Villous amomum fruit processing method

A processing method and technology of amomum, applied in the field of amomum processing, can solve the problems of environmental damage and pollution, short storage time, labor and time-consuming, etc., achieve reduced storage volume and fruit bursting, simple preparation method, The effect of reducing storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

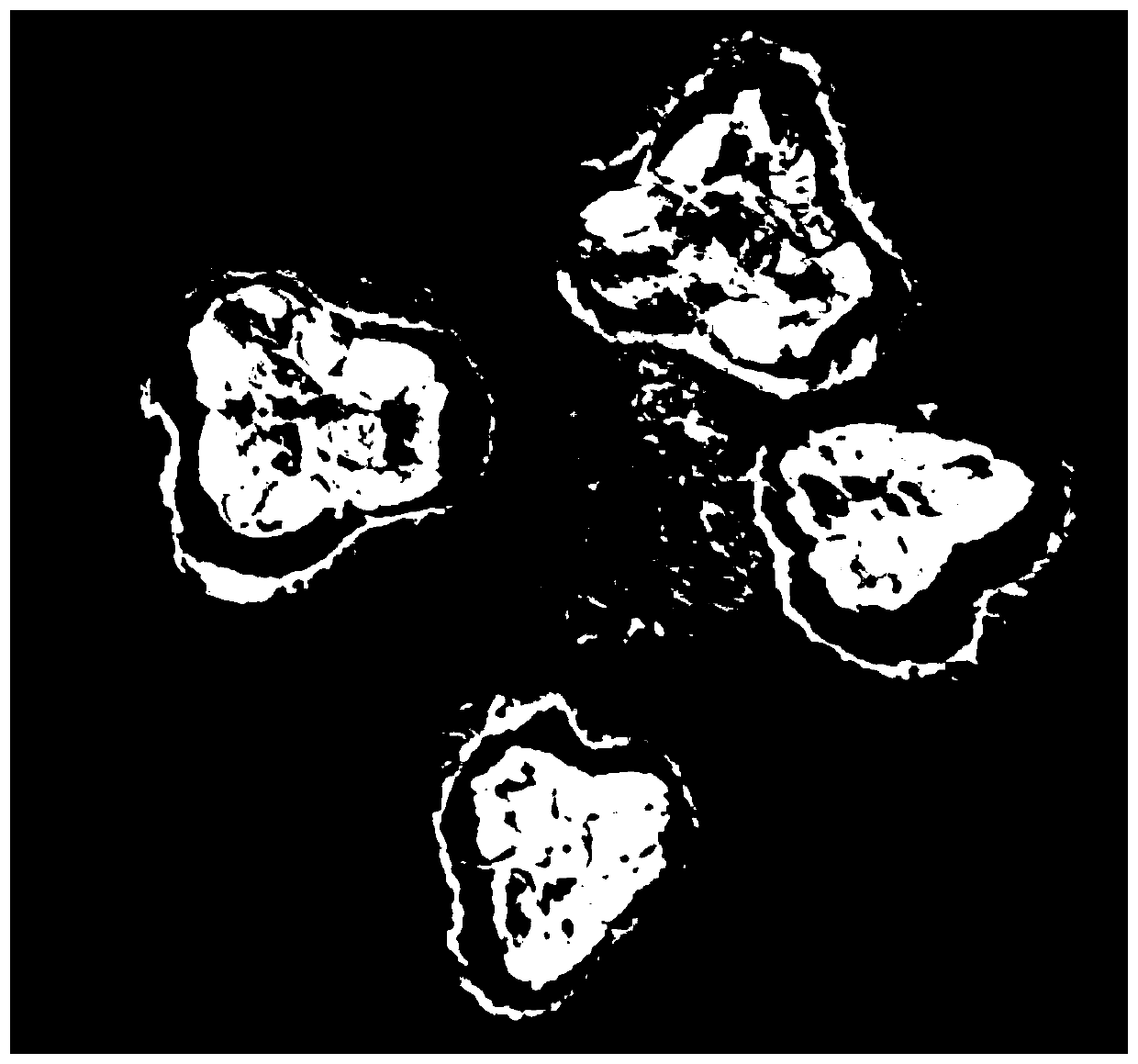

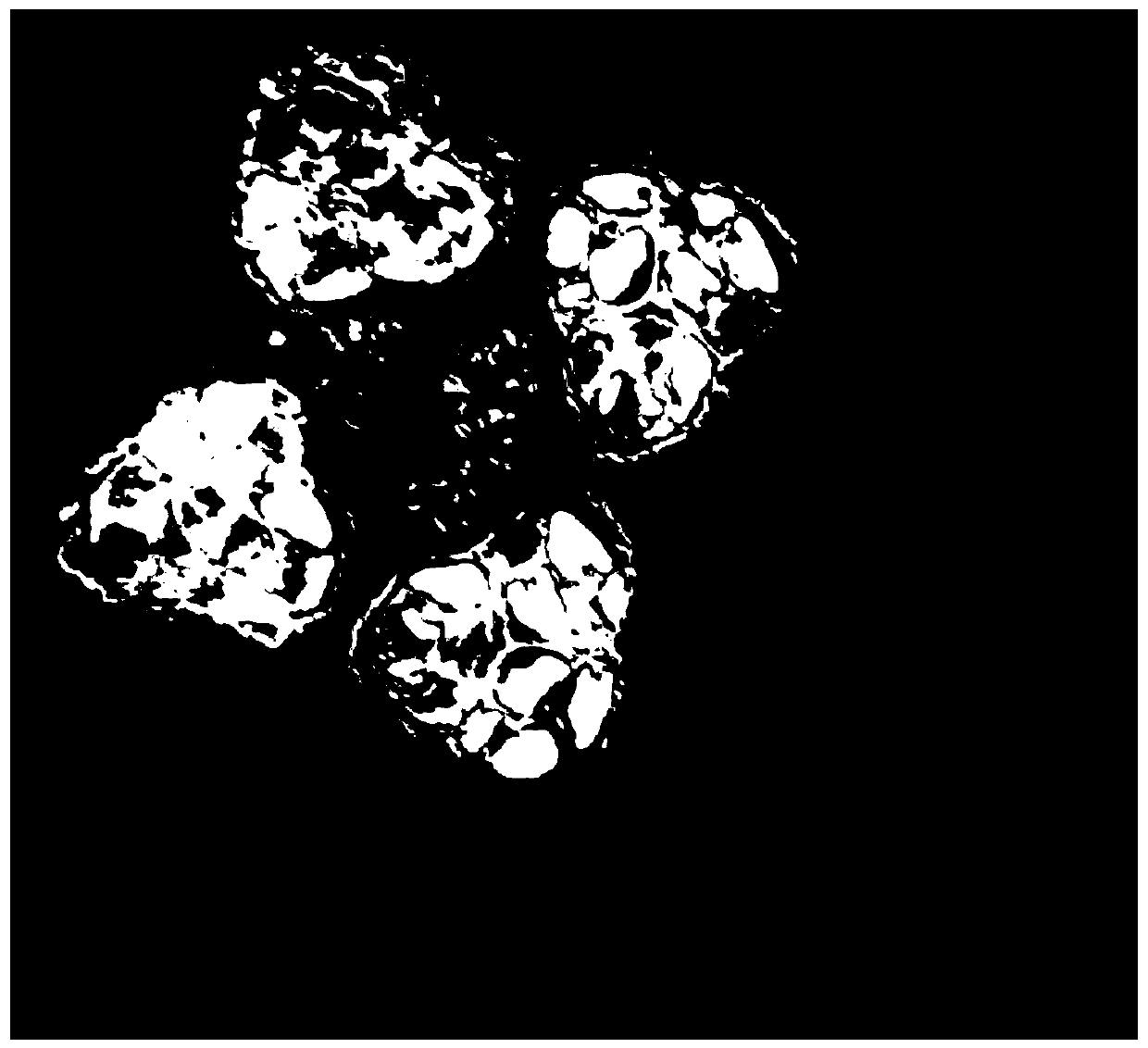

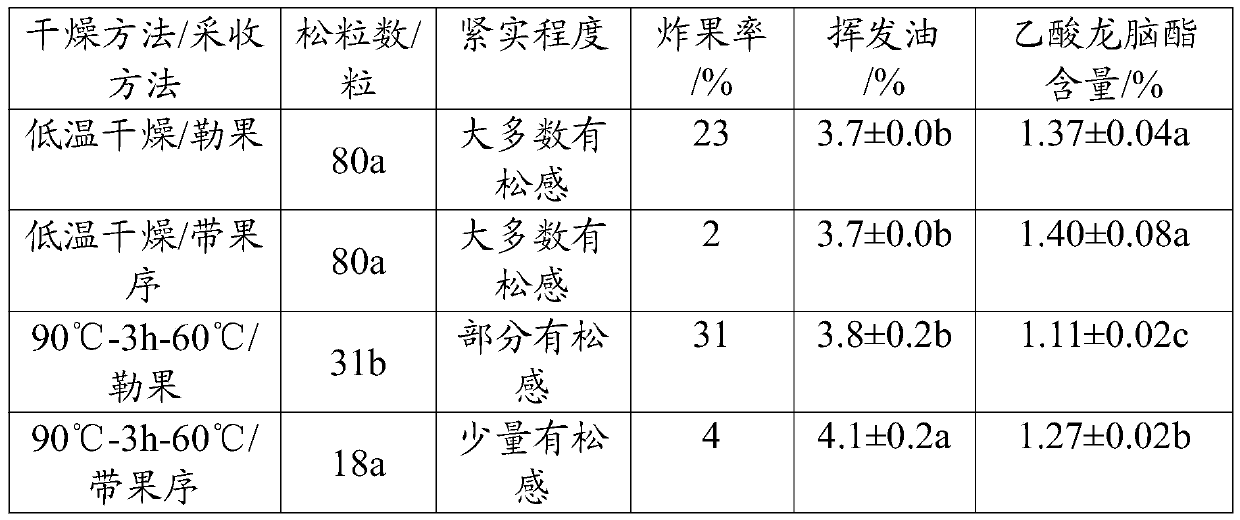

Image

Examples

Embodiment 1

[0039] The embodiment of the invention discloses a processing method of amomum, which specifically includes the following steps:

[0040] (1) Harvest: cut the whole ear, and harvest together with the infructescence;

[0041] (2) Sorting: Collect the harvested amomum in a clean, ventilated and shady place, remove weeds, sand and other impurities, use scissors to cut off rotten fruit and immature tender fruit on the top of the ear, and separate the ear Cut into spikelets or single fruit with stalk;

