A production process for preparing "ten billion" fat-derived regenerative cells

A technology for regenerative cells and fat sources, which is applied in the field of regenerative medicine, can solve the problems of high cost, less harvested culture medium, and less harvested cells, and achieve the effects of reducing total cost, increasing added value, and improving culture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

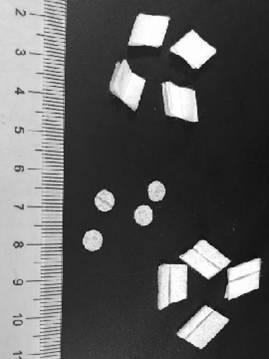

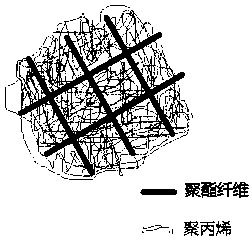

[0051] Flake carrier and preparation.

[0052] Weigh 50-150 grams of the sheet-shaped carrier that is reused for the first or second time, wash with ultrapure water, and control to dry.

[0053] Put it in a drying oven at 60°C for 24 hours to dry completely.

[0054] Each 150 grams of the sheet-shaped carrier is added to a cell culture vessel with a working volume of 3.75 liters in a German Eppendorf bioreactor, and the upper and lower parts are fixed with mesh plates to form a fixed packed bed with a volume of about 3 liters.

[0055] Pour pure water into the outer isolation interlayer of the reaction vessel, and the amount of water is half of the total interlayer volume. Add 3.75 liters of 0.01M phosphate buffer to the reaction vessel. All other parts are installed, fixed and sealed according to the manufacturer's instructions.

[0056] Move the entire fixed-bed reaction vessel into an autoclave at 121°C and autoclave for 30 minutes.

[0057] After cooling to room temperature, connec...

Embodiment 2

[0060] 150 grams of the second reused sheet carrier constitutes a 3 liter fixed packed bed.

[0061] Calculate the surface area provided by the sheet carrier: provide 1200cm per gram of sheet carrier 2 Surface area, the 150g sheet carrier used has 1.8x10 5 cm 2 The surface area.

[0062] The cell culture medium is DMEM / F12 basic medium and 10% fetal bovine serum.

[0063] Calculation of the first cell seeding volume on the first day: cell seeding density per unit area 3x10 3 Cells / cm 2 , 150g sheet carrier has 1.8x10 5 cm 2 Surface area, a total of 5.4x10 inoculated 8 Cells, calculated as a packed bed with a volume of 3 liters, the cell seeding density per unit volume is 1.8x10 5 Cells / ml.

[0064] After inoculation, the magnetic stirrer speed was set to 25 rpm, stirred for 5 minutes, stopped for 25 minutes, and repeated 4 times, that is, after 2 hours, the magnetic stirrer speed was set to continuous 25 rpm for 24 hours, and the pH of the system was maintained in the range of 7.2-7.4....

Embodiment 3

[0074] Fifty grams of flake carriers constitute a fixed packed bed of 1 liter.

[0075] Calculate the surface area provided by the sheet carrier: 1200cm per gram of sheet carrier 2 Surface area, the 50g sheet carrier used has 6x10 4 cm 2 The surface area.

[0076] The cell culture medium is DMEM / F12 basic medium and 10% fetal bovine serum.

[0077] Calculation of the first cell seeding volume on the first day: cell seeding density per unit area 6x10 3 Cells / cm 2 , 50g sheet carrier has 6x10 4 cm 2 Surface area, inoculated 3.6x10 8 Cells, calculated as a packed bed with a volume of 1 liter, the cell seeding density per unit volume is 3.6x10 5 Cells / ml.

[0078] After inoculation, the magnetic stirrer speed was set to 25 rpm, stirred for 5 minutes, stopped for 25 minutes, and repeated 4 times, that is, after 2 hours, the magnetic stirrer speed was set to continuous 25 rpm for 24 hours, and the pH of the system was maintained in the range of 7.2-7.4.

[0079] The second cell inoculation on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com