Composite purifier

A purifier and shell technology, applied in chemical instruments and methods, external electrostatic separators, electrode structures, etc., can solve the problems of high resistance, low maintenance and operating costs, and high operating and maintenance costs, and reduce the amount of entry into the side frame. opportunities, improve the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

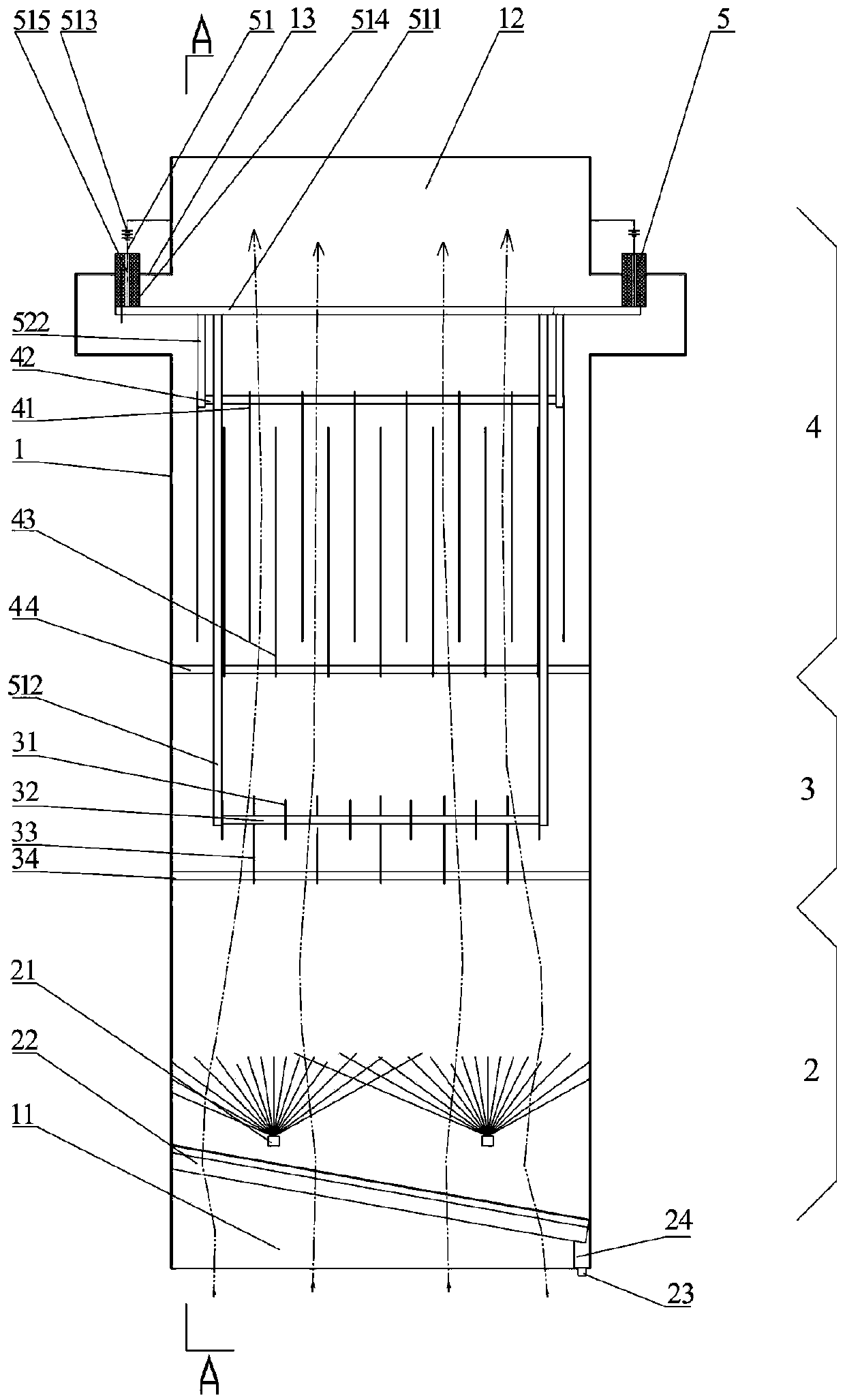

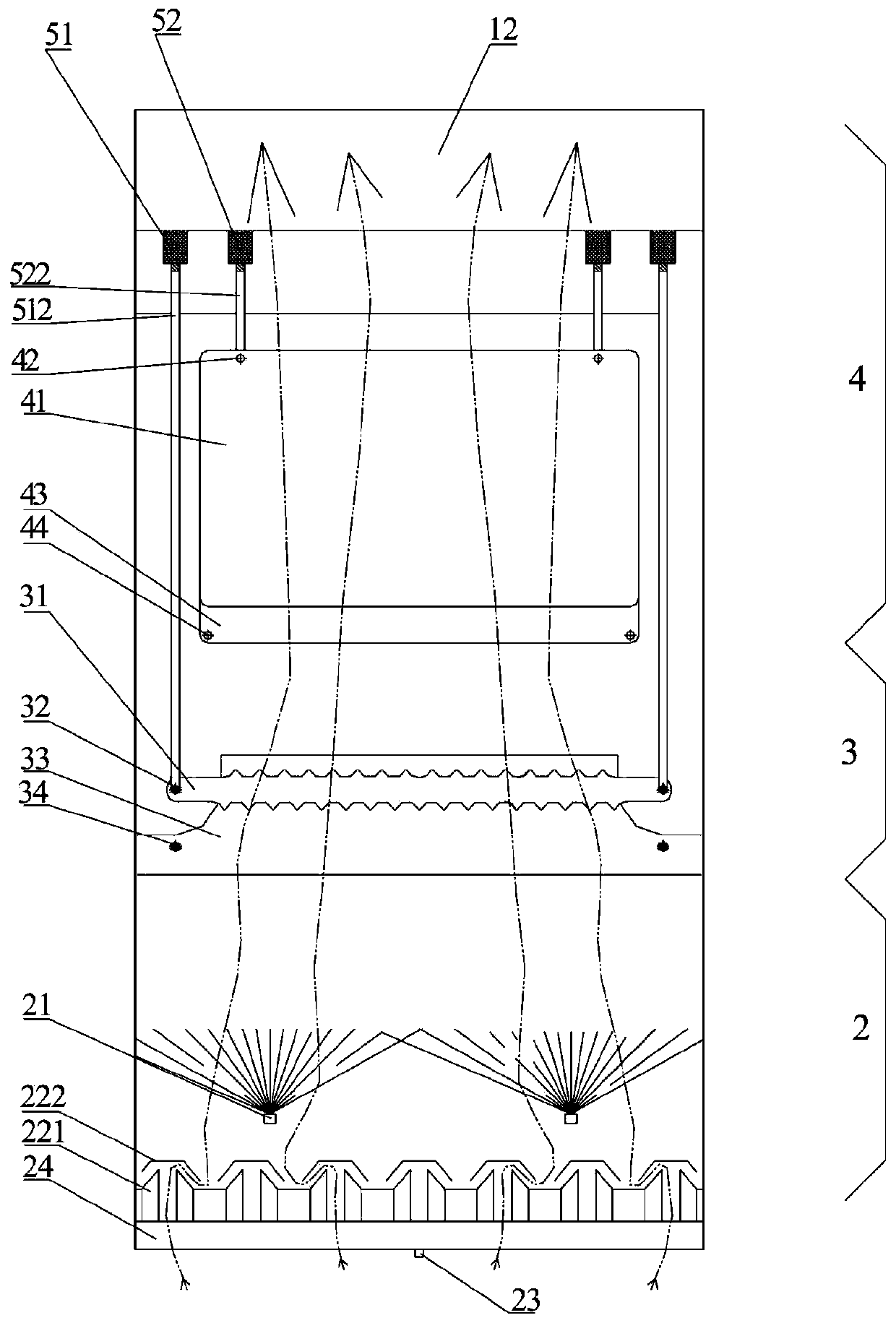

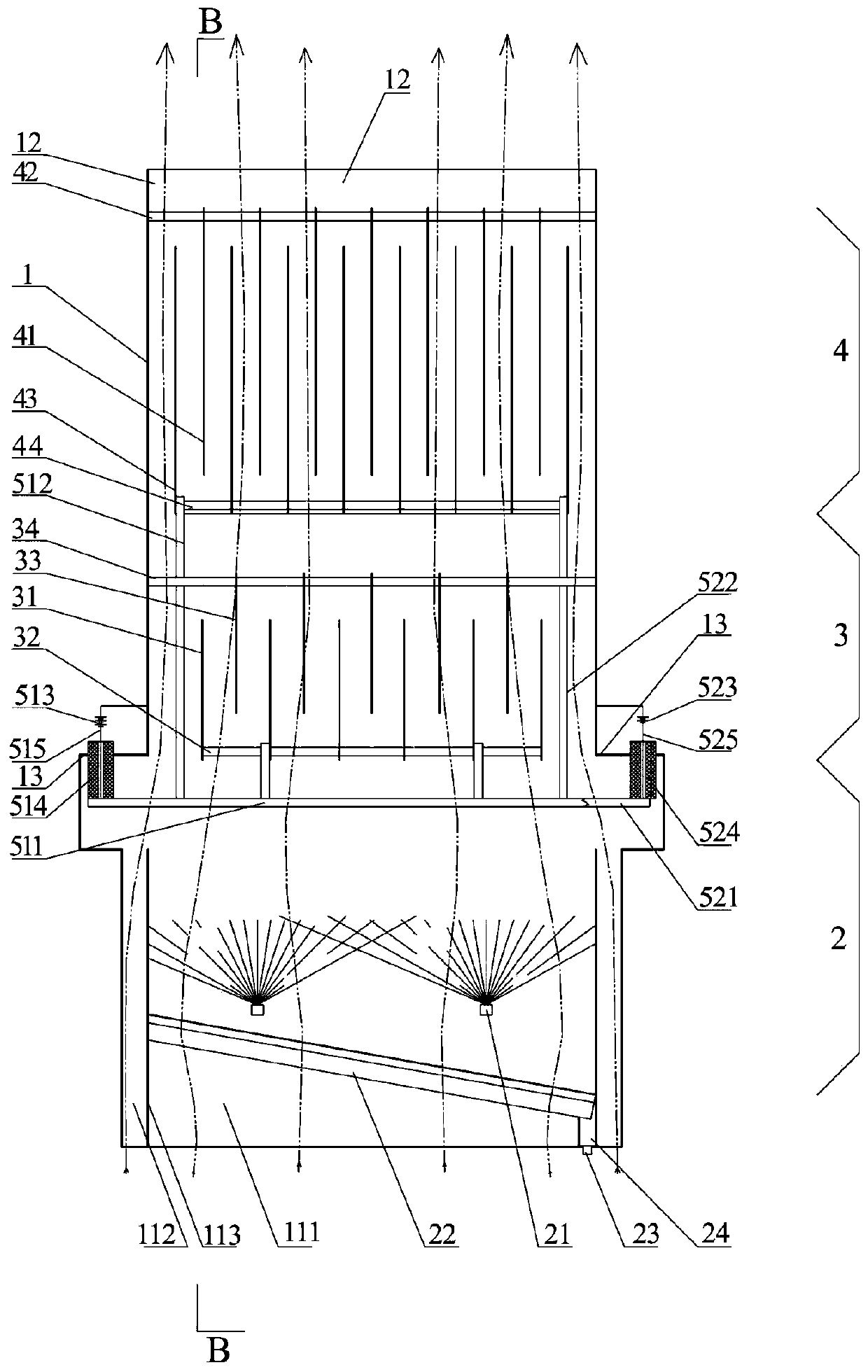

[0078] The use and working process of Embodiment 2: Under the action of negative pressure, the flue gas enters the casing 1 through the main air inlet 111 at the lower end of the casing 1 and the auxiliary air inlets 112 on both sides, and most of the flue gas enters the main air inlet 111. In the main air intake channel, the flue gas is washed by the water mist nozzle 21, part of the solid dust is wetted, the temperature of the flue gas decreases, and the gaseous oil molecules condense into a liquid state, which enters the charging area 3 with the airflow, and a small amount does not contain water mist The flue gas enters from the auxiliary air inlet 112 to prevent the water mist from splashing on the electrostatic power supply device 5 and the insulator, and also enters the charging area 3. By applying high-voltage static electricity to the charging area 3, the gas is charged at the corona electrode 31 and the discharge electrode plate 41. In the channel formed between them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com