Method and apparatus for environmentally-friendly recycling treatment of heavy metal soil pollution

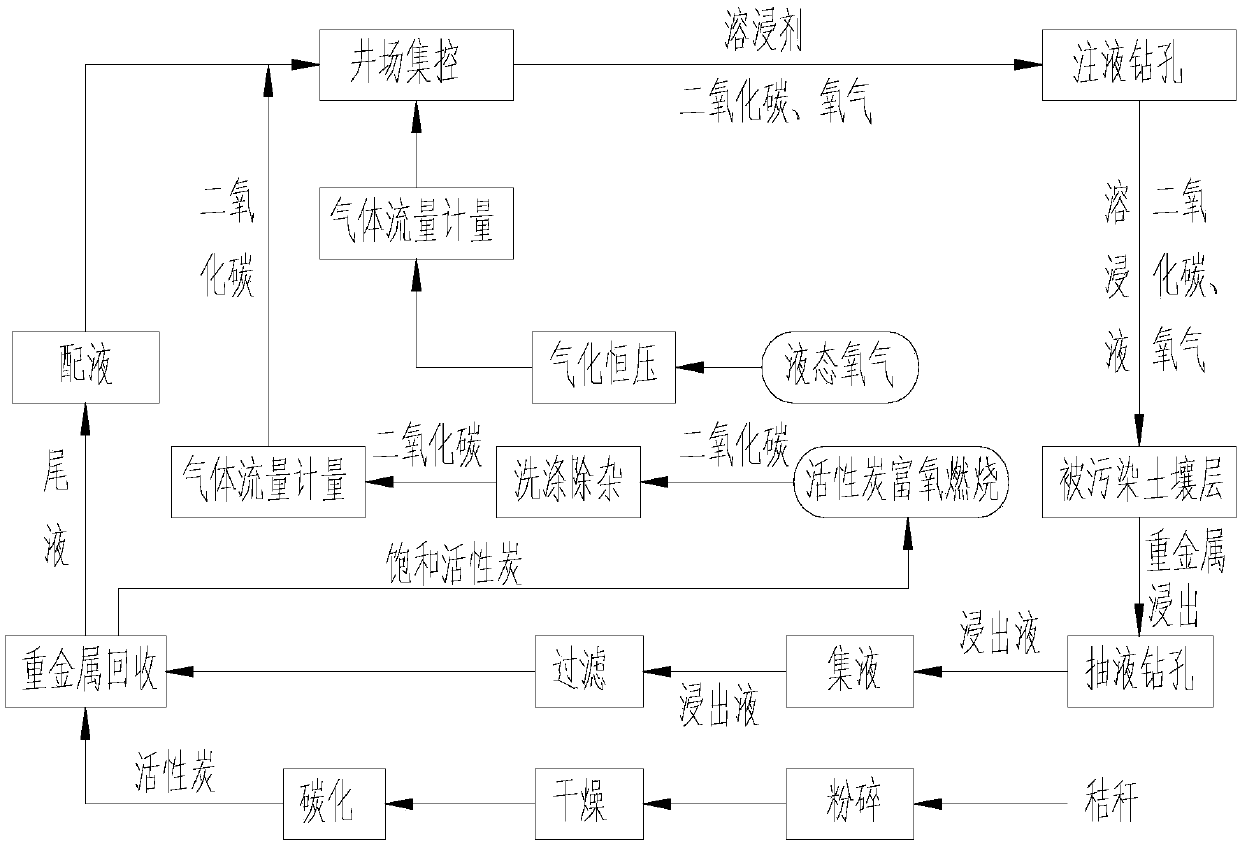

A cyclic treatment and heavy metal technology, which is applied in the field of soil pollution control, can solve the problems of lagging soil leaching technology and complete equipment development, long repair cycle and high operating costs, and achieve the effects of improving soil heavy metal activity, promoting migration and efficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

