Automobile door window frame

A technology for automobile doors and window frames, which is applied to doors, vehicle parts, transportation and packaging, etc. It can solve the problems of increasing the overall quality of the automobile, pores in the weld area, environmental pollution, etc., and achieve rich connection diversity and axial strength. and the effect of high modulus and improved firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

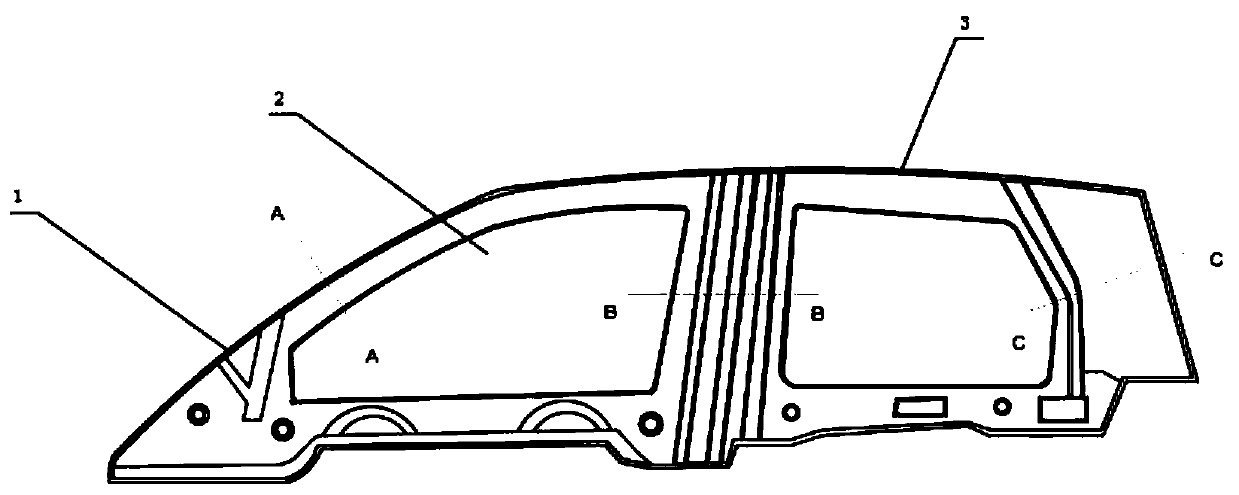

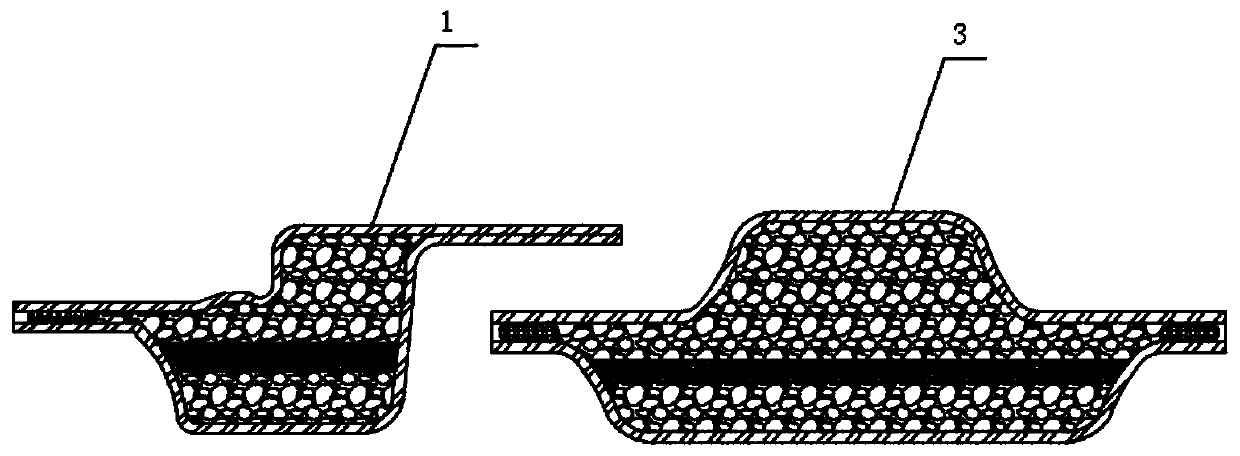

[0024] Embodiment one: refer to Figure 1-4 , a kind of automobile door window frame, comprises front-end vehicle window frame 1 and rear-end vehicle window frame 3, and front-end vehicle window frame 1 one end is fixed with rear-end vehicle window frame 3, and front-end vehicle window frame 1 and rear-end vehicle window frame 3 respectively It is composed of the inner panel 4 of the window frame and the outer panel 5 of the window frame. The front window frame 1 and the rear window frame 3 are both made of carbon fiber materials. The glass installation cavity 2, and the two glass installation cavities 2 are different in size, the front window frame 1 and the rear window frame 3 are formed as a whole by rolling and stamping welding.

