inner surface of the side wall 1, the bottom surface of the mold top ...

Embodiment 2

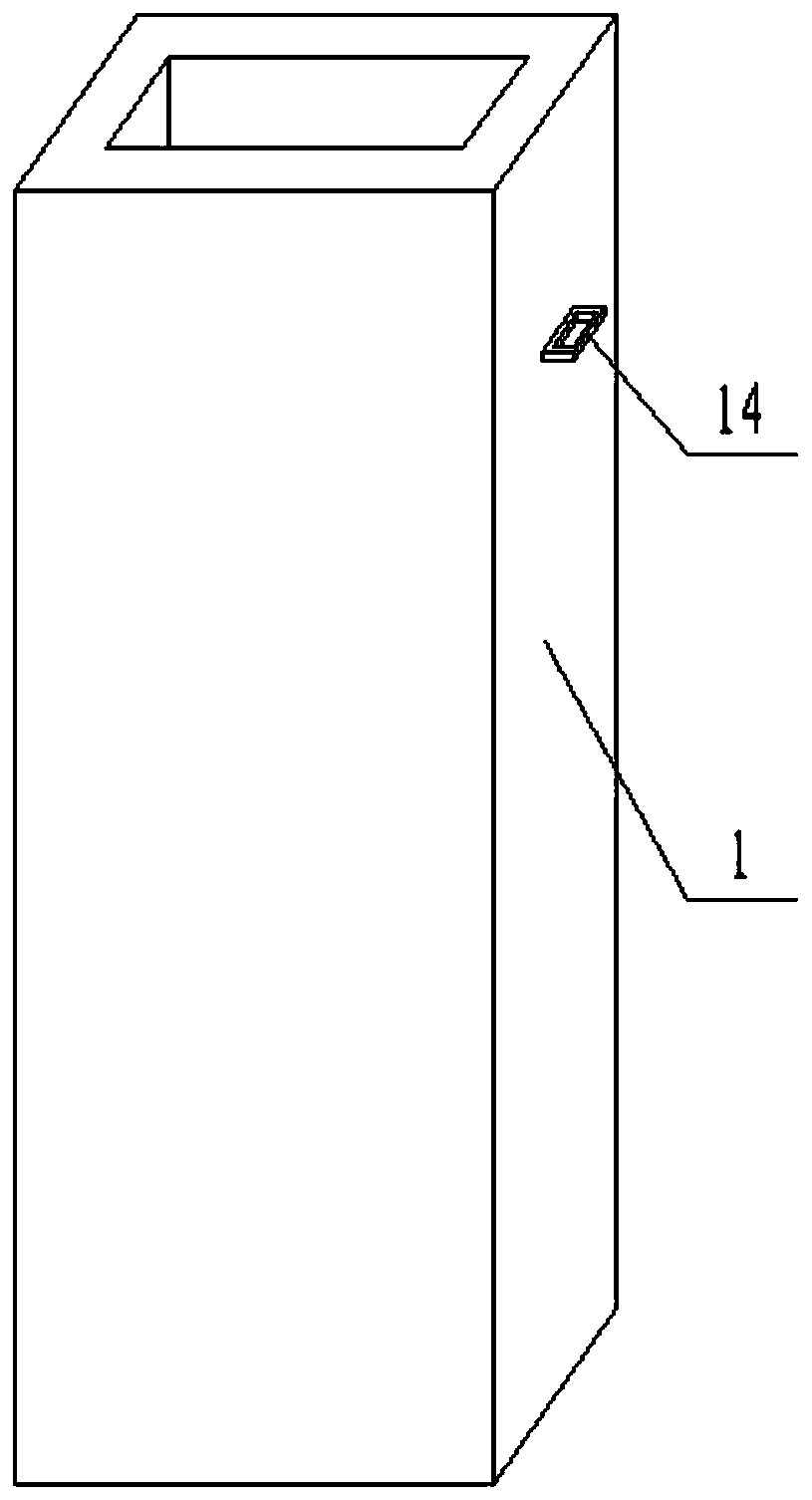

[0046] Such as figure 1 and figure 2In the shown polysilicon ingot mold, on the basis of Example 1, the side wall 1 is a cuboid structure with open upper and lower ends and a hollow interior; the opposite sides of the side wall 1 are fixed with lifting lugs 14 . The bottom surface of the mold top 2 is provided with a slot matching the top of the side wall 1, and the top of the side wall 1 is inserted into the slot; flange 9, the bottom surface of the flange 9 is in contact with the upper surface of the mold bottom 3, and also includes bolts 10 penetrating through the flange 9 and the mold bottom 3, and nuts 11 are sleeved at the upper and lower ends of the bolt 10; 4 is a stainless steel plate; the mounting plate 6 is welded to the holding member 4 . A layer of rubber pad 12 is laid on the bottom surface of the draft push plate 8; the thickness of the rubber pad 12 is 1-2 cm. The use process of this embodiment is as follows:

[0047] (A) The mold bottom 3 is placed flat ...

Embodiment 3

[0055] The preparation method of big ingot paint, comprises the following steps:

[0056] (a) Fully grind and mix 50 parts of silicon carbide, 25-30 parts of silicon nitride, 10-12 parts of calcium silicate, 15-20 parts of bentonite, 6-8 parts of adhesive, and 1-2 parts of graphite powder;

[0057] (b) Put the mixed raw materials into a reaction kettle, add a solvent, and stir for 30 minutes at 85-90°C under normal pressure;

[0058] (c) Add 8 to 10 parts of sodium tripolyphosphate, 3 to 5 parts of acrylamide and / or polyacrylamine into the reaction kettle, raise the temperature in the kettle to 150~200°C, and raise the pressure in the kettle to 1.5~ 2 times atmospheric pressure, stirring for 60min;

[0059] (d) discharge to normal pressure in the reaction kettle, make the inside of the reaction kettle be cooled to room temperature;

[0060] (e) The finished product in the reactor should be sealed and stored.

[0061] Preferably, in the process of cooling the interior of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com