Thermosensitive quantum dot material with core-shell structure and preparation method thereof

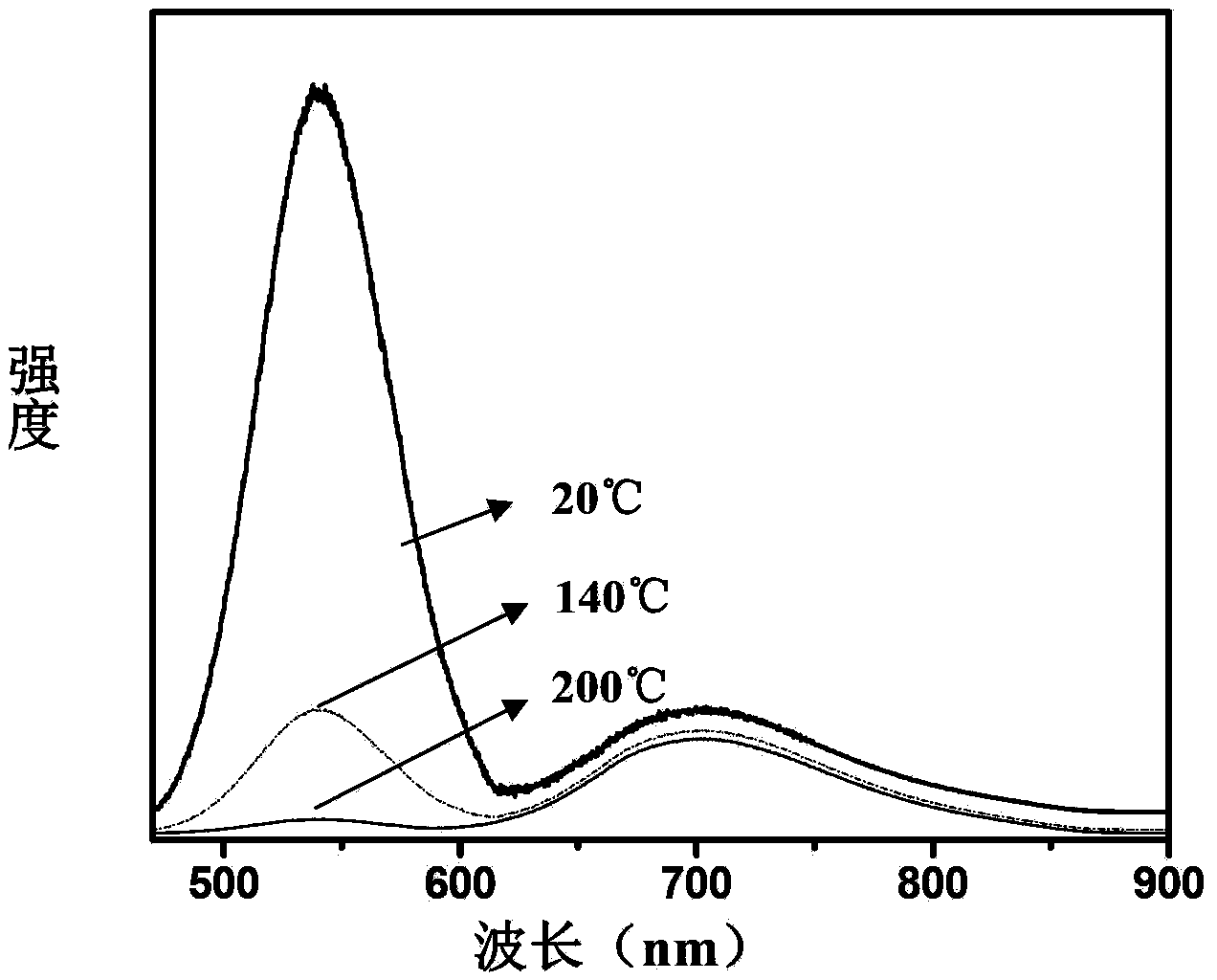

A technology of quantum dot material and core-shell structure, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of small span of temperature-changing color interval, unclear change of luminescent color, no clear correspondence between temperature and color, etc., and achieves wide discoloration range. , uniform size, good monodispersity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