Embodiment 2

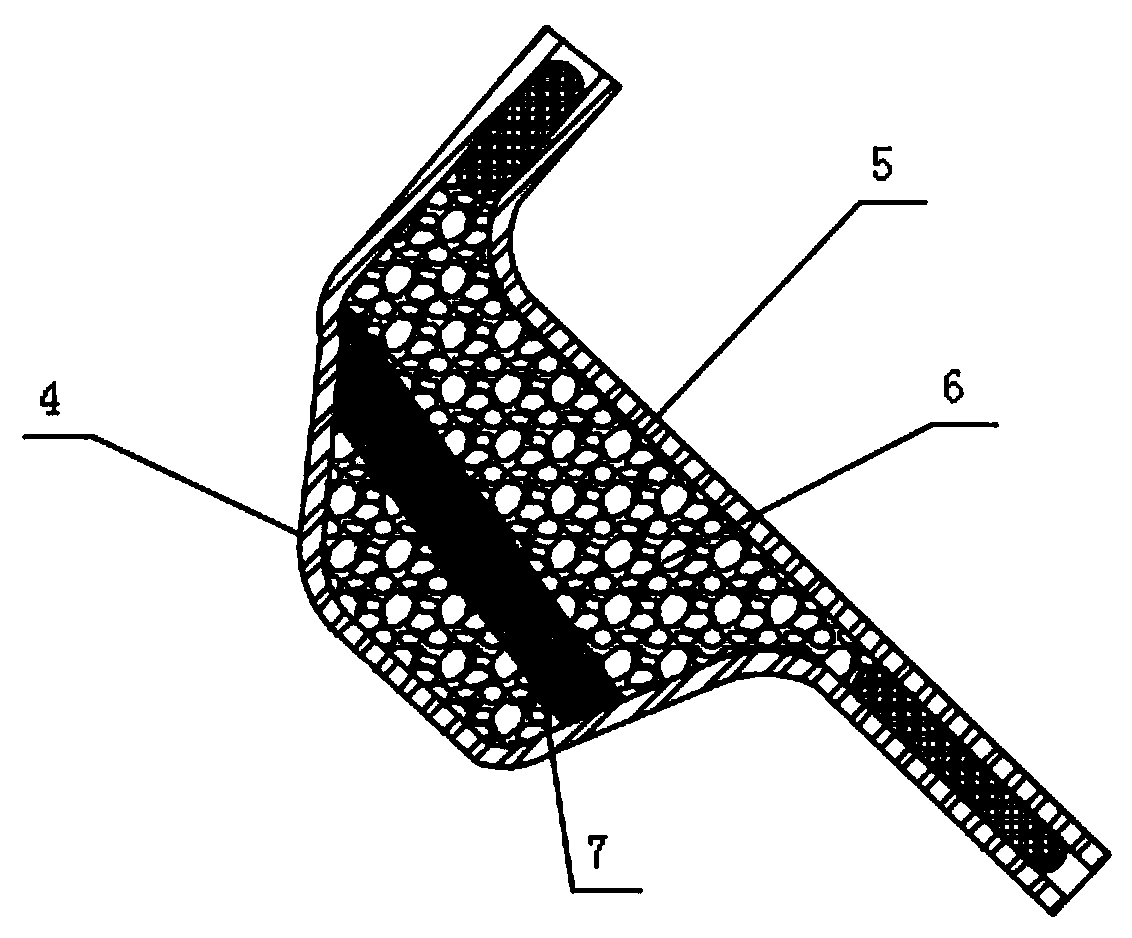

[0025] Embodiment two: refer to Figure 1-4 , one end of the window frame inner panel 4 is fixedly connected with the window frame outer panel 5 through a bending part, the other end of the vehicle window frame inner panel 4 is connected with the vehicle window frame outer panel 5 through a rivet, and the vehicle window frame inner panel 4 and the vehicle window The contact surfaces of the outer frame panels 5 are bonded together, and the outer panel 5 of the window frame and the inner panel 4 of the window frame are bonded together through the junction of the inner surfaces. Connecting holes are opened on the top to ensure the strength of the car door frame.

Embodiment 3

[0026] Embodiment three: refer to Figure 2-3 A filling layer 6 is filled between the window frame outer panel 5 and the window frame inner panel 4, and the filling layer 6 is made of a non-toxic and harmless light material, and a sound-absorbing cotton 7 is arranged between the filling layers 6, and the sound-absorbing cotton 7. The filling layer 6 is filled in layers. The filling layer 6 is a foam sandwich. The filling layer 6 not only ensures the overall strength of the car window frame, but also reduces its own weight, thereby reducing the weight of the entire vehicle. The friction between the frame and the outside air during driving and the sound generated are eliminated, thereby ensuring a quiet and comfortable environment inside the car.

[0027] Working principle: When in use, the staff first fixes the front window frame 1 and the rear window frame 3, and the car door and window frame is integrated by rolling, stamping and welding, so as to improve the overall firmness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com