Thick copper circuit board and manufacturing method thereof

A technology of thick copper circuit board and manufacturing method, which is applied in the field of circuit board manufacturing, can solve the problems of gas residue, thick copper layer of thick copper circuit board, etc., and achieve the effect of avoiding dryply defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

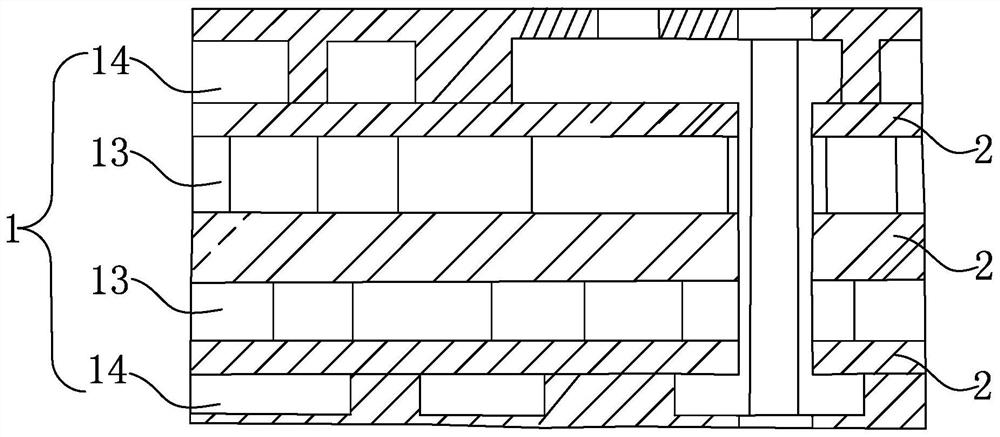

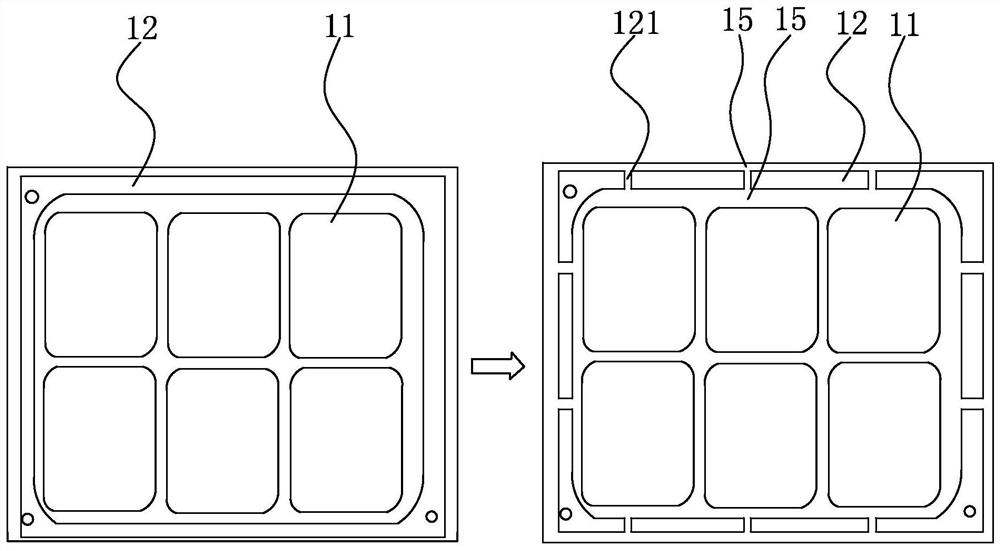

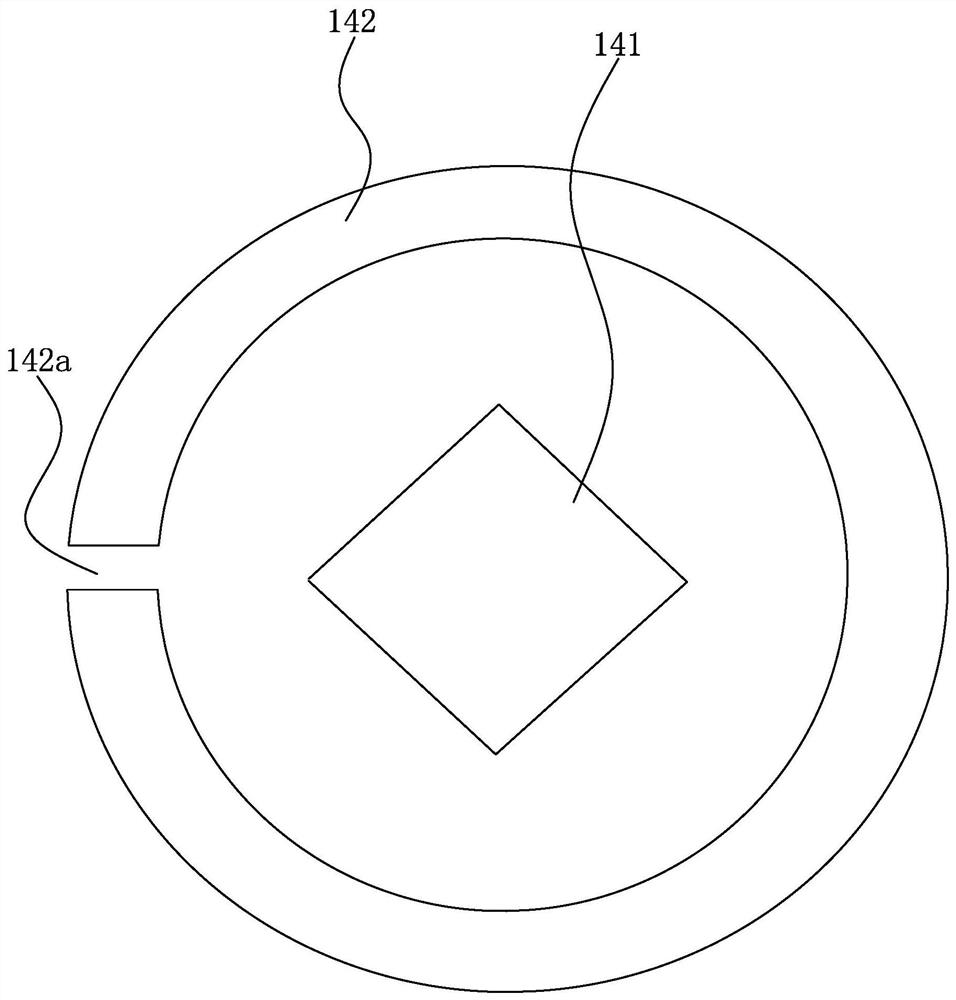

[0061] Example 1: See attached figure 1 to attach image 3 , the present embodiment provides a thick copper circuit board, including a multilayer graphic circuit layer 1 and a multilayer insulating dielectric layer 2, as attached figure 1 As shown, the insulating dielectric layer 2 is arranged between the two adjacent graphic circuit layers 1, and the insulating dielectric layer 2 is a prepreg, so as to isolate the two circuit layers and avoid the short circuit of the graphic circuit layer; The graphic circuit layer 1 is provided with at least one graphic circuit unit 11 , of course, a plurality of graphic circuit units may be provided as required, specifically designed according to the shape and size of the required graphic circuit unit. The edge of the graphic circuit layer is surrounded by a process edge 12, which is used to ensure the efficiency and quality of the thick copper circuit board in the subsequent assembly process, and can also disperse the heat received by the...

Embodiment 2

[0066] Example 2: See attached Figure 4 to attach Figure 5 , the present embodiment provides a method for manufacturing a thick copper circuit board, comprising the following steps:

[0067] S1. Material cutting: Cut the qualified thick copper clad laminate into a predetermined size and shape, and then clean and dry the surface. The thick copper clad laminate is made of cured resin film and 3OZ, 4OZ, 5OZ, 6OZ copper foil and other copper foils of the same or different thickness;

[0068] S2. Transfer of inner layer graphic circuit: a layer of photosensitive material is pasted on the copper clad core board, and then the negative graphic black film is used for counter-position exposure, so that the photosensitive material in the circuit area is cured during the exposure process, and the image is completed transfer. The black film is provided with graphic light blocking points, the shape and size of the graphic light blocking points are consistent with the shape and size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com