Preparation method of instant umami mushroom soup powder

A mushroom soup and instant technology, applied in the field of edible mushrooms, to achieve the effect of rich nutrition, short enzymatic hydrolysis time and sufficient release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

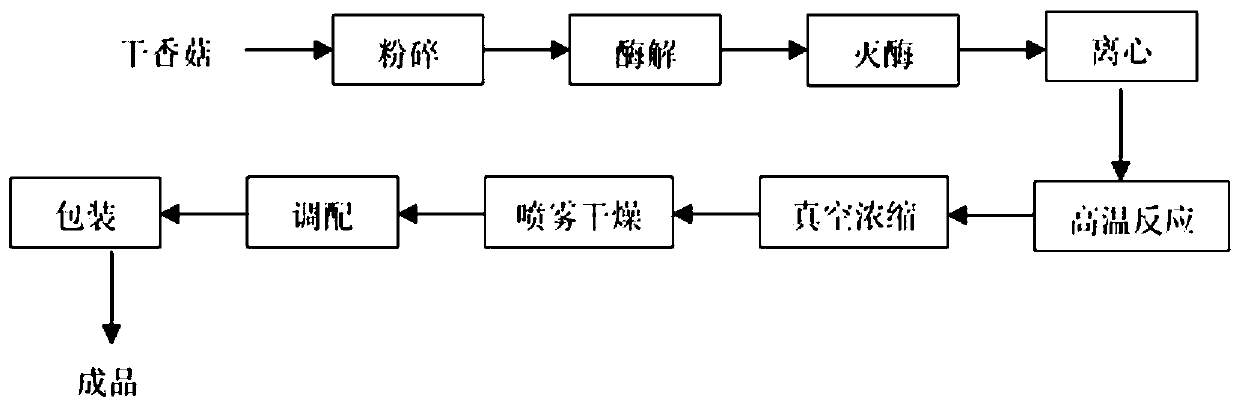

Image

Examples

Embodiment 1

[0032] A kind of fresh instant bacteria soup powder

[0033] (1) Preparation of shiitake mushroom stock solution: crush dried shiitake mushrooms through a 40-mesh sieve, add 1g of dried shiitake mushroom powder to 10ml of water to make a shiitake mushroom stock solution for later use;

[0034] (2) Enzymolysis: adjust the pH of the mushroom stock solution to 5.5 with hydrochloric acid at a concentration of 1.00mol / L, add 0.45% of cellulase and 0.25% of flavor protease for enzymolysis, and the enzymolysis temperature is 52°C. Enzymolysis for 82 minutes to obtain enzymolysis solution;

[0035] (3) Enzyme inactivation centrifugation: heat the enzymolysis solution at 92.5°C for 12.5 minutes to inactivate the enzyme, then centrifuge at 4500r / min for 12.5 minutes, and take the supernatant for later use;

[0036] (4) High-temperature reaction: Mix the supernatant with xylose, glucose, and L-cysteine at a mass ratio of 100:5:6.5:2.5, adjust the pH to 7.8, and react at 102°C for 80 m...

Embodiment 2

[0042] A kind of fresh instant bacteria soup powder

[0043] (1) Preparation of shiitake mushroom stock solution: crush dried shiitake mushrooms through a 40-mesh sieve, add 1g of dried shiitake mushroom powder to 10ml of water to make a shiitake mushroom stock solution for later use;

[0044] (2) Enzymolysis: Adjust the pH of the mushroom stock solution to 5.5 with hydrochloric acid at a concentration of 1.00 mol / L, add 0.3% of cellulase and 0.2% of flavor protease for enzymolysis, and the enzymatic hydrolysis temperature is 50°C. The enzymolysis time is 75min, and the enzymolysis solution is obtained;

[0045] (3) Enzyme inactivation centrifugation: heat the enzymolysis solution at 90°C for 10 minutes to inactivate the enzyme, then centrifuge at 4500r / min for 10 minutes, and take the supernatant for later use;

[0046] (4) High-temperature reaction: Mix the supernatant with xylose, glucose, and L-cysteine at a mass ratio of 100:4:5:2, adjust the pH to 7.8, and react at 10...

Embodiment 3

[0052] A kind of fresh instant bacteria soup powder

[0053] (1) Preparation of shiitake mushroom stock solution: crush dried shiitake mushrooms through a 40-mesh sieve, add 1g of dried shiitake mushroom powder to 10ml of water to make a shiitake mushroom stock solution for later use;

[0054] (2) Enzymolysis: Adjust the pH of the mushroom stock solution to 5.5 with hydrochloric acid at a concentration of 1.00 mol / L, add 0.6% of cellulase and 0.3% of flavor protease for enzymolysis, and the enzymatic hydrolysis temperature is 55°C. The enzymolysis time is 90min, and the enzymolysis solution is obtained;

[0055] (3) Enzyme inactivation centrifugation: heat the enzymolysis solution at 95°C for 15 minutes to inactivate the enzyme, then centrifuge at 4500r / min for 15 minutes, and take the supernatant for later use;

[0056] (4) High-temperature reaction: Mix the supernatant with xylose, glucose, and L-cysteine at a mass ratio of 100:6:8:3, adjust the pH to 7.8, and react at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com