Total mulberry powder and preparation method thereof

A technology of mulberry powder and mulberry leaves, which can be used in food preservation, fruit and vegetable preservation, food ingredients as taste improvers, etc. It can solve the problems of bitter taste of mulberry leaves, high sweetness of mulberries, and slow drying speed, and achieve broad market prospects , prolong the shelf life and improve the powder extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

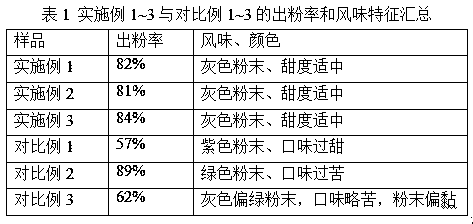

Examples

Embodiment 1

[0024] (1) Beating: Select 9 mature mulberries and mulberry leaves of 3-year-old mulberry trees in July, and beat the mulberries and mulberry leaves respectively. After treatment, the particle size of the mulberry pulp is 400-600 nanometers, and the particle size of the mulberry leaf pulp 2~3 microns;

[0025] (2) Mixing: mixing the mulberry pulp and mulberry leaf pulp after beating in step (1) evenly at a mass ratio of 4:1 to prepare a mixed slurry;

[0026] (3) Drying: The mixed slurry in step (2) is dried by centrifugal spray drying method, the inlet temperature is 150°C, the outlet temperature is controlled at 70°C, and the atomizer speed is controlled at 6000 rpm; the dried solid powder The fluidized bed is used for secondary drying, the inlet air temperature is 90°C, and the outlet air temperature is 50°C. After drying, the whole mulberry powder has a moisture content of 5wt% whole mulberry powder.

Embodiment 2

[0028] (1) Beating: Select 8 mature mulberries and mulberry leaves of 4-year-old mulberry trees in August, and beat the mulberry and mulberry leaves respectively. 1~2 microns;

[0029] (2) Mixing: mixing the mulberry pulp and mulberry leaf pulp after beating in step (1) evenly at a mass ratio of 5:1 to prepare a mixed slurry;

[0030] (3) Drying: The mixed slurry in step (2) is dried by centrifugal spray drying method, the inlet temperature is 145°C, the outlet temperature is controlled at 65°C, and the atomizer speed is controlled at 7000 rpm; the dried solid powder The fluidized bed is used for secondary drying, the inlet air temperature is 80°C, and the outlet air temperature is 45°C. After drying, the whole mulberry powder has a moisture content of 6wt% whole mulberry powder.

Embodiment 3

[0032] (1) Beating: Select 9 mature mulberries and mulberry leaves of 5-year-old mulberry trees in September, and beat the mulberries and mulberry leaves respectively. After treatment, the particle size of the mulberry pulp is 400-800 nanometers, and the particle size of the mulberry leaf pulp is 1~3 microns;

[0033] (2) Mixing: mix the mulberry pulp and mulberry leaf pulp after beating in step (1) evenly at a mass ratio of 7:1 to prepare a mixed slurry;

[0034] (3) Drying: The mixed slurry in step (2) is dried by centrifugal spray drying method, the inlet temperature is 140°C, the outlet temperature is controlled at 60°C, and the atomizer speed is controlled at 8000 rpm; the dried solid powder The fluidized bed is used for secondary drying, the inlet air temperature is 70°C, and the outlet air temperature is 40°C. After drying, the whole mulberry powder has a moisture content of 8wt% whole mulberry powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com