Method for separating lithium in salt lake brine through powder-type titanium ion exchanger

A technology of ion exchanger and salt lake brine, which is applied in the field of separating lithium ions in salt lake brine, titanium-based powder ion exchanger, can solve the problems of low recycling rate, low adsorption capacity, high equipment cost, etc., and achieve high cost and high cost. Adsorption capacity, effect of strict equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

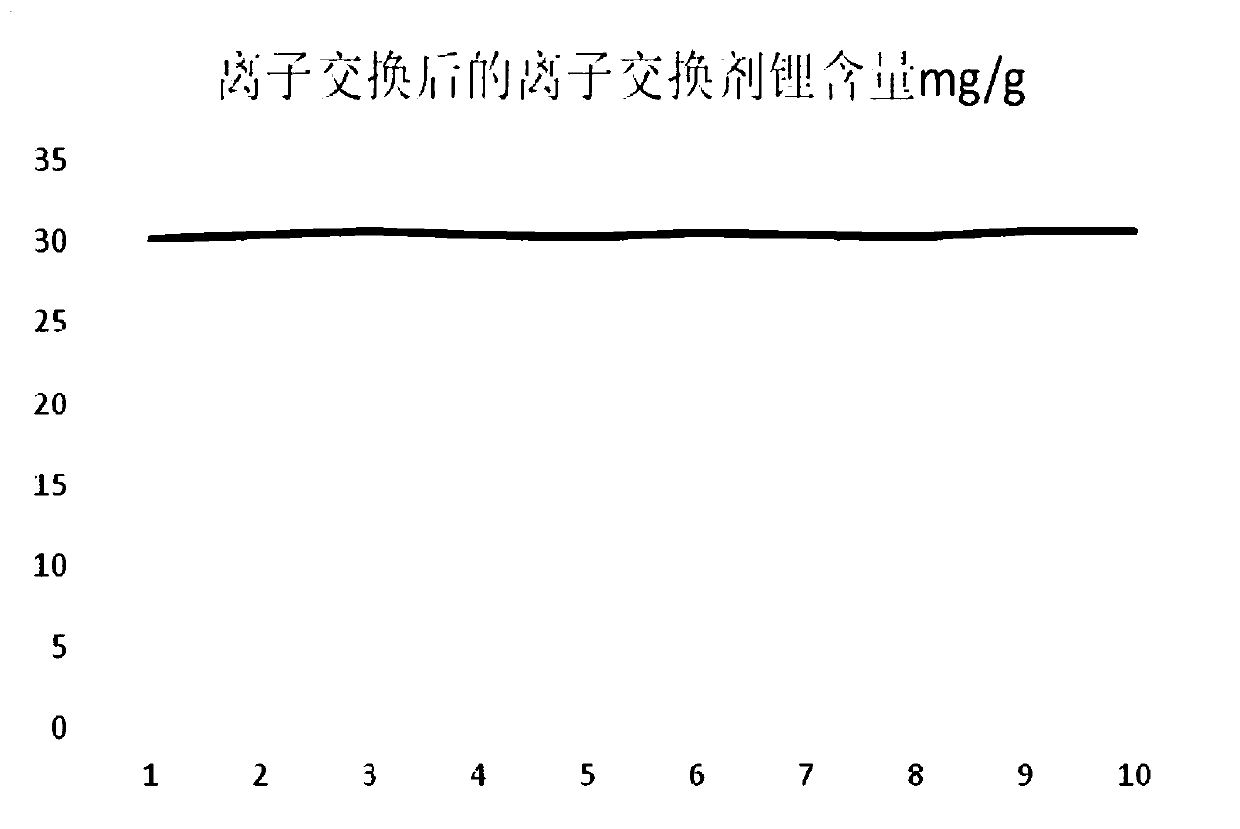

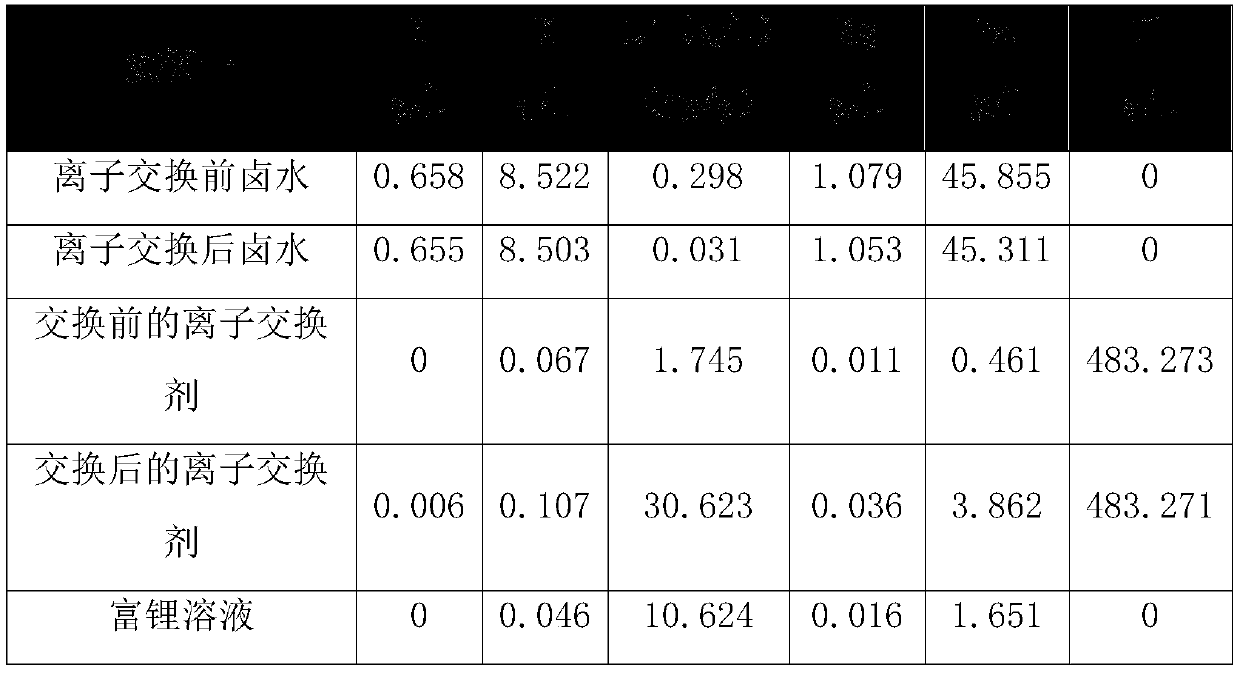

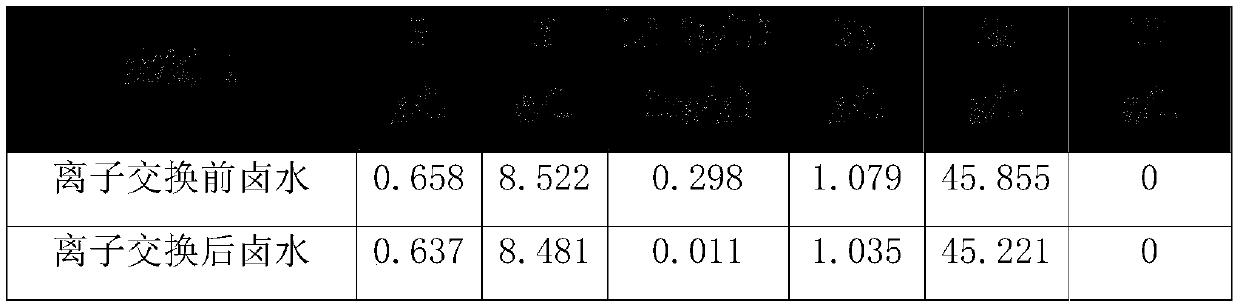

[0041] Take a certain amount of powdered titanium-based ion exchanger to make a 200g / L slurry with deionized water, heat it to 40°C in a reaction tank, slowly add the acid solution while stirring, drop the final pH to 4.5, and mature for 8 hours After filtering, repeat the operation until the Li content in the ion exchanger accounts for the TiO 2 content of 1%; use alkaline substances to adjust the alkalinity of salt lake brine to 1 times The turbidity of the filtered brine is 5JTU, put the filtered brine into the ion exchange tank; use the filtered brine to make slurry for the ion exchanger, disperse evenly and put it into the ion exchange tank, after the stirring reaction is complete, filter the slurry After solid-liquid separation, wash the filter cake with deionized water until the conductivity of the washing water is 300μs / cm; use deionized water to make a 300g / L slurry for the filter cake, heat it to 40°C in a reaction tank, and slowly add Acid solution, the pH of the ...

Embodiment 2

