Complex industrial process fault monitoring method based on OICA

An industrial process and fault monitoring technology, applied in the field of data-driven fault monitoring, can solve problems such as information loss, high time cost, and lack of unified standards, and achieve the goals of reducing false positives, reducing computational complexity, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Fed-batch fermentation of penicillin is a typical biochemical reaction batch process with many inter-coupling variables. Based on the improved Birol model of the Bajpai mechanism model, Professor Cinar of the Illinois Institute of Technology led the process modeling and control research group to create and develop Pensim2.0 penicillin production simulation software. This simulation platform is specially designed for the penicillin fermentation process. A series of simulations of the penicillin fermentation process can be easily realized on this platform. The process variables sampled by the Pensim2.0 simulation platform are shown in Table 1

[0054] Table 1 Process variables

[0055]

[0056]

[0057] In order to verify the fault monitoring performance of the present invention, the following types of fault data are constructed, which are specifically described in Table 2.

[0058] Table 2 Fault data

[0059]

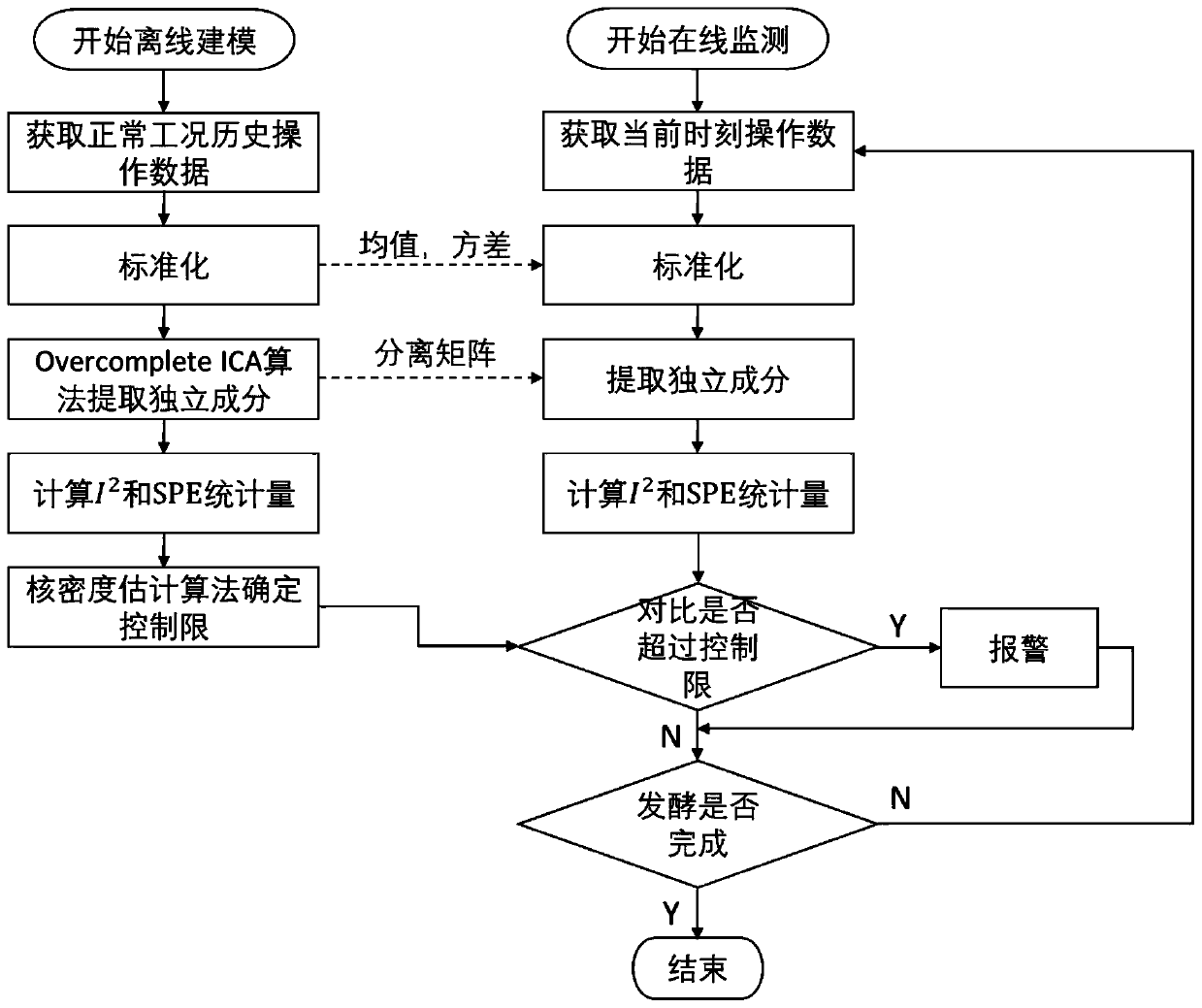

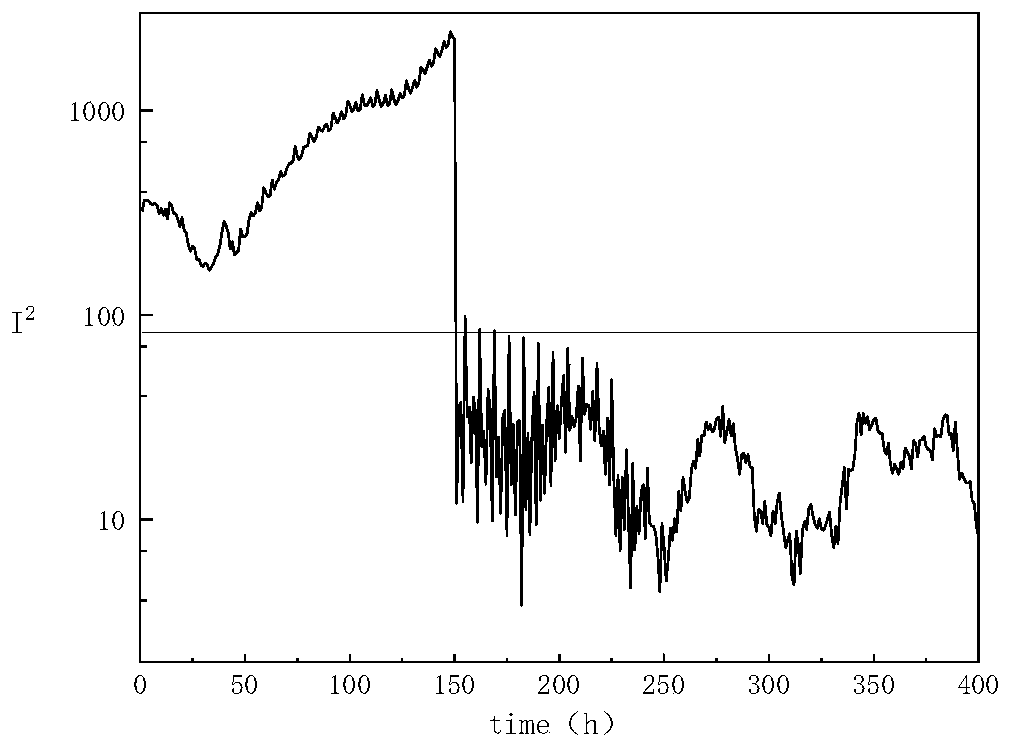

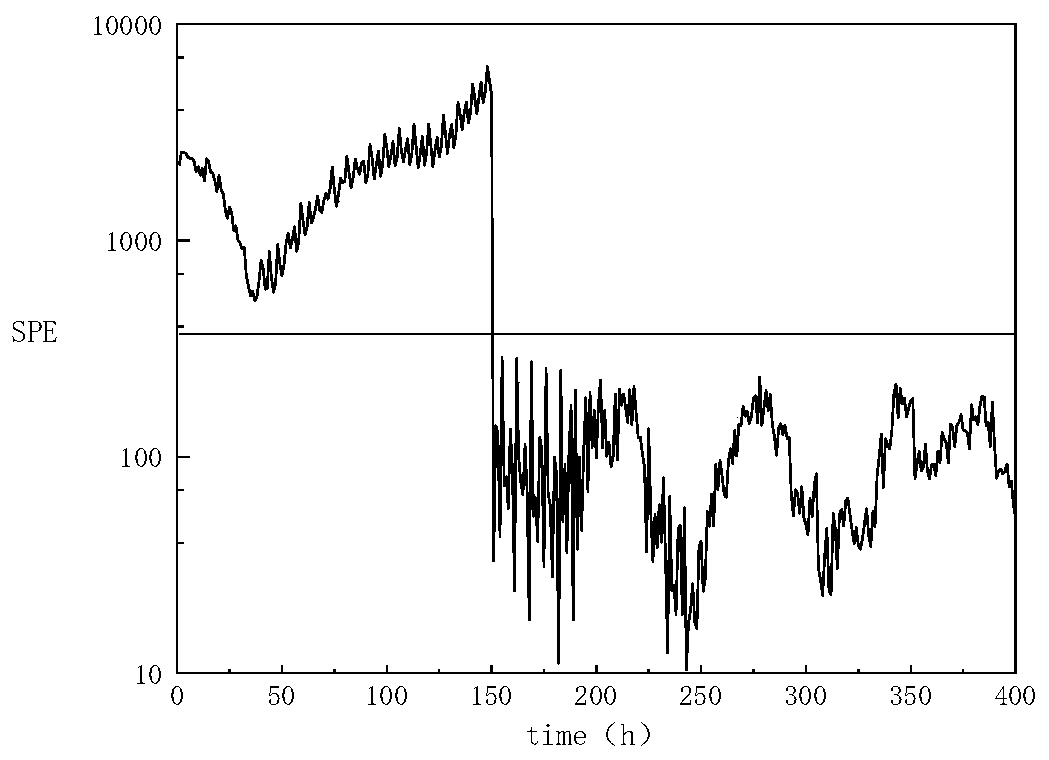

[0060] The application process of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com