Supercritical water processing method for enhancing gas transportation capacity of shale matrix

A supercritical water and treatment method technology, applied in the field of energy and environment, can solve the problems of restricting gas transportation capacity and low flowback rate of fracturing fluid, so as to alleviate water phase trap damage, strong operability, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

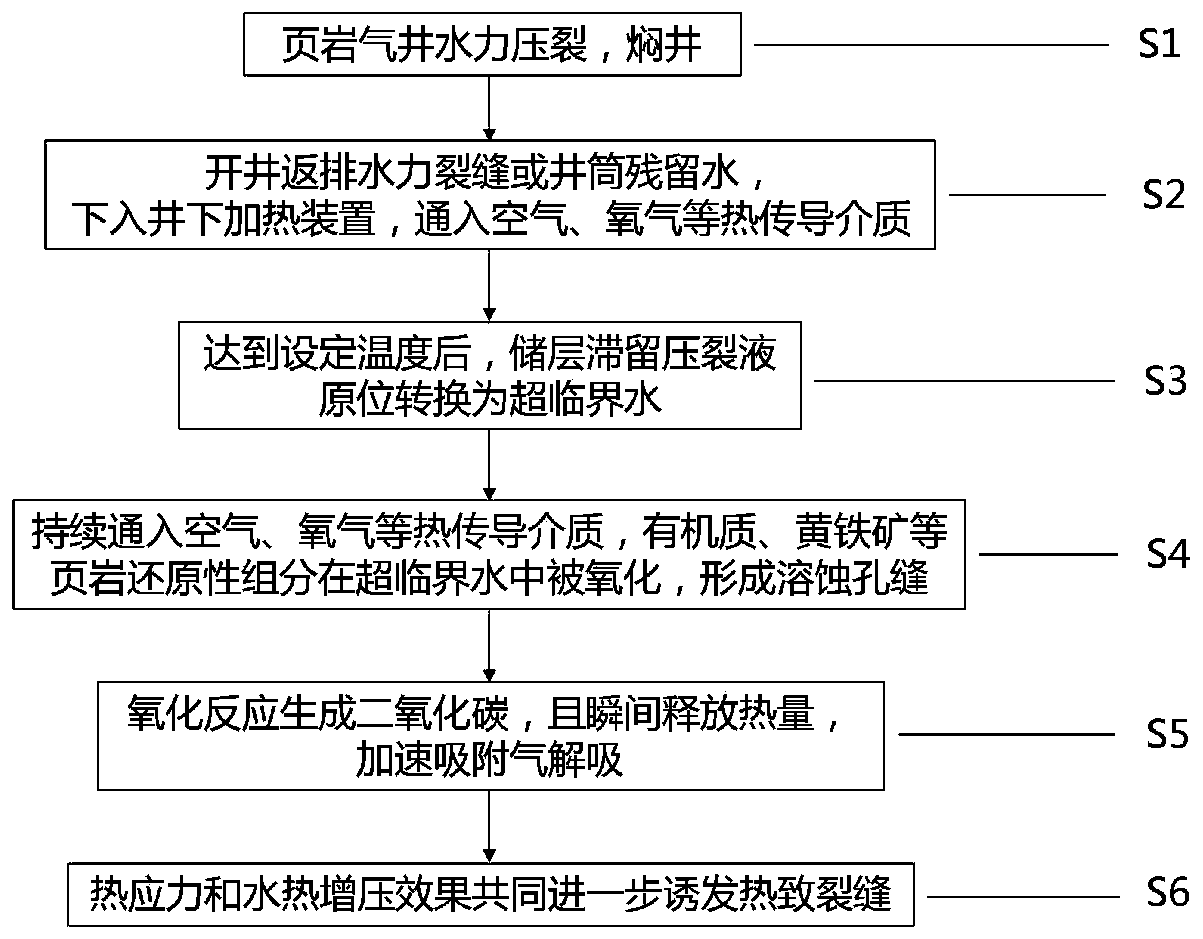

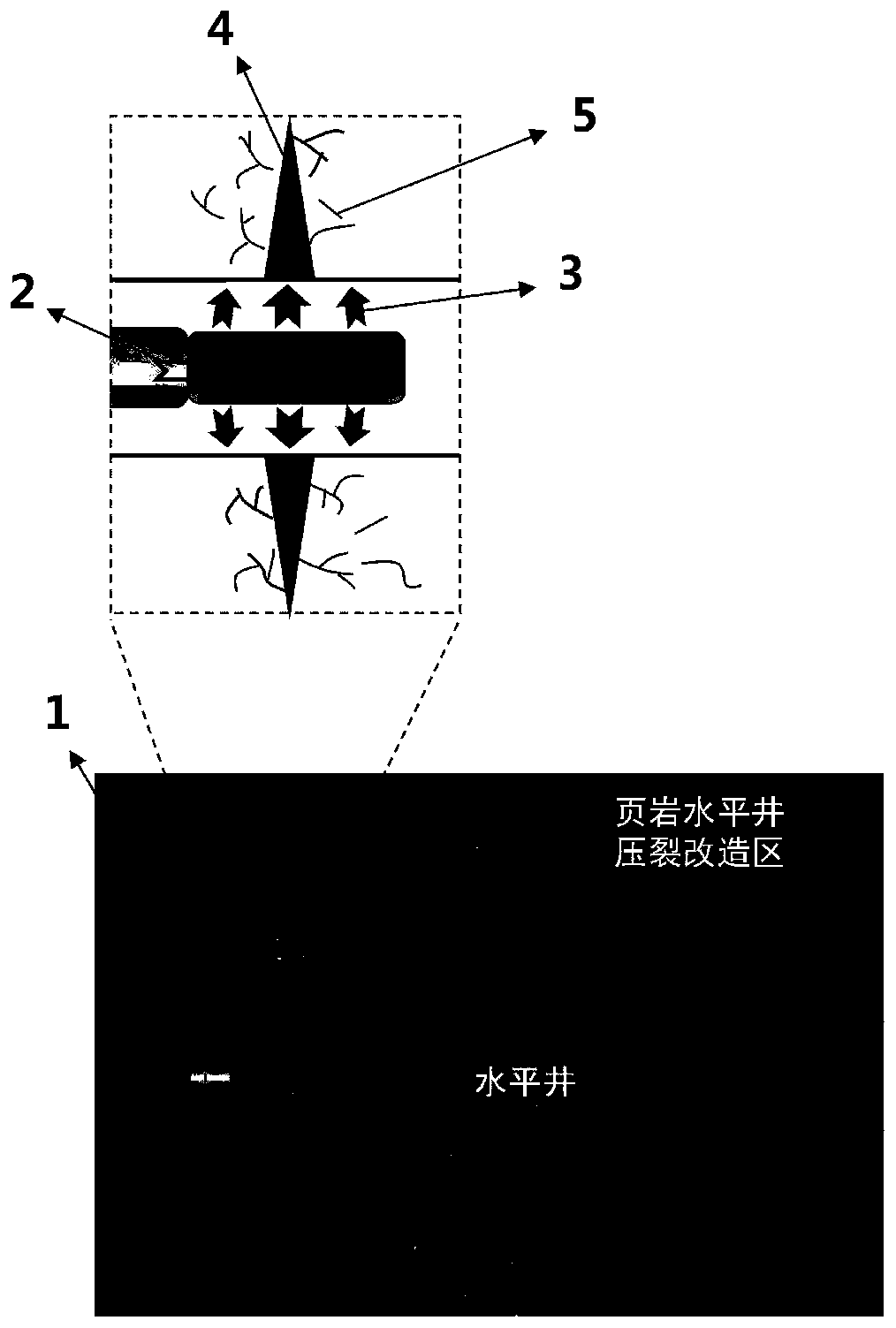

[0034] Such as figure 1 Shown, a kind of supercritical water treatment method of strengthening shale matrix gas transportation ability of the present invention, comprises the following steps:

