Hexaflumuron water dispersible granules and preparation method thereof

A technology of diflubenzuron and dispersible granules, which is applied in botany equipment and methods, insecticides, biocides, etc., can solve the problems of no patent report of diflubenzuron, unfriendly environment, low drug content, etc., and achieve good results The effect of industrial application value, environmental friendliness, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

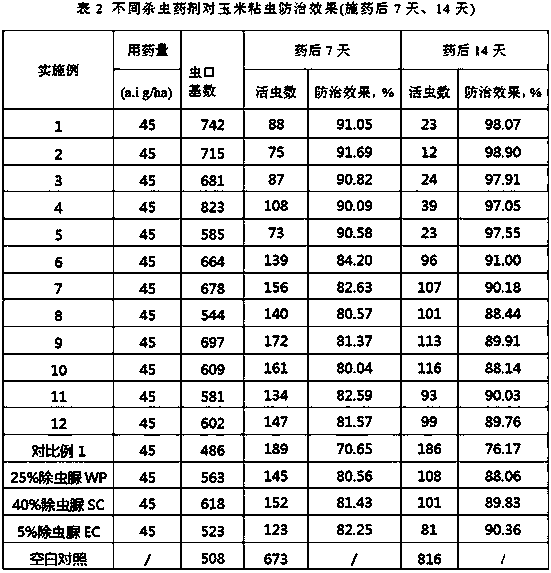

Examples

Embodiment 160

[0028] Embodiment 1 60% diflubenzuron water dispersible granule

[0029] The formula is: diflubenzuron 60%, dispersant sodium polyacrylate 3.0%, phenolsulfonic acid condensate sodium salt 3.0%, alkylnaphthalenesulfonic acid formaldehyde condensate sodium salt 1.5%, wetting agent sodium dodecylsulfonate 1.5%, sodium alkylnaphthalene sulfonate 1.5%, disintegrant potassium chloride 2.5%, ammonium sulfate 5.0%, CMS-Na 2.5%, chelating agent trisodium aminotriacetate 2.0%, calcined kaolin make up 100%.

[0030]Preparation method: put each component of the above formula into a pre-mixer and mix well (10-20 minutes), carry out ultra-fine airflow pulverization to obtain a fine powder with a particle size of 500-800 mesh, and the powdered material is mixed evenly after a second time (20-20 minutes) 30 minutes), add an appropriate amount of water (5-10%) to the mixer for kneading, granulate through an extrusion granulator, and dry at 70°C in a fluidized bed to prepare 60% diflubenzuron ...

Embodiment 280

[0031] Embodiment 2 80% diflubenzuron water-dispersible granules

[0032] The formula is: diflubenzuron 80%, dispersant sodium polyacrylate 4.0%, phenolsulfonic acid condensate sodium salt 2.0%, alkylnaphthalenesulfonic acid formaldehyde condensate sodium salt 2.0%, wetting agent sodium dodecylsulfonate 1.5%, sodium alkylnaphthalene sulfonate 1.5%, disintegrant potassium chloride 1.0%, ammonium sulfate 2.0%, CMS-Na 1.0%, chelating agent trisodium aminotriacetate 1.5%, calcined kaolin to make up 100%. The preparation method is the same as in Example 1.

Embodiment 3

[0033] Embodiment 3 75% diflubenzuron water dispersible granule

[0034] The formula is: diflubenzuron 75%, dispersant sodium polyacrylate 3.4%, phenolsulfonic acid condensate sodium salt 2.8%, alkylnaphthalenesulfonic acid formaldehyde condensate sodium salt 1.7%, wetting agent sodium dodecylsulfonate 1%, sodium alkylnaphthalene sulfonate 2%, disintegrant potassium chloride 1.0%, ammonium sulfate 3.0%, CMS-Na 2.0%, chelating agent trisodium aminotriacetate 1.0%, calcined kaolin make up 100%. The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com