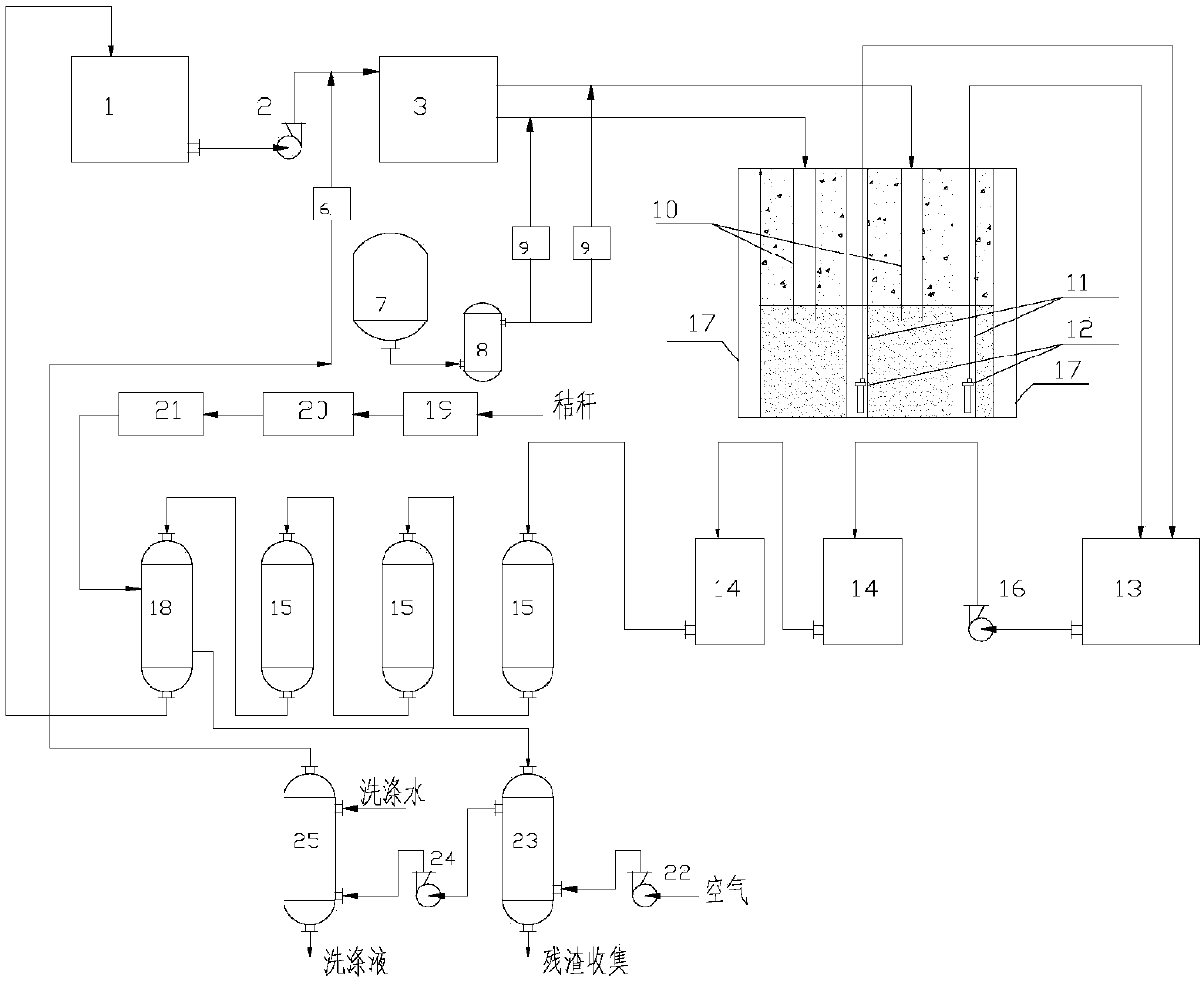

[0054] Equipment for leaching heavy metals in the soil, including liquid distribution tank (1), first centrifugal pump (2), well site control room (3), carbon dioxide flow meter (6), liquid oxygen storage tank (7), oxygen vaporizer ( 8), oxygen flow meter (9), liquid injection hole (10), liquid suction hole (11), submersible pump (12), sump (13), filter (14), ion exchange tower (15) ), the second centrifugal pump (16); wherein the outlet of the liquid distribution tank (1) is connected to the inlet of the first centrifugal pump (2) by pipes, and the outlet of the first centrifugal pump (2) is connected to the liquid injection header Enter the wellsite centralized control room (3) and divide it into liquid injection drilling branch pipes with the same number of liquid injection holes, the liquid injection drilling branch pipe is connected to the liquid injection drilling (10), the submersible pump ( 12) Set at the bottom of the pumping hole (11), the outlet of the submersible pu...

Embodiment 2

[0066] Equipment for leaching heavy metals in the soil, including liquid distribution tank (1), first centrifugal pump (2), well site control room (3), carbon dioxide source (4), carbon dioxide flow meter (6), liquid oxygen storage tank (7) ), oxygen vaporizer (8), oxygen flow meter (9), liquid injection drilling (10), suction drilling (11), submersible pump (12), sump (13), filter (14) ), ion exchange tower (15), second centrifugal pump (16), activated carbon adsorption tower (18); wherein the outlet of the dosing tank (1) is connected to the inlet of the first centrifugal pump (2) by pipes, so The outlet of the first centrifugal pump (2) is connected to the liquid injection header into the wellsite control room (3) and divided into the same number of liquid injection boreholes as the liquid injection holes, and the liquid injection borehole branch pipe is connected to the station The liquid injection borehole (10), the submersible pump (12) is arranged at the bottom of the li...

