Epoxy potting compound for rotary module and preparation method and application method of epoxy potting compound

A technology for rotating modules and potting materials, applied in the directions of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of undisclosed anti-cracking, anti-slung-off performance, low viscosity, etc., and achieve low cost, The effect of high mechanical strength and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

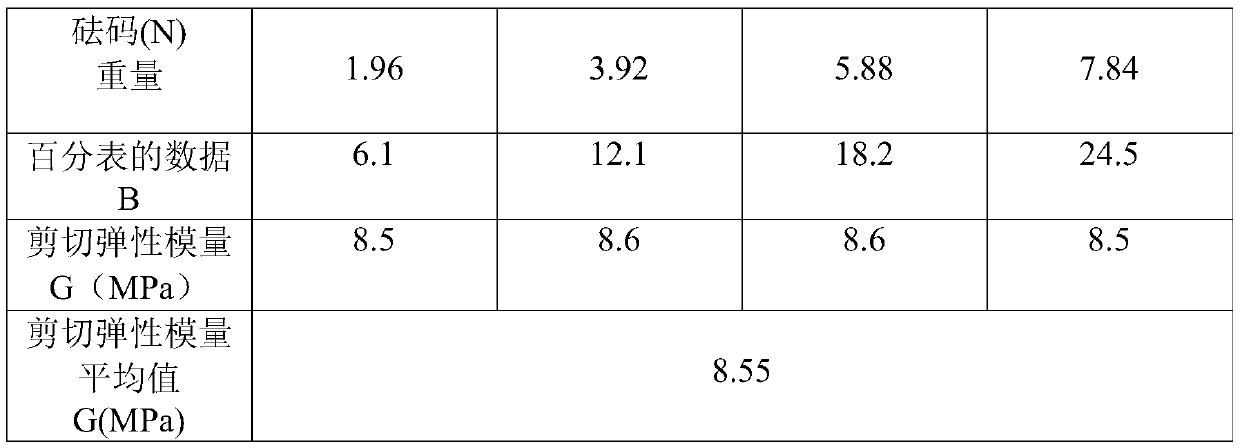

[0032] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0033] An epoxy potting compound for a rotary module, comprising epoxy resin, curing agent, silicon micropowder, talcum powder, and triethanolamine. Epoxy resin: curing agent: silicon micropowder: talcum powder: accelerator (weight ratio) = 100:75:200:20:0.5.

[0034] The epoxy equivalent of epoxy resin is 0.51.

[0035] The curing agent is an acid anhydride curing agent.

[0036] The mesh number of silica powder is 300 mesh.

[0037] The mesh number of talcum powder is 300 mesh.

[0038] The accelerator is triethanolamine.

[0039] An epoxy potting compound for a rotating module, which also includes a dyeing agent, and the weight ratio of the dyeing agent to the epoxy resin is 5:100.

[0040] A preparation method for an epoxy potting compound for a rotary module, comprising the following steps:

[0041] (1) Bake silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com