Antifouling white shoe sole and preparation method thereof

A sole and anti-fouling technology, applied in the direction of soles, footwear, clothing, etc., can solve the problem of delayed yellowing, and achieve the effects of delaying yellowing, prolonging aging time, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

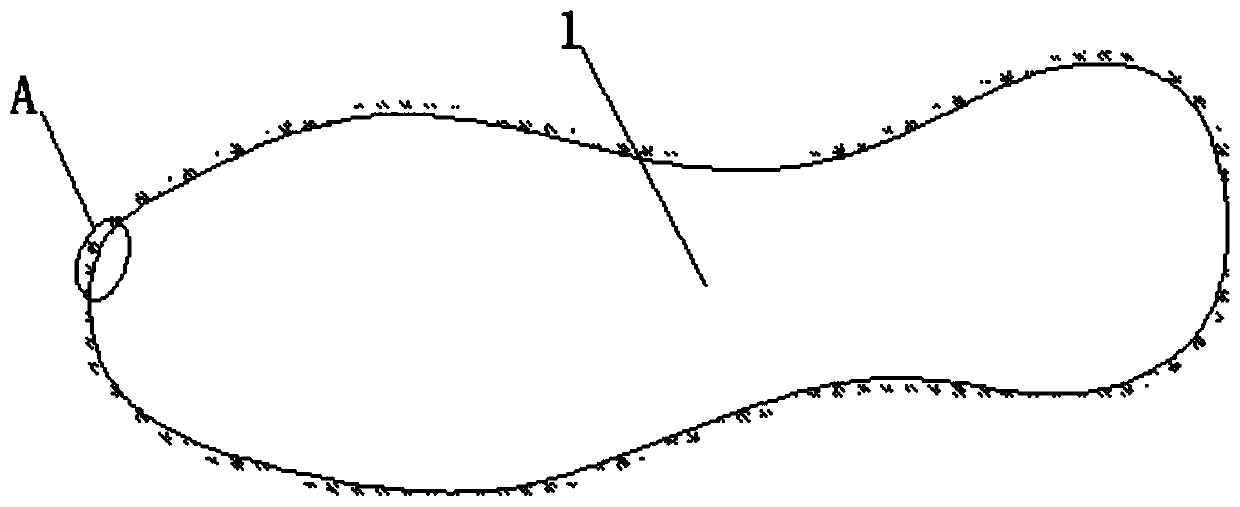

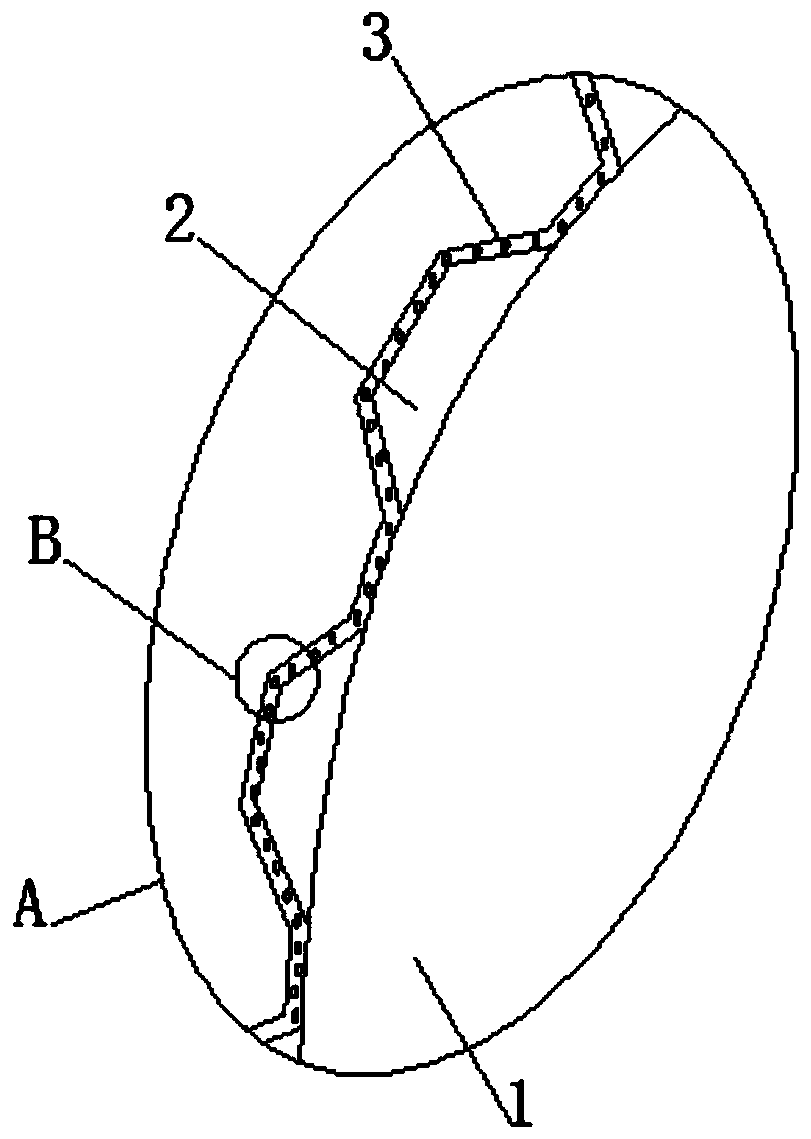

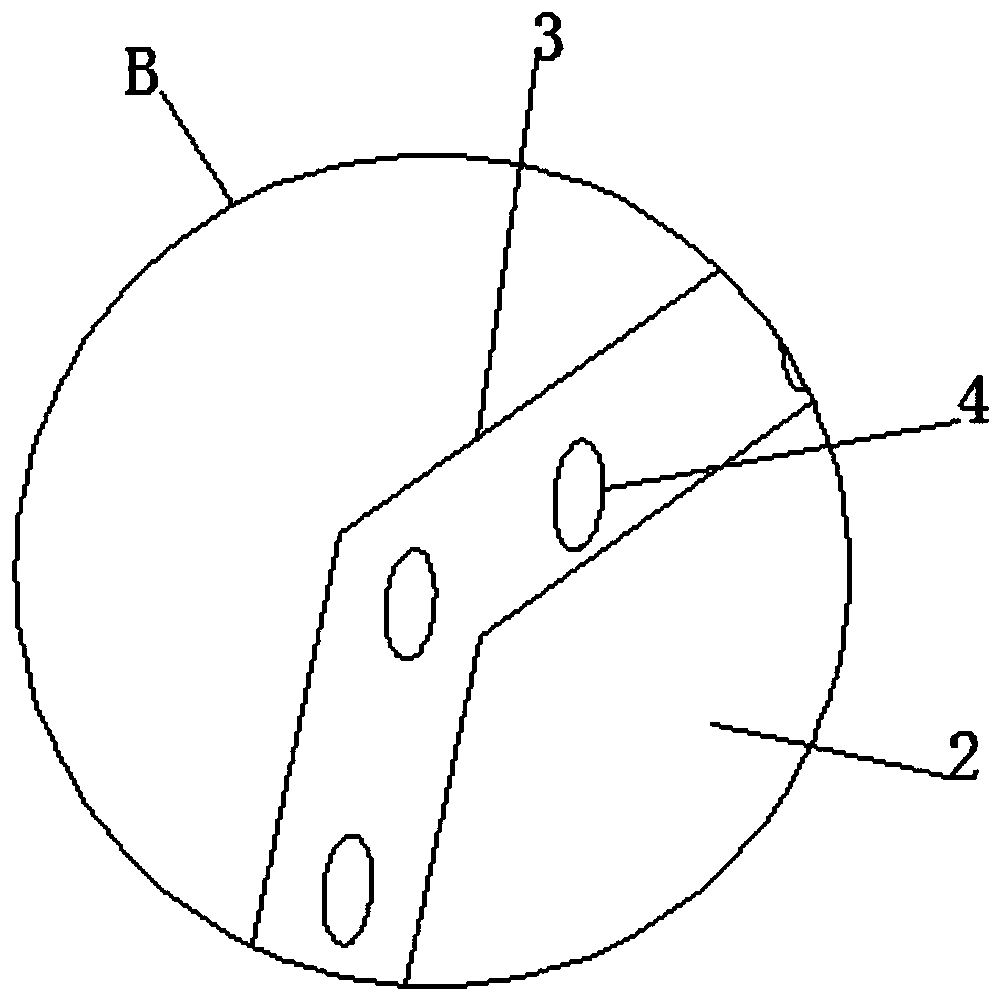

[0046] See Figure 1-2 , An anti-fouling white shoe sole, comprising a sole body 1, a plurality of uniformly distributed micro bumps 2 are fixed on the outer surface of the sole body 1, and the surface of the micro bumps 2 is a plurality of cut surfaces similar to a crystal surface, thereby increasing the micro bumps 2 The contact area with the external environment, thereby increasing its reflection of light, thereby effectively reducing the exposure of ultraviolet rays in the sun to the sole, thereby prolonging the aging time of the sole body 1 and prolonging the time for the sole body 1 to turn yellow due to aging. 1 and the surface of the micro bump 2 are equipped with outer protective cover 3, please refer to image 3 , The outer protective cover 3 is evenly inlaid with temporary repair balls 4, and the bottom surface of the sole body 1, the lower ends of the teeth 5 and the concave elastic block 6 are sprayed with 0.1-0.3mm thick LINE-X coating, LINE-X coating It is an ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com