Preparation method and application of red phosphorus-cladded titanium dioxide nano fiber photocatalytic material

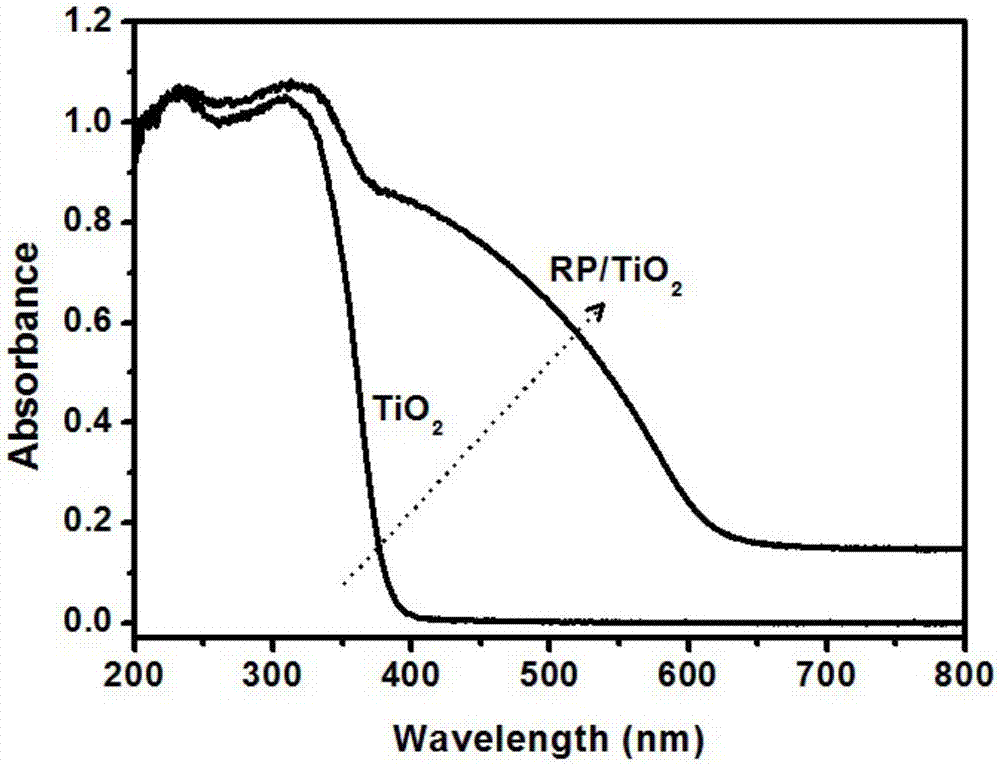

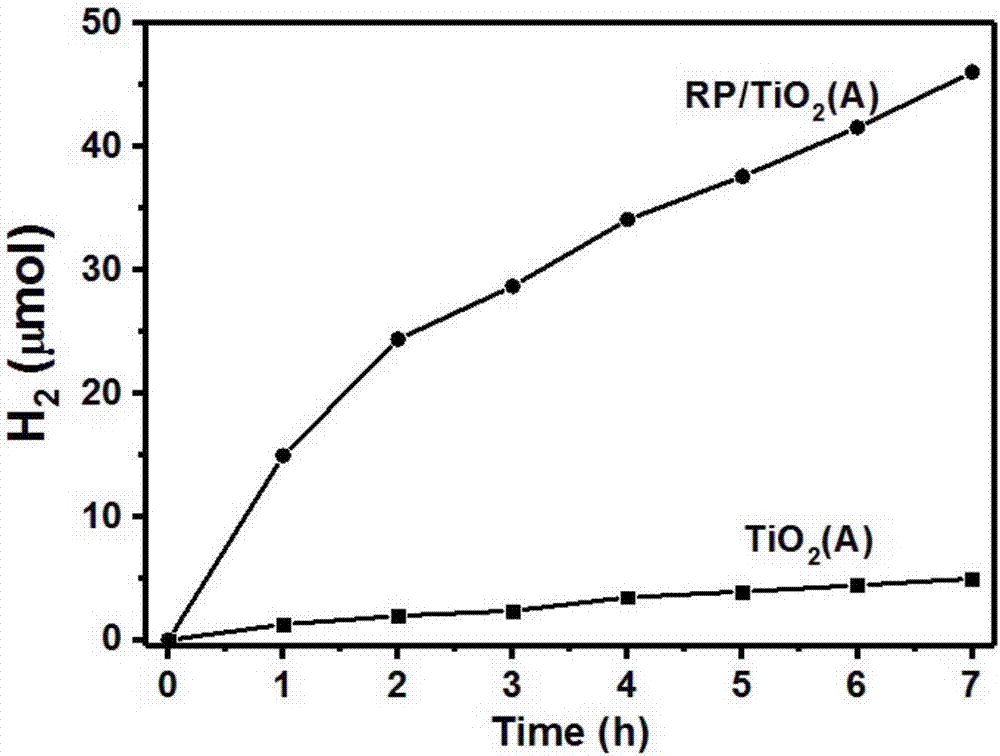

A photocatalytic material and nanofiber technology, applied in the field of photocatalytic materials, can solve the problem of low utilization rate of sunlight, achieve the effect of improving the spectral absorption range, improving the performance of photocatalytic hydrogen production, and promoting effective separation and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the red phosphorus-coated titanium dioxide nanofiber photocatalytic material of the present embodiment comprises the following steps:

[0029] a. Add 3g TiO 2 Mix anatase powder with 50ml NaOH solution, and then ultrasonically shake the mixed solution for 0.3h;

[0030] b. After the ultrasonic vibration is completed, the solution is transferred to a reaction kettle lined with polytetrafluoroethylene, and the reaction kettle is placed in an oven for hydrothermal reaction at 150°C for 45 hours. After the reaction is completed, the precursor sodium titanate nano fiber;

[0031] c, sodium titanate nanofibers are washed with deionized water, and then pickled three times with HCl solution to make Na + By H + Completely replaced, and finally titanate nanofibers are obtained;

[0032] d. Continue to repeatedly wash the titanate nanofibers with deionized water for several times until the pH value = 7, and then undergo suction filtration, drying, and...

Embodiment 2

[0037] The preparation method of the red phosphorus-coated titanium dioxide nanofiber photocatalytic material of the present embodiment comprises the following steps:

[0038] a. Add 5g TiO 2 Mix anatase powder with 80ml NaOH solution, and then ultrasonically shake the mixed solution for 0.5h;

