Preparation method of zinc sulfide cadmium solid solutions with different morphologies

A zinc cadmium sulfide, solid solution technology, applied in the field of photocatalytic materials, can solve the problems of low photocatalytic hydrogen production performance, high preparation cost, complex preparation process, etc., achieve high photocatalytic hydrogen production performance, easy control of the process, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

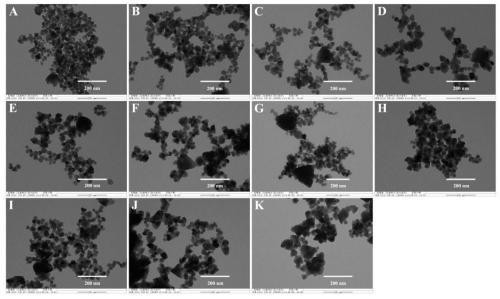

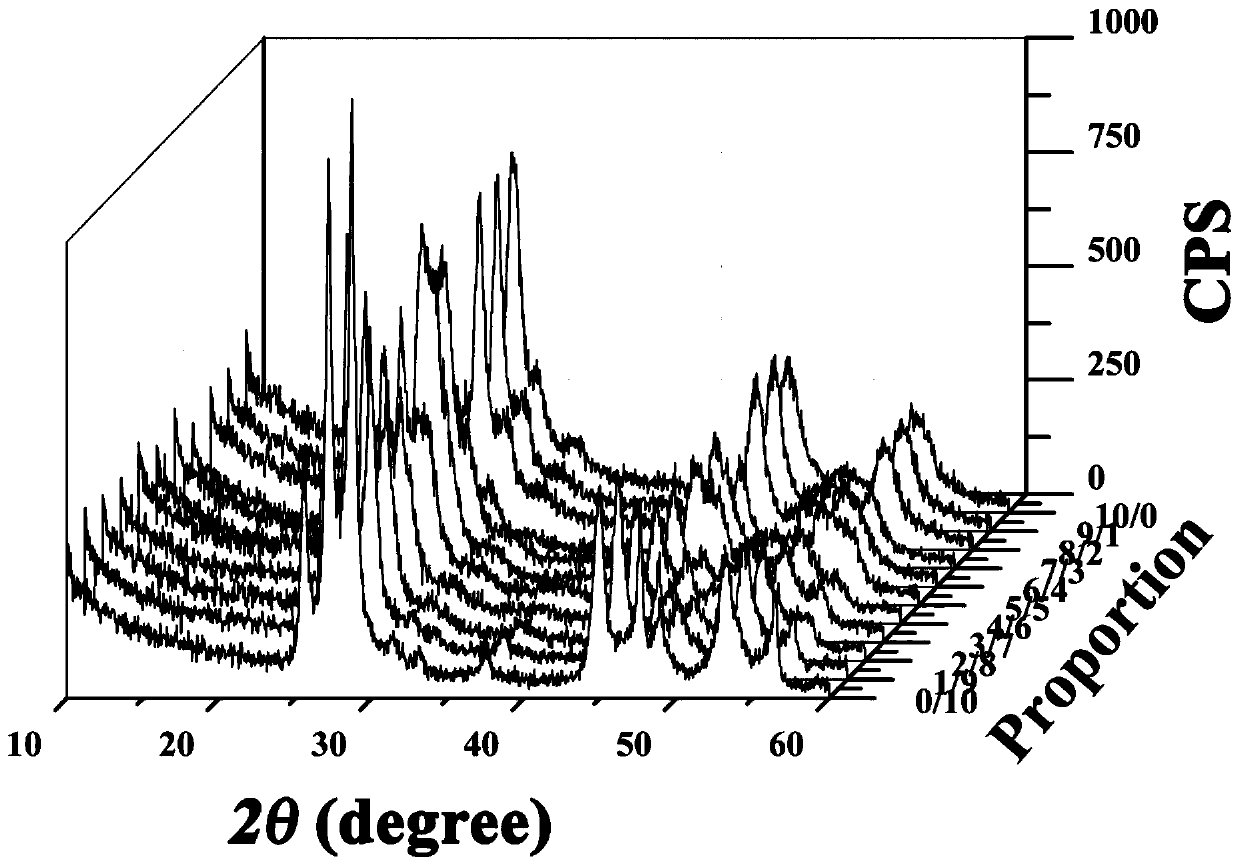

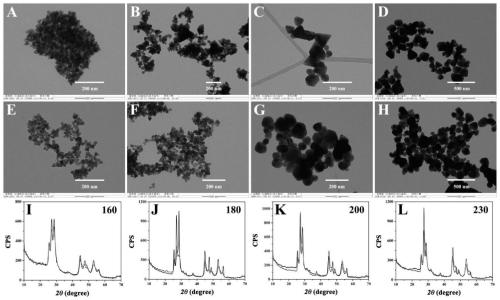

[0027] A preparation method of zinc cadmium sulfide solid solution with different shapes, which specifically comprises the following steps:

[0028] Step 1. Take L-cysteine and Zn(Ac) according to the molar ratio of 4-5:1:1 2 2H 2 O, Cd(Ac) 2 2H 2 O is dissolved in ethylene glycol or a mixed solution of ethylene glycol and deionized water, and vigorously stirred at a speed of 800 to 1000 rpm for 25 to 35 minutes to form a suspension; the volume ratio of ethylene glycol to deionized water is 1 / 9~10 / 0;

[0029] Step 2. Transfer the suspension to a polytetrafluoroethylene reactor, heat to 160°C-230°C for 23-25 hours, cool to room temperature after the reaction, centrifuge to obtain a precipitate, and use deionized water and absolute ethanol to separate After repeated washing of the precipitate, it was vacuum-dried at 55-65° C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com