[0042] (3) Finishing: put the sorted amomum into the baking sieve in time, and spread it into a thickness of 4-5cm; turn on the power of the oven, set the temperature to 93°C, and when the temperature reaches 93°C, the amomum will be filled with The roasting sieve is quickly pushed into the oven; keep the oven temperature at 93°C, and carry out 5 hours of greening. When the fruit becomes soft and discolored, and water overflows when pinched by hand, push it out of the oven.

[004...

Embodiment 2

[0046] The embodiment of the invention discloses a processing method of amomum, which specifically includes the following steps:

[0047] (1) Harvest: cut the whole ear, and harvest together with the infructescence;

[0048] (2) Sorting: Collect the harvested amomum in a clean, ventilated and shady place, remove weeds, sand and other impurities, use scissors to cut off rotten fruit and immature tender fruit on the top of the ear, and separate the ear Cut into spikelets or single fruit with stalk;

[0049] (3) Finishing: Put the sorted amomum into the baking sieve in time, and spread it into a thickness of 4-5cm; turn on the power of the oven, set the temperature to 95°C, and when the temperature reaches 95°C, the amomum will be filled with The roasting sieve is quickly pushed into the oven; keep the oven temperature at 95°C, and carry out 3 hours of greening. When the fruit becomes soft and discolored, and water overflows when pinched by hand, push it out of the oven.

[005...

Embodiment 3

[0053] The embodiment of the invention discloses a processing method of amomum, which specifically includes the following steps:

[0054] (1) Harvest: cut the whole ear, and harvest together with the infructescence;

[0055] (2) Sorting: Collect the harvested amomum in a clean, ventilated and shady place, remove weeds, sand and other impurities, use scissors to cut off rotten fruit and immature tender fruit on the top of the ear, and separate the ear Cut into spikelets or single fruit with stalk;

[0056] (3) Finishing: Put the sorted amomum into the baking sieve in time, and spread it into a thickness of 4-5cm; turn on the power of the oven, set the temperature to 100°C, and when the temperature reaches 100°C, the amomum will be filled with The roasting sieve is quickly pushed into the oven; keep the oven temperature at 100°C, and carry out 2 hours of greening. When the fruit becomes soft and discolored, and water overflows when pinched by hand, push it out of the oven.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com