Embodiment 3

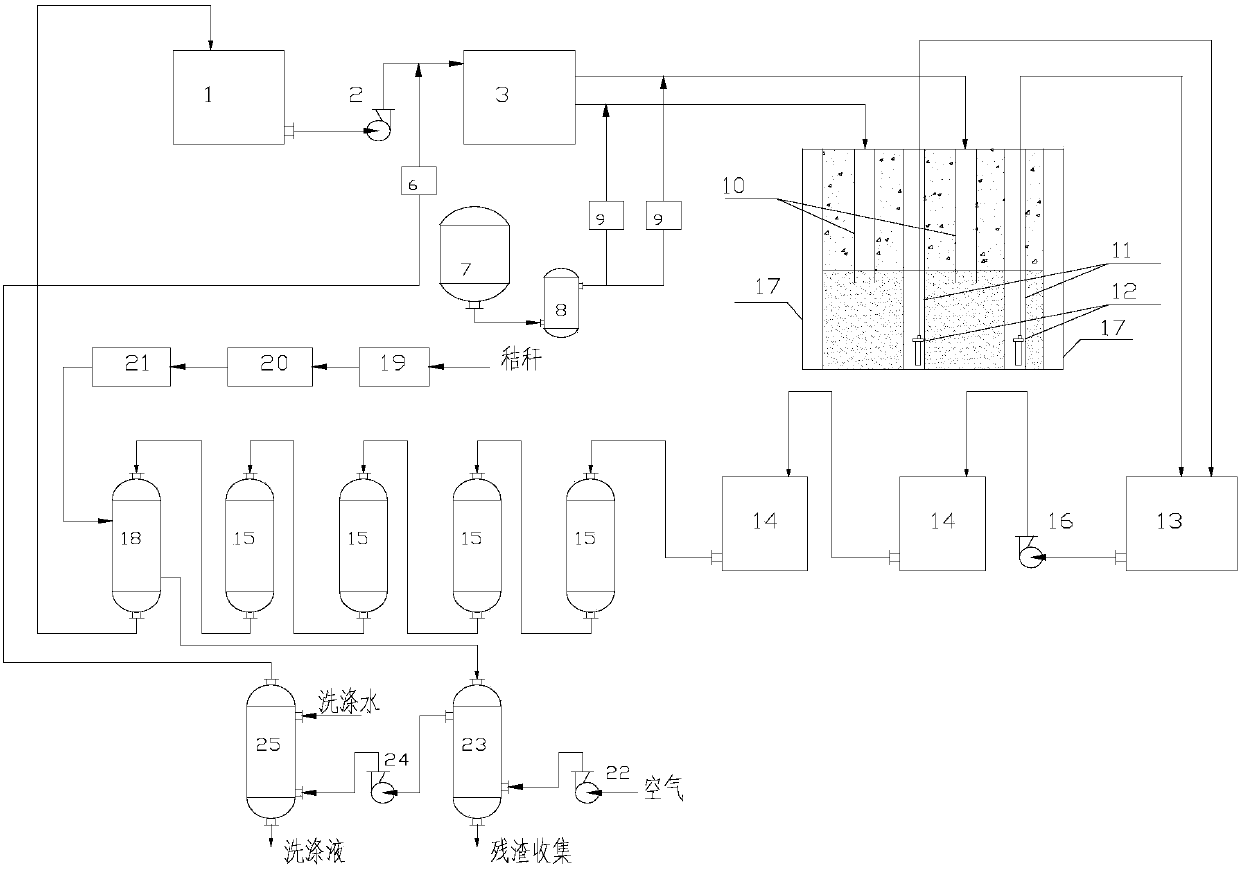

[0078] Equipment for leaching heavy metals in soil, including liquid distribution tank (1), first centrifugal pump (2), well site control room (3), liquid carbon dioxide storage tank (4), carbon dioxide vaporizer (5), carbon dioxide flow meter ( 6), liquid oxygen storage tank (7), oxygen vaporizer (8), oxygen flow meter (9), liquid injection drilling (10), pumping drilling (11), submersible pump (12), liquid collection Pool (13), filter (14), ion exchange tower (15), second centrifugal pump (16); wherein the outlet of the dosing tank (1) is connected to the inlet of the first centrifugal pump (2) by pipe , The outlet of the first centrifugal pump (2) is connected with a liquid injection main pipe to enter the wellsite centralized control room (3) and is divided into the same number of liquid injection boreholes as the liquid injection holes, and the liquid injection borehole branch pipes Connect the liquid injection borehole (10), the submersible pump (12) is arranged at the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com