Industrial fuel with kitchen oil as raw material and preparation method of industrial fuel

A technology for kitchen and raw materials, which is applied in the field of industrial fuel and its preparation, can solve the problems such as the inability to obtain the ideal combustion effect of biofuel, the high cost of high-purity fuel, etc., and achieve the effect of improving odor and realizing filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of industrial fuel of the present invention:

[0031] Raw material ratio: 70kg of processed kitchen oil, 8kg of pure acetone, 0.1kg of fuel ethanol, 4kg of calcium oxide, 5kg of fresh pine needles with a water content exceeding 20%, and 3kg of caustic soda.

[0032] Preparation:

[0033] Step 1, mix the pine needles with caustic soda and place them in a filter bag made of asbestos sleeves for later use;

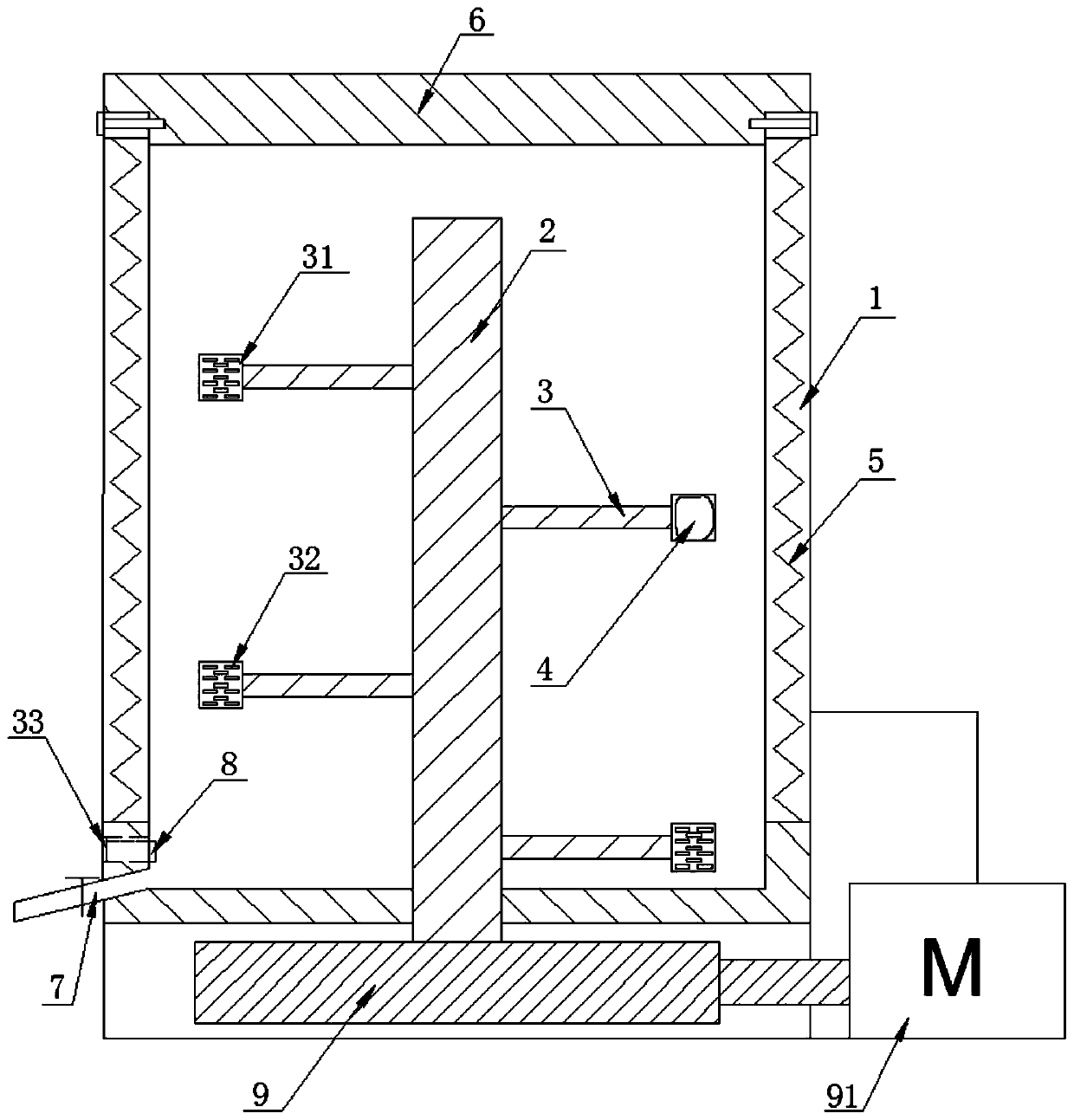

[0034] Step 2, install the filter bag with pine needles and caustic soda in step 1 on the rotating shaft of the centrifugal mixer in the fuel production device, put kitchen oil, acetone, fuel ethanol and calcium oxide in the centrifugal mixer, and make it in contact with the filter bag;

[0035] Step 3: Start the centrifugal mixer in step 2, keep it at a speed of 2800r / min for 40 minutes, and then turn off the centrifugal mixer. When the centrifugal mixer is working, its internal temperature is maintained at 60°C. After stopping, take ou...

Embodiment 2

[0038] Embodiment 2: the preparation of industrial fuel of the present invention:

[0039] Raw material ratio: 90kg of processed kitchen oil, 12kg of pure acetone, 0.3kg of fuel ethanol, 8kg of calcium oxide, 8kg of fresh pine needles with a water content exceeding 20%, and 5kg of caustic soda.

[0040] Preparation:

[0041] Step 1, mix the pine needles with caustic soda and place them in a filter bag made of asbestos sleeves for later use;

[0042] Step 2, install the filter bag with pine needles and caustic soda in step 1 on the rotating shaft of the centrifugal mixer in the fuel production device, put kitchen oil, acetone, fuel ethanol and calcium oxide in the centrifugal mixer, and make it in contact with the filter bag;

[0043] Step 3. Start the centrifugal mixer in step 2, keep it at a speed of 3200r / min for 60 minutes and then turn off the centrifugal mixer. When the centrifugal mixer is working, its internal temperature is maintained at 120°C. After stopping, take o...

Embodiment 3

[0046] Embodiment 3: the preparation of industrial fuel of the present invention:

[0047] Raw material ratio: 80kg of processed kitchen oil, 10kg of pure acetone, 0.2kg of fuel ethanol, 6kg of calcium oxide, 6.5kg of fresh pine needles with water content exceeding 20%, 4kg of caustic soda.

[0048] Preparation:

[0049] Step 1, mix the pine needles with caustic soda and place them in a filter bag made of asbestos sleeves for later use;

[0050] Step 2, install the filter bag with pine needles and caustic soda in step 1 on the rotating shaft of the centrifugal mixer in the fuel production device, put kitchen oil, acetone, fuel ethanol and calcium oxide in the centrifugal mixer, and make it in contact with the filter bag;

[0051] Step 3. Start the centrifugal mixer in step 2, keep it at a speed of 3000r / min for 50 minutes, and then turn off the centrifugal mixer. When the centrifugal mixer is working, its internal temperature is maintained at 85°C. After stopping, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com