Low-toxicity heat-sensitive quantum dot material and preparation method thereof

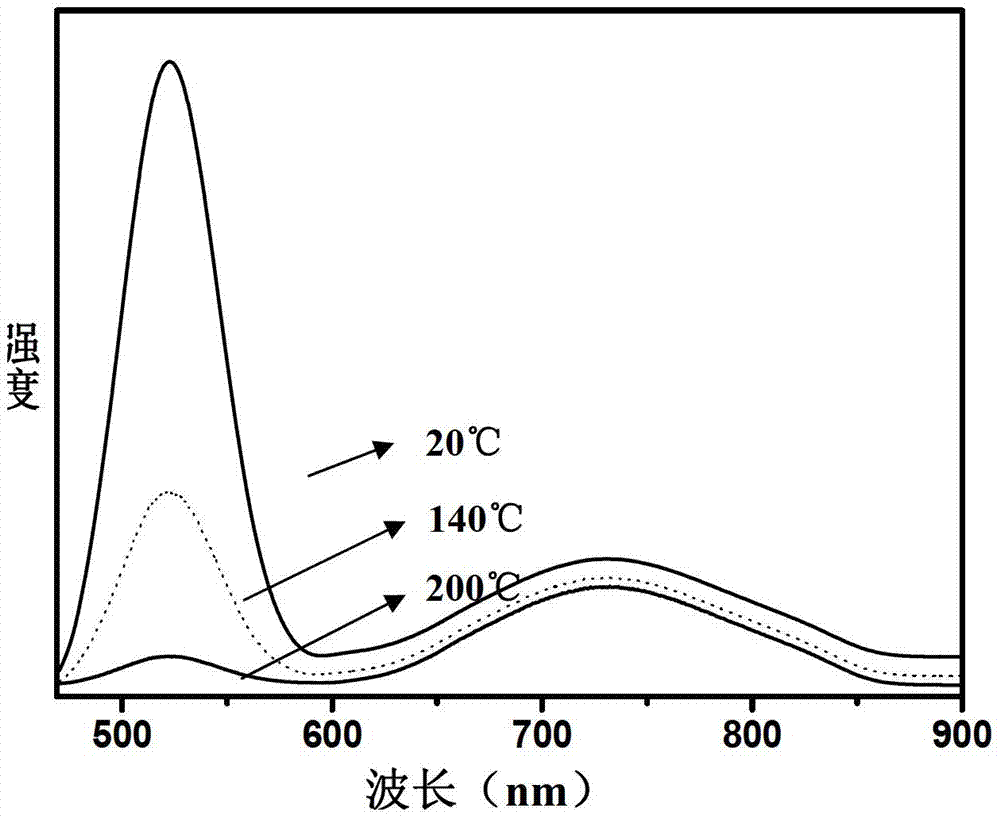

A quantum dot material and quantum dot technology, applied in the field of low-toxicity heat-sensitive quantum dot materials and their synthesis, can solve the problem of changing temperature color without paying attention to the sensitivity of heat-sensitive materials, there is no clear correspondence between temperature and color, and the change of luminous color Insufficient clarity and other problems, to achieve the effect of wide color range, good monodispersity and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