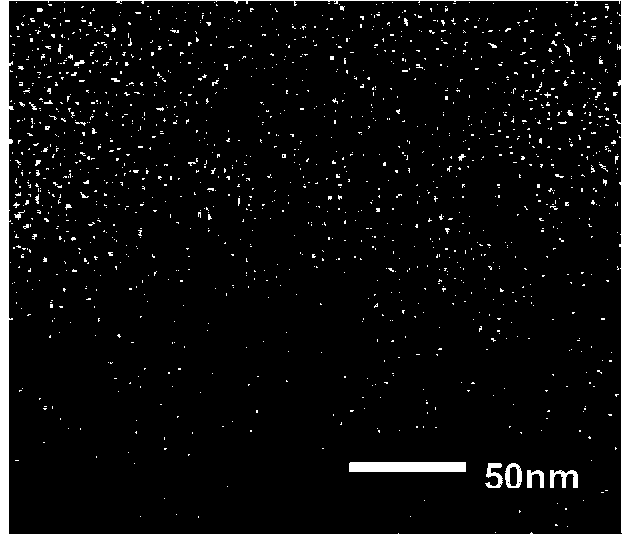

[0041] First, prepare InP quantum dots: Take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 80 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 In a milliliter concentration of 0.2mol / L 3-(trimethylsilyl) phosphorus octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

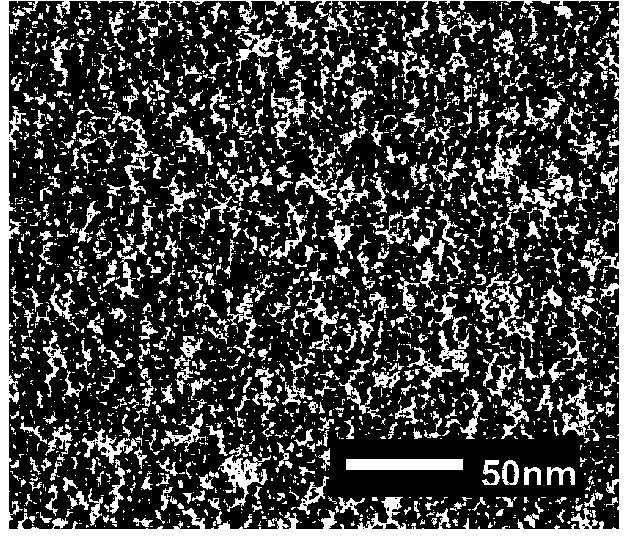

[0042] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 60°C, and a total amount of 1 ml of octadecene solution of copper myristate with a concentration of 0.005mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 20 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is Cu:P=1:20 by molar ratio.

Embodiment 2

[0044] First, prepare InP quantum dots: Take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 100 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 In a milliliter concentration of 0.2mol / L 3-(trimethylsilyl) phosphorus octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

[0045] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 80 ° C, and a total amount of 1 milliliter of octadecene solution of copper myristate with a concentration of 0.01 mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 30 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is the molar ratio Cu:P=1:10.

Embodiment 3

[0047] First, prepare InP quantum dots: take 0.2 millimoles of indium acetate and 0.7 millimoles of myristic acid and add them to 5 milliliters of octadecene, heat up to 120 ° C, after vacuuming, heat up to 188 ° C under the protection of nitrogen, inject 0.5 In a milliliter concentration of 0.2mol / L 3-(trimethylsilyl) phosphorus octadecene solution and 1.2 mmol octylamine, after injection, naturally cool down to 178°C, keep the temperature at 178°C for 30 minutes to obtain InP quantum dots , the obtained InP quantum dots have a diameter of about 2nm.

[0048] Then, Cu doping is carried out: the prepared InP quantum dots are directly cooled to 100° C., and a total amount of 1 milliliter of octadecene solution of copper myristate with a concentration of 0.02 mmol / L is dropped into the system, and then the temperature is raised to 150°C, keep the temperature for 40 minutes to get a Cu-doped InP quantum dot nucleus solution, the amount of Cu doped is Cu:P=1:5 by molar ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com