Lever-type bidirectional surface acoustic wave acceleration sensor

An acceleration sensor and surface acoustic wave technology, applied in the field of sensors, can solve problems such as inability to judge direction, poor detection accuracy, and short service life, and achieve the effects of increasing structural sensitivity, high adaptability, and avoiding poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

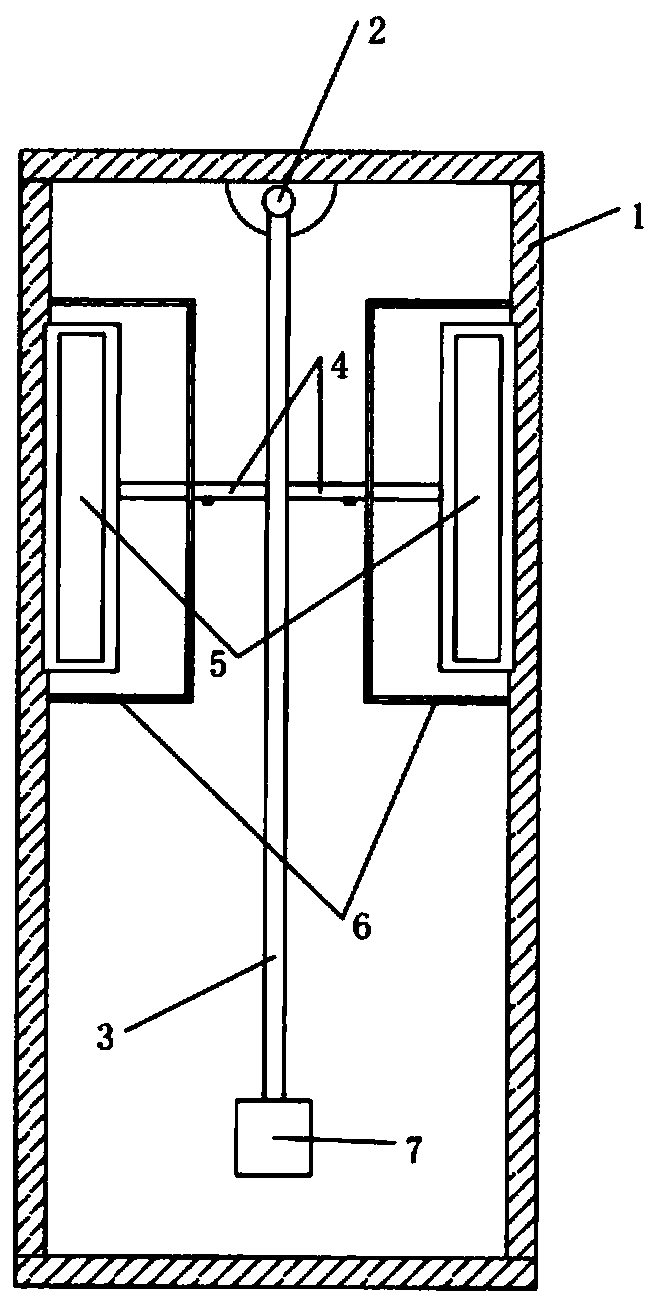

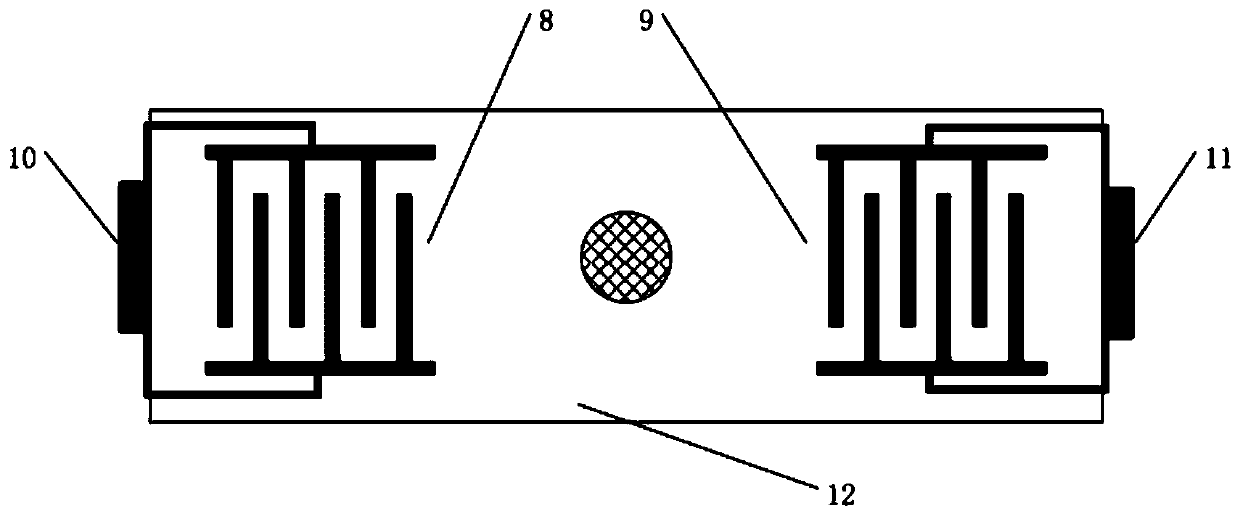

[0041] The specific implementation manners of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0042] A lever type two-way surface acoustic wave acceleration sensor, such as figure 1 As shown, it includes a metal shell 1, a movable bearing 2, a rigid lever 3, two pressure transmission rods 4, an inertial mass 7 and two surface acoustic wave sensor devices 5; a movable bearing 2, a rigid lever 3, a pressure transmission rod 4, Both the inertial mass 7 and the surface acoustic wave sensor 5 are located in the metal casing 1;

[0043] The movable bearing 2 is fixed on the center of the top surface of the metal casing 1;

[0044] One end of the rigid lever 3 is fixedly connected with the movable bearing 2, and the other end is connected with an inertial mass block 7;

[0045] The surface acoustic wave sensor devices 5 are respectively connected to the metal casing 1 and are symmetrical about the rigid lever 3;

[0046] One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com