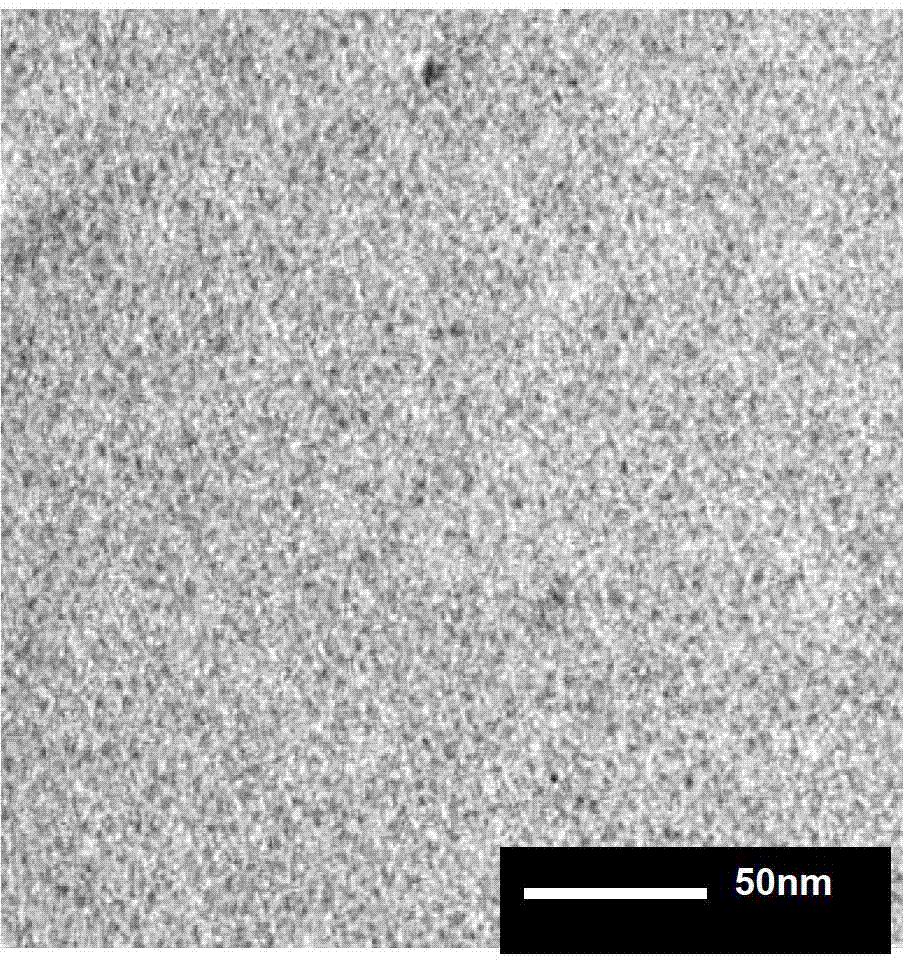

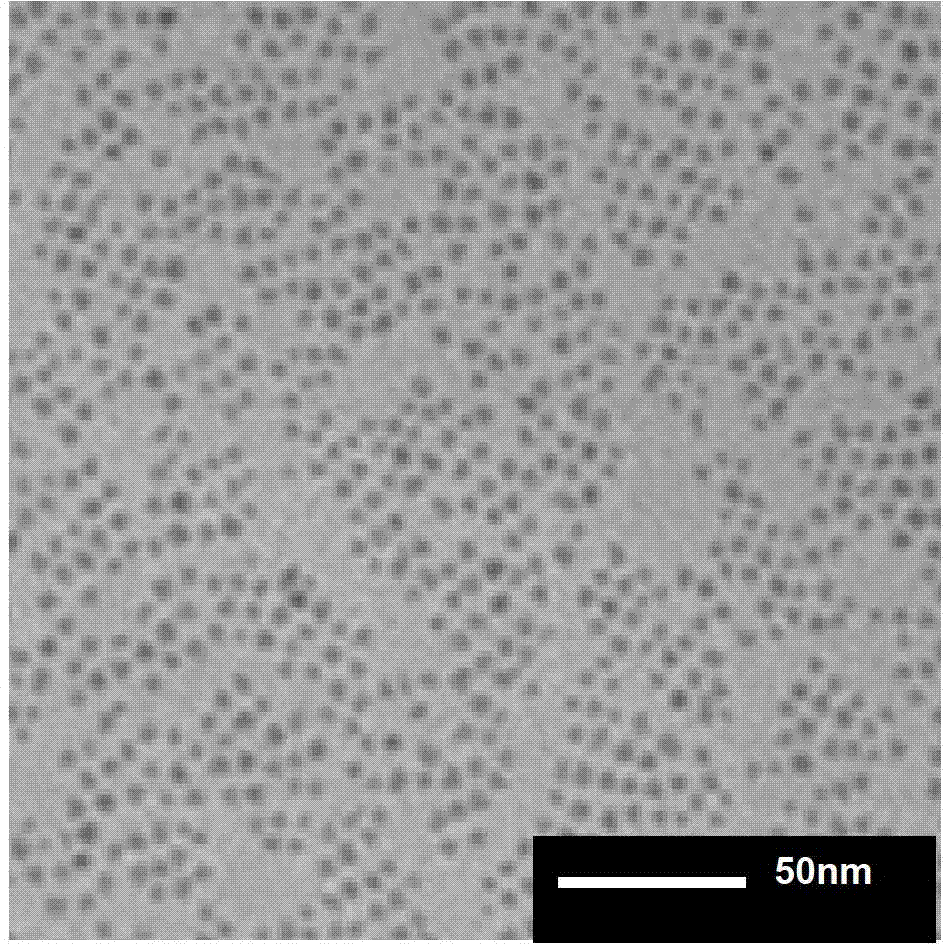

[0043] First, prepare InP quantum dots: Take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 80 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 In a milliliter concentration of 0.2mol / L 3-(trimethylsilyl) phosphorus octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

[0044] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 60°C, and a total amount of 1 ml of octadecene solution of copper myristate with a concentration of 0.005mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 20 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is Cu:P=1:20 by molar ratio.

Embodiment 2

[0046] First, prepare InP quantum dots: Take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 100 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 0.2 mol / L 3-(trimethylsilyl) phosphine octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

[0047] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 80 ° C, and a total amount of 1 milliliter of octadecene solution of copper myristate with a concentration of 0.01 mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 30 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is the molar ratio Cu:P=1:10.

Embodiment 3

[0049] First, prepare InP quantum dots: take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 120 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 0.2 mol / L 3-(trimethylsilyl) phosphine octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

[0050] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 100° C., and a total amount of 1 milliliter of octadecene solution of copper myristate with a concentration of 0.02 mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 40 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is Cu:P=1:5 by molar ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com