[0035] S1. Drill at least one horizontal well in the shale gas reservoir where the original formation pressure is higher than the critical pressure value of water (22.1MPa), implement staged hydraulic fracturing on the horizontal well, and shut down the well after the fracturing operation is completed A period of time to increase the water absorption of the nanopores of the shale matrix;

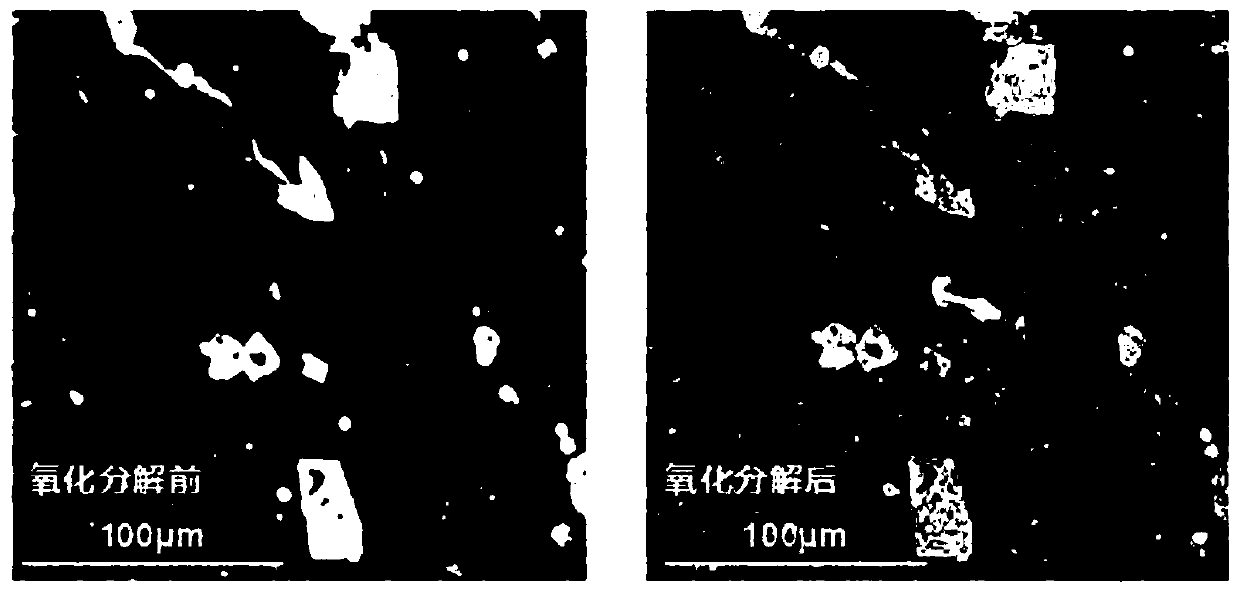

[0036] S2. In order to facilitate the implementation of downhole heating with gas as the heat transfer medium, when the daily output of fracturing flowback fluid drops significantly, the downhole heating device will be lowered into Air, oxygen or other gas oxidants are us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com