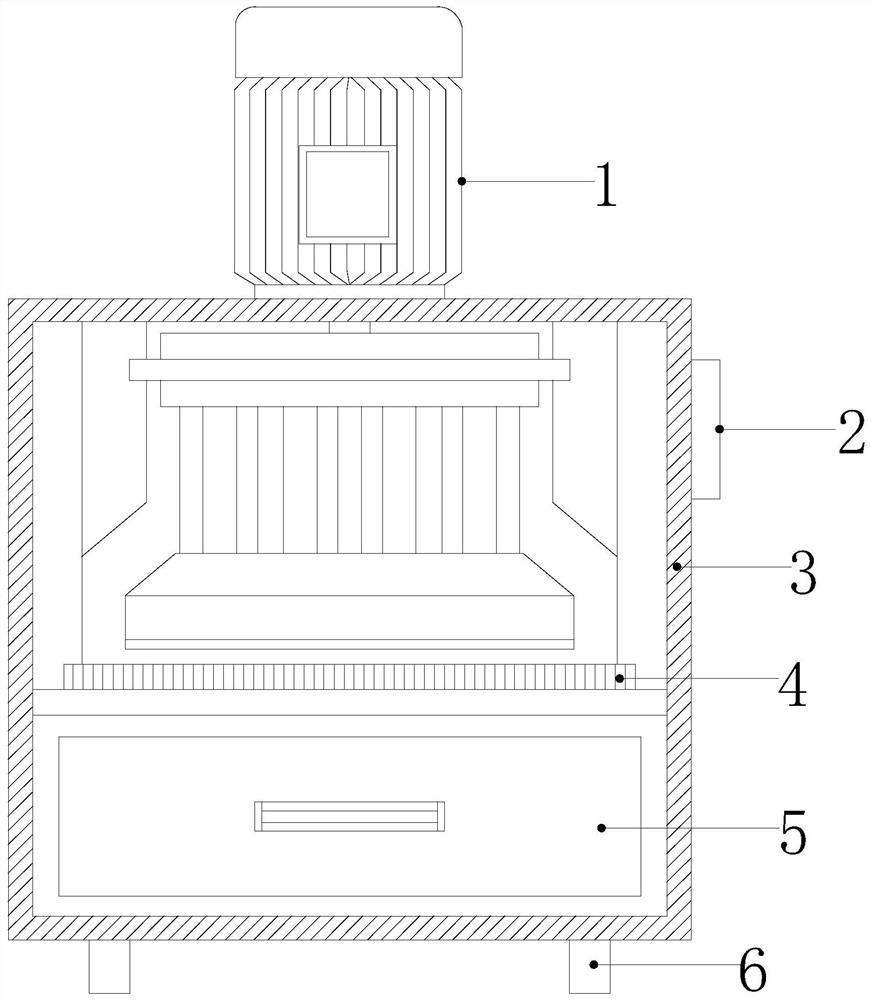

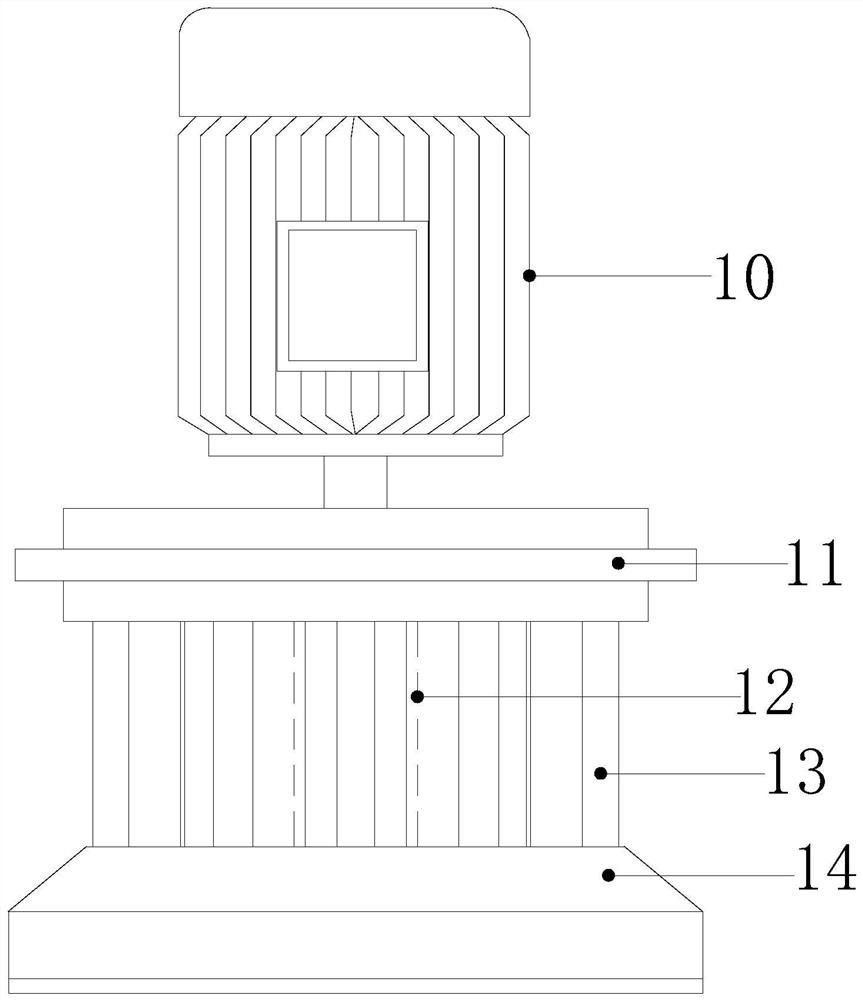

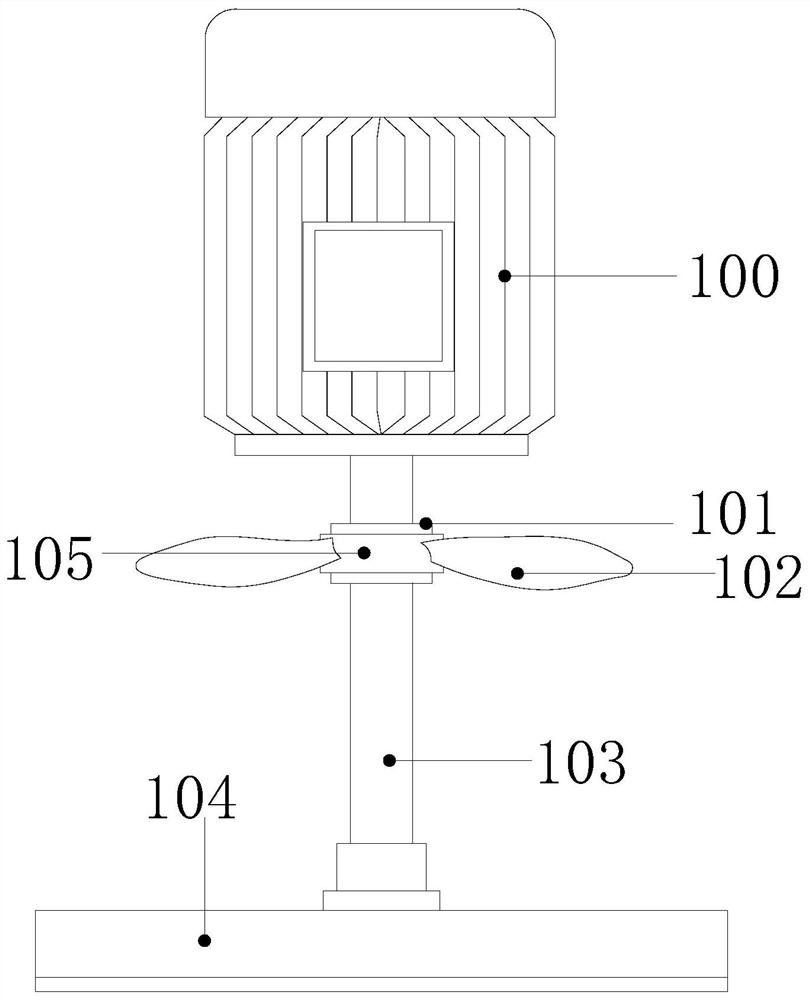

A toner safety grinder for laser printers that can prevent ozone generation

A laser printer and ozone generation technology, applied in the field of toner, can solve problems such as nasal allergies, harmfulness, human mucous membrane irritation, etc., and achieve the effect of increasing the air intake area, increasing the area of scattered air, and improving operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

[0033] In the description of the present invention, it is to be described in that, unless otherwise expressly specified and defined, the term "connected", "connection" should be used to understand, for example, may be a fixed connection, or a detachable connection, or integral Connect; may be mechanical connections or electrical connections; may be directly connected, or indirectly over the intermediate medium. The specific meaning of the above terms in the present invention wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com