[0043] Take a certain amount of powdered titanium-based ion exchanger and make a 600g / L slurry with deionized water, heat it to 75°C in a reaction tank, slowly add acid solution while stirring, drop the final pH to 1.5, and mature for 5 hours After filtering, repeat the operation until the Li content in the ion exchanger accounts for the TiO 2 content of 0.5%; use alkaline substances to adjust the alkalinity of salt lake brine to 1.25 times The turbidity of the filtered brine is 2JTU, put the filtered brine into the ion exchange tank; use the filtered brine to make slurry for the ion exchanger, disperse evenly and put it into the ion exchange tank, after the stirring reaction is complete, filter the slurry After solid-liquid separation, wash the filter cake with deionized water until the conductivity of the washing water is 200μs / cm; use deionized water to make a 600g / L slurry for the filter cake, heat it to 75°C in a reaction tank, and slowly add Acid solution, the pH of th...

Embodiment 3

[0045] Take a certain amount of powdered titanium-based ion exchanger and make a 400g / L slurry with deionized water, heat it to 60°C in a reaction tank, slowly add acid solution while stirring, drop the final pH to 4.0, and mature for 2 hours After filtering, repeat the operation until the Li content in the ion exchanger accounts for the TiO 2 content of 0.01%; use alkaline substances to adjust the alkalinity of salt lake brine to 1.5 times The turbidity of the filtered brine is 3JTU, put the filtered brine into the ion exchange tank; use the filtered brine to make slurry for the ion exchanger, disperse evenly and put it into the ion exchange tank, after the stirring reaction is complete, filter the slurry After solid-liquid separation, wash the filter cake with deionized water until the conductivity of the washing water is 100μs / cm; use deionized water to make a 400g / L slurry for the filter cake, heat it to 60°C in a reaction tank, and slowly add Acid solution, the pH of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com