Preparation method of cadmium sulfide pectinate semiconductor micro/nano material

A micro-nano material, cadmium sulfide technology, applied in the field of photochromism, to achieve the effect of easy realization, simple production and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

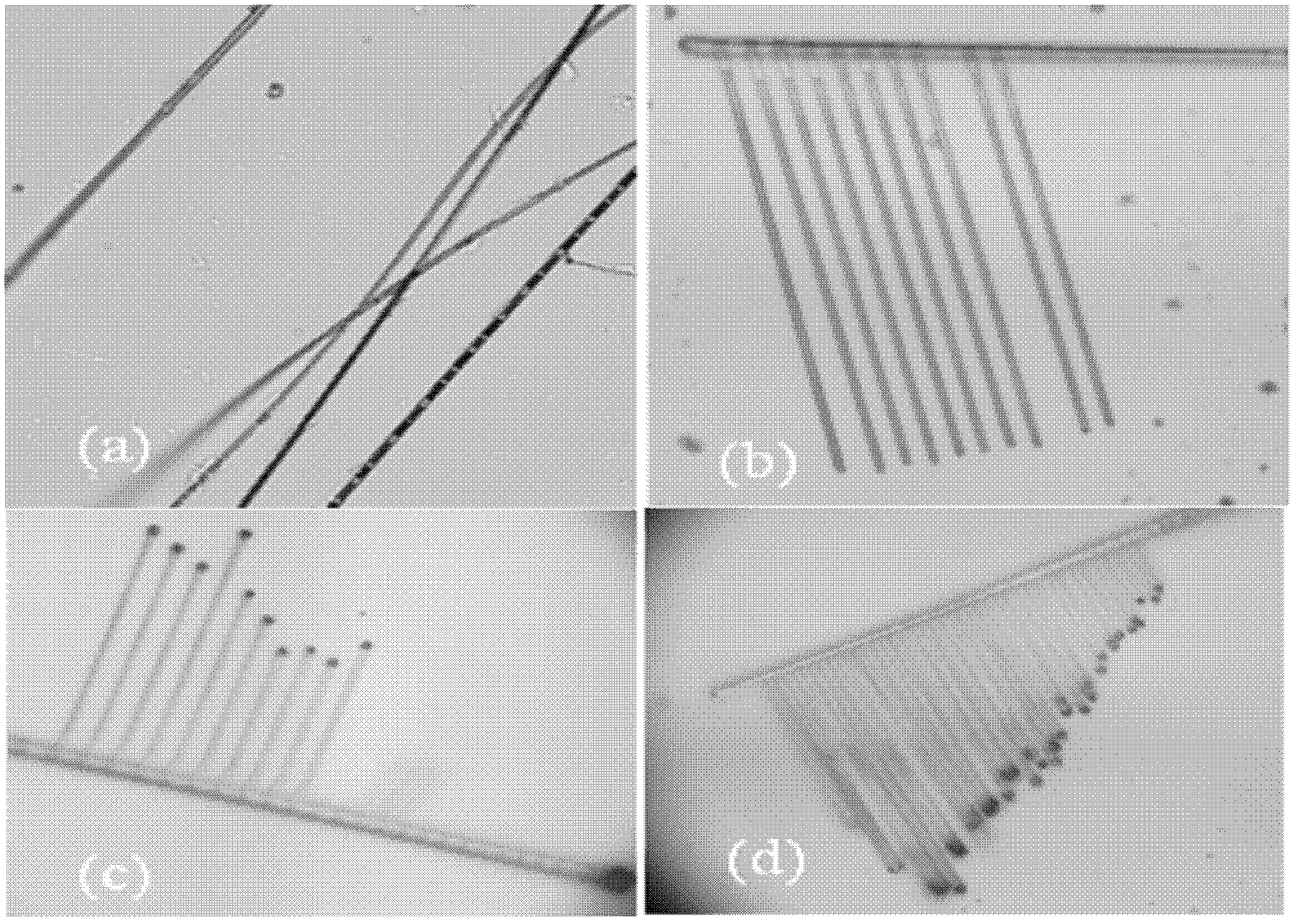

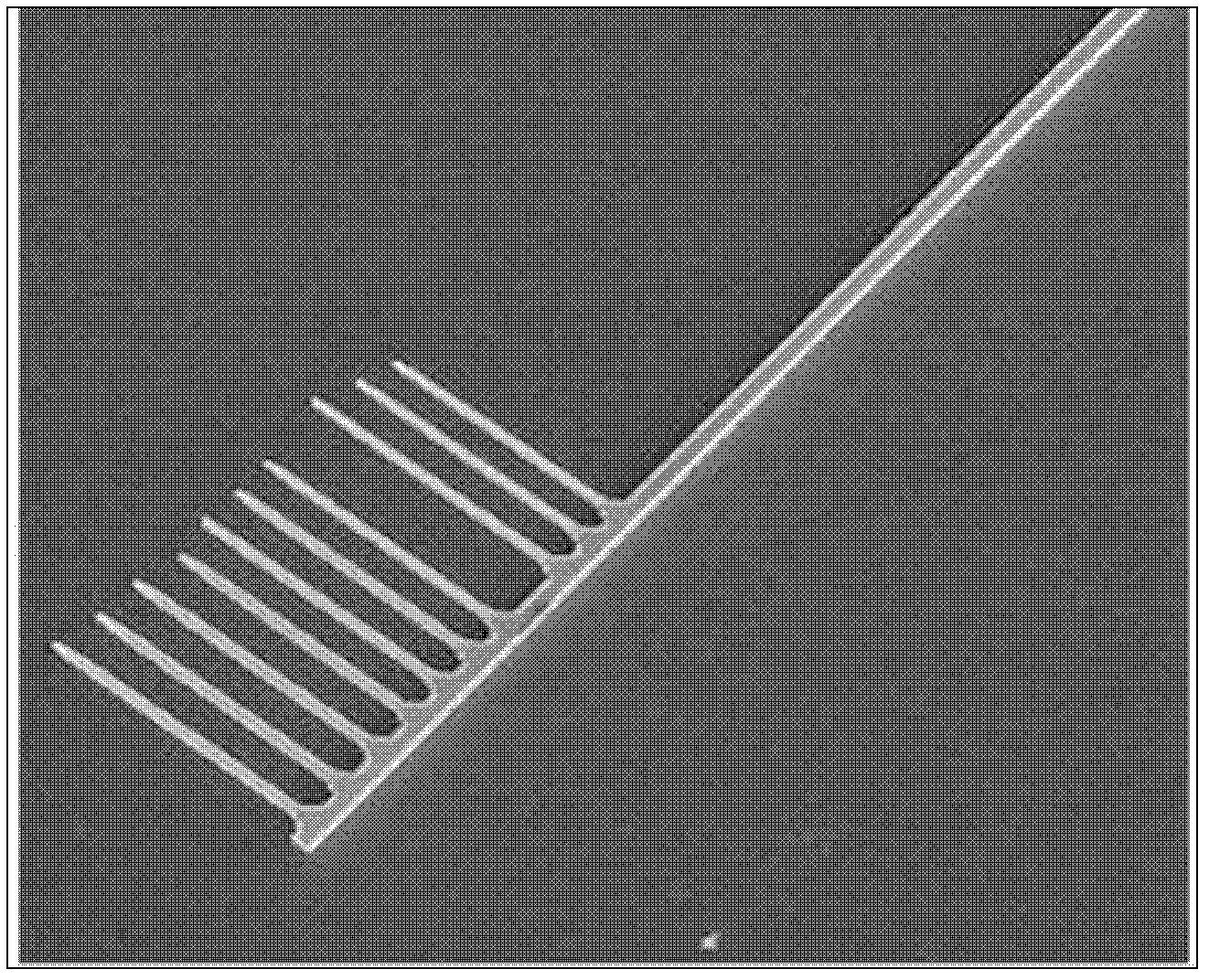

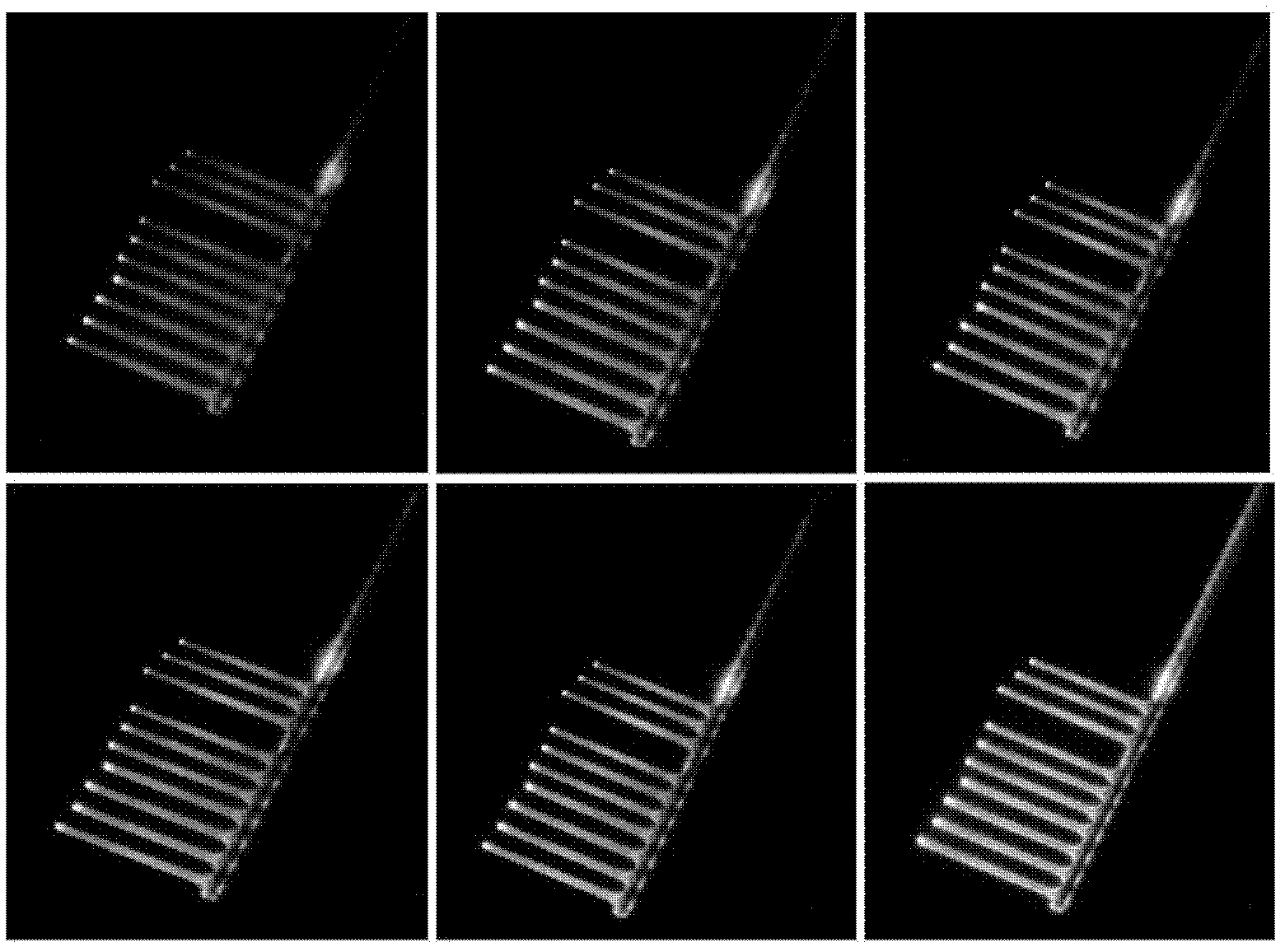

[0027] A cadmium sulfide comb-shaped semiconductor micro-nano material, the material is cadmium sulfide (CdS) doped with tin (Sn), calculated based on the total amount of the material, using transmission electron microscope (TEM) or scanning electron microscope (SEM) The attached energy spectrometer can characterize the molar content of tin within 1%.

[0028] A preparation method of cadmium sulfide comb-shaped semiconductor micro-nano material, the steps are: cadmium sulfide and tin dioxide are uniformly stirred in a mortar at a molar ratio of 100:8 for 10 minutes; silicon wafers are washed in an ultrasonic cleaner with absolute ethanol Clean the inside for 10 minutes. After drying, use the ion sputtering instrument to plate gold for 