Freezing process for fishes

A process and fish technology, which is applied in the preservation of meat/fish, preservation of meat/fish by freezing/cooling, food science, etc. and other problems to achieve the effect of avoiding freezing water loss, slow freezing and fast freezing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The freezing process of fish in this embodiment adopts the following steps:

[0034] 1) Fishing: Choose healthy and adult live golden pomfret for fishing.

[0035] 2) Cleaning: Clean the dirt and gravel on the surface of the golden pomfret with clean water.

[0036] 3) Pre-cooling: within 2 hours after fishing, put the live golden pomfret directly into an ice paddle (liquid ice) with an ice crystal size of 0.25 to 0.50 mm at 0°C for 1 to 2 hours.

[0037] 4) Quick freezing: Adjust the temperature of the liquid nitrogen low-temperature quick-freezer to -100°C, and the wind speed to 1.5-2.0m / s; after the temperature in the quick-freezing room drops to -100°C and stabilizes for at least 5 minutes, open the freezing chamber door and quickly Put in the pre-cooled whole fish (put in within 3h after fishing), and immediately close the freezing chamber door, the quick freezing time is 20-30min.

[0038] 5) Packaging: Cool the packaging bag below -18°C, and quickly freeze the golden pomf...

experiment example

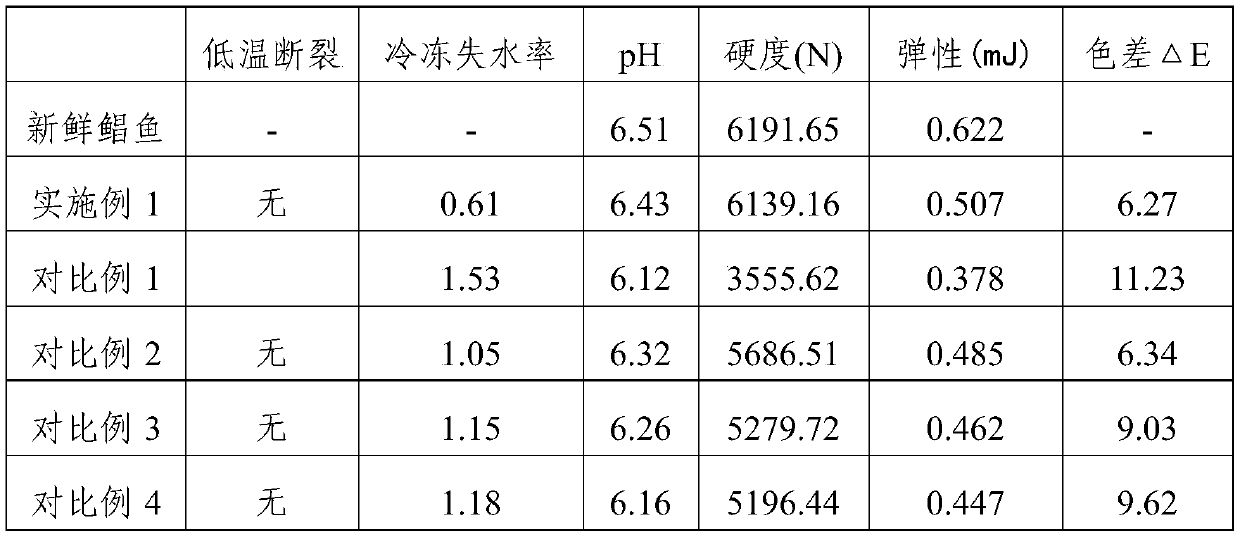

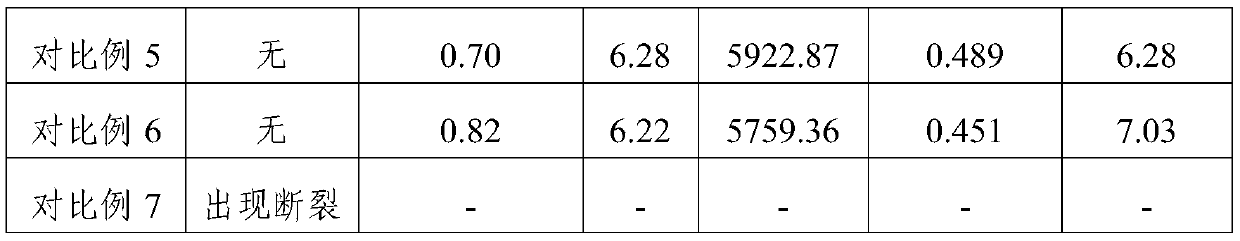

[0060] The surface cracks, frozen water loss rate, pH, hardness and color difference of fresh golden pomfret and golden pomfret treated by different freezing processes of the above-mentioned examples and comparative examples were tested. The freezing water loss rate is measured by weighing the golden pomfret before and after thawing. The pH is measured by a pH meter. The hardness and elasticity are measured by a texture meter, and the color difference is measured by a color difference meter. Six samples are tested for each quality index, and the obtained experimental values are averaged after removing the maximum and minimum values.

[0061] Table 1 Quality Test Results

[0062]

[0063]

[0064] Since the surface of the golden pomfret in Comparative Example 7 had been frozen at low temperature, the process was directly ruled out without measuring other quality indicators. The frozen whole fish body (golden pomfret) prepared by the process of pre-cooling at 0°C and 1.5~2.0m / s@...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com