Method for preparing electrochromic device

An electrochromic device and electrochromic layer technology, which can be used in instruments, vacuum evaporation plating, coatings, etc., can solve the problems of slow discoloration speed, narrow discoloration range of electrochromic devices, and low transparency in faded state, etc. Fast color changing speed, high transparency, wide color changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

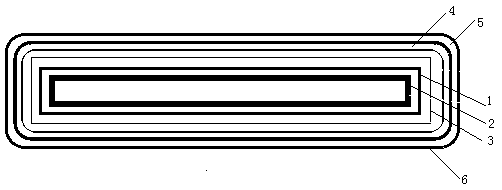

[0026] The preparation method of the electrochromic device of the present embodiment, wherein, adopts the plasma vacuum coating device, such as figure 1 As shown, it includes the target 3 fixedly set by the N magnet 1 and the S magnet 2, and the outer circumference of the target 2 is sequentially provided with Ar / O 2 Mixed gas 4, air extraction channel 5 and shielding cover 6.

[0027] The preparation method of the electrochromic device of this embodiment, the preparation method comprises the following steps:

[0028] (1) Preparation of the first transparent conductive layer: select a clean and highly transparent material as the substrate, clean the substrate, and then form a layer of thickness on the upper surface of the cleaned substrate by vacuum coating, evaporation coating or sol-gel process 200nm, sheet resistance 20ohm, visible light average transmittance > 85% ITO transparent conductive film, and then form the first transparent conductive layer on the upper surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com