[0039] b. After the ultrasonic vibration is completed, the solution is transferred to a reaction kettle lined with polytetrafluoroethylene, and the reaction kettle is placed in an oven for hydrothermal reaction at 180°C for 48 hours. After the reaction is completed, the precursor sodium titanate nano fiber;

[0040] c, sodium titanate nanofibers are washed with deionized water, and then pickled three times with HCl solution to make Na + By H + Completely replaced, and finally titanate nanofibers are obtained;

[0041] d. Continue to repeatedly wash the titanate nanofibers with deionized water for several times until the pH value = 7, and then undergo suction filtration, drying, and...

Embodiment 3

[0046] The preparation method of the red phosphorus-coated titanium dioxide nanofiber photocatalytic material of the present embodiment comprises the following steps:

[0047] a. Put 8g TiO 2 Mix anatase powder with 100ml NaOH solution, and then ultrasonically shake the mixed solution for 0.7h;

[0048] b. After the ultrasonic vibration is completed, transfer the solution to a reaction kettle lined with polytetrafluoroethylene, put the reaction kettle in an oven, and conduct a hydrothermal reaction at 200°C for 50 hours. After the reaction is completed, the precursor sodium titanate nano fiber;

[0049] c, sodium titanate nanofibers are washed with deionized water, and then pickled three times with HCl solution to make Na + By H + Completely replaced, and finally titanate nanofibers are obtained;

[0050] d. Continue to repeatedly wash the titanate nanofibers with deionized water for several times until the pH value = 7, and then undergo suction filtration, drying, and gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com