60 seconds. Clean the porcelain boat and quartz tube for later use. Then put CdS and SnO 2 Put the mixture into the porcelain boat and place the porcelain boat in the center of the quartz tube. Put a gold-plated silicon wafer in another porcelain b...

Embodiment 2

[0030] A preparation method of cadmium sulfide comb-shaped semiconductor micro-nano material. The steps are: cadmium sulfide and tin dioxide are uniformly stirred in a mortar for 10 minutes at a molar ratio of 100:10; silicon wafers are washed in an ultrasonic cleaner with absolute ethanol Clean the inside for 10 minutes. After drying, use the ion sputtering instrument to plate gold for 60 seconds. Clean the porcelain boat and quartz tube for later use. Then put CdS and SnO 2 Put the mixture into the porcelain boat and place the porcelain boat in the center of the quartz tube. Put a gold-plated silicon wafer in another porcelain boat, and place it on the upstream of the quartz tube air flow, 11 cm from the center of the quartz tube. Put the quartz tube into the tube furnace, connect the flow meter upstream of the quartz tube first, connect the exhaust system, connect the exhaust gas treatment system downstream, and then pass in a mixture of argon and hydrogen. After one hour of...

Embodiment 3

[0036] A method for preparing cadmium sulfide comb-shaped semiconductor micro-nano materials, the steps are: cadmium sulfide and tin dioxide are uniformly stirred in a mortar for 10 minutes at a molar ratio of 100:12; silicon wafers are washed in an ultrasonic cleaner with absolute ethanol Clean the inside for 10 minutes. After drying, use the ion sputtering instrument to plate gold for 60 seconds. Clean the porcelain boat and quartz tube for later use. Then put CdS and SnO 2 Put the mixture into the porcelain boat and place the porcelain boat in the center of the quartz tube. Put a gold-plated silicon wafer in another porcelain boat, and place it on the upstream of the quartz tube air flow, 11 cm from the center of the quartz tube. Put the quartz tube into the tube furnace, connect the flow meter upstream of the quartz tube first, connect the exhaust system, connect the exhaust gas treatment system downstream, and then pass in a mixture of argon and hydrogen